What Is PCB Hardware? A Comprehensive Guide to Understanding Components and Their Roles

By: PCBBUY 03/26/2025 13:46

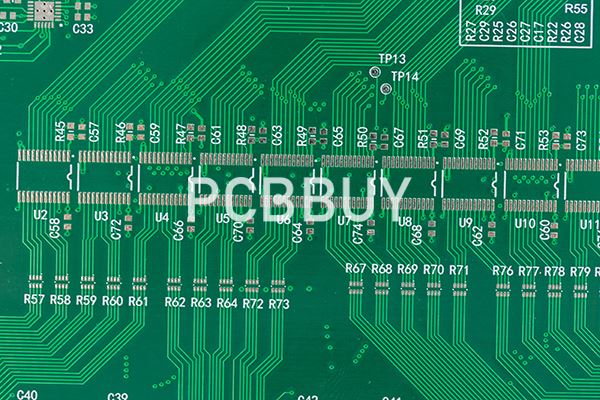

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing structural support and electrical connectivity for components. Beyond the copper traces and insulating layers, PCB hardware plays a vital role in ensuring functionality, durability, and ease of assembly. This article delves into the world of PCB hardware, explaining its importance, types, material considerations, and selection criteria.

Introduction to PCB Hardware

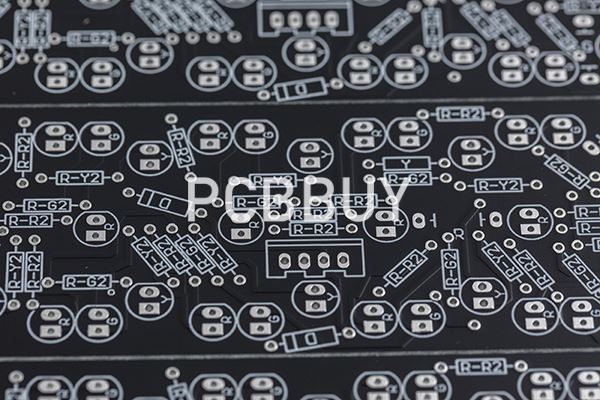

PCB hardware refers to the additional physical components used in the assembly, support, and interconnection of printed circuit boards. These include screws, standoffs, washers, spacers, and other mechanical fasteners designed to hold the PCB in place or provide electrical isolation.

Why Is PCB Hardware Important?

PCB hardware ensures:

-

Mechanical Stability: It provides structural support, preventing flexing or warping of the PCB.

-

Thermal Management: Heat sinks and specific fasteners help dissipate heat.

-

Electrical Isolation: Spacers and insulating washers maintain electrical isolation between the PCB and enclosure.

-

Ease of Maintenance: Facilitates easy assembly and disassembly during repairs or upgrades.

Types of PCB Hardware

PCB hardware encompasses a wide variety of components. Below is a detailed breakdown:

1. Standoffs

Standoffs are cylindrical spacers used to maintain a fixed distance between the PCB and its mounting surface. They come in metal or plastic variants, with threaded or unthreaded options.

-

Materials: Aluminum, brass, stainless steel, or nylon.

-

Applications: Used in enclosures to ensure PCBs don’t touch the surface, preventing electrical shorts.

-

Example Specifications: Thread size M3, length ranging from 5mm to 50mm.

-

|

Material |

Tensile Strength (MPa) |

Thermal Conductivity (W/mK) |

Electrical Conductivity |

|

Aluminum |

310-570 |

237 |

Conductive |

|

Nylon |

70-100 |

0.25 |

Insulative |

2. Screws

Screws secure the PCB to standoffs or mounting brackets. Common types include:

-

Machine Screws: Ideal for metal-to-metal connections.

-

Self-Tapping Screws: Designed for plastics and softer materials.

-

Materials: Steel, stainless steel, or nylon.

3. Washers

Washers distribute the load of a screw or bolt, preventing damage to the PCB surface.

-

Flat Washers: Provide even load distribution.

-

Insulating Washers: Made from materials like nylon or Teflon for electrical isolation.

4. Spacers

Spacers are similar to standoffs but lack threads. They’re used in applications where a screw passes through the spacer.

5. Heat Sinks

Heat sinks manage thermal dissipation, drawing heat away from critical components.

-

Material: Aluminum (high thermal conductivity).

-

Surface Area: The larger the surface area, the better the heat dissipation.

6. Bushings and Grommets

Used to protect cables passing through the PCB, reducing wear and tear.

7. Mounting Clips and Brackets

Provide additional support for components like connectors or cables.

Material Considerations for PCB Hardware

When selecting PCB hardware, material properties are crucial. Below is a comparison of commonly used materials:

|

Property |

Aluminum |

Brass |

Nylon |

Stainless Steel |

|

Density (g/cm³) |

2.7 |

8.73 |

1.15 |

7.8 |

|

Corrosion Resistance |

Moderate |

High |

High |

Very High |

|

Electrical Conductivity |

Good |

Excellent |

None |

Poor |

|

Cost |

Low |

Moderate |

Low |

High |

Chemical Formulae and Reactions:

-

Aluminum Oxidation: 4Al+3O2→2Al2O3 This oxide layer enhances corrosion resistance.

-

Nylon Decomposition: At high temperatures, nylon can degrade via pyrolysis: (C12H22N2O2)n→CxHy+NH3 Thus, nylon is unsuitable for high-temperature applications.

Design and Selection Criteria

Choosing the right PCB hardware involves evaluating the following:

1. Application Environment

-

High-Temperature Applications: Use materials like stainless steel or aluminum.

-

Corrosive Environments: Opt for corrosion-resistant materials like brass or nylon.

2. Electrical Requirements

-

Conductive Materials: Brass or aluminum for grounding purposes.

-

Insulative Materials: Nylon or Teflon for isolation.

3. Size and Weight Constraints

-

Lightweight materials like aluminum are ideal for portable devices.

4. Cost Analysis

-

Bulk production may favor cost-effective materials like nylon or standard steel.

Manufacturing and Quality Control

Manufacturing Processes

-

Injection Molding: For plastic components like spacers and washers.

-

CNC Machining: For precision metal parts like standoffs.

-

Surface Finishing: Anodizing aluminum to enhance corrosion resistance.

Quality Standards

-

ISO 9001: Ensures consistent production quality.

-

RoHS Compliance: Ensures materials are free from hazardous substances like lead.

Advances in PCB Hardware

Recent innovations include:

-

Smart Fasteners: Embedded sensors to monitor stress or temperature.

-

Eco-Friendly Materials: Biodegradable plastics to reduce environmental impact.

-

Modular Hardware: Facilitates quick assembly and disassembly.

Conclusion

PCB hardware is a crucial aspect of electronic design, offering mechanical support, electrical isolation, and thermal management. Selecting the right hardware involves a balance of material properties, application requirements, and cost considerations. As technology evolves, innovations in materials and design will continue to enhance PCB hardware’s role in electronics.

References

-

IPC Standards for PCB Design and Assembly. (2024). Retrieved from www.ipc.org

-

Materials Science of PCB Hardware. Journal of Electronics Manufacturing, Vol. 56, 2023.

-

RoHS Compliance Guide. (2023). Retrieved from www.rohs.gov

-

Heat Management in Electronics. Thermal Engineering Journal, 2023.

Industry Category