What Is PCBA Process during manufacturing of 5 Essential Factors?

By:PCBBUY 10/18/2021 10:39

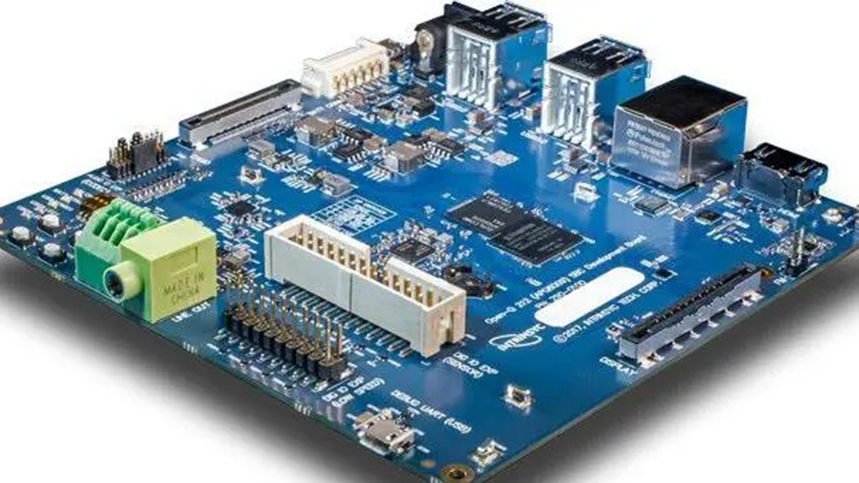

A circuit board prior to assembly of electronic components is known as PCB. Once electronic components are soldered, the board is called Printed Circuit Assembly (PCA) or Printed Circuit Board Assembly (PCBA) or PCB Assembly. Different Manual and Automatic PCB Assembly Tools are used in this process.

And if you are searching for more information about PCBA, you can check and read this passage to learn the professional knowledge. If you are interested in this topic, please pay attention to the content below for more.

1. What is the basic definition of PCBA?

PCBA is one electronic part that has assembled components(such as capacitance, resistance, IC, connector, etc.) on PCB, with SMT, DIP, and soldering assembly technology. All electronic devices have PCBA, and Electronic devices are everywhere. They range from smart phones to microwave oven and from laptops to cars. So, almost everyone is familiar with the PCBA.

2. What are the preparations before PCBA?

Following PCB Assembly Tools, electronics parts and consumables are needed for PCB assembly –

· Printed Circuit Board

· Basic Electronic components

· Soldering materials including solder wire, solder paste, solder bar, solder balls for BGA, solder performs (depending on the type of soldering to be done)

· Soldering flux

· Soldering equipment including soldering station, wave soldering machine, SMT equipment, and inspection and testing equipment etc.

Once all of the above equipment, electronic parts and all raw materials are arranged, it is time to start the printed circuit board assembly process.

3. What are the PCBA capabilities?

Many useful machines make the manufacturing process very straightforward and easy. Below are some remarkable machines:

· Machine for Solder Paste Printing: Manufacturers use this machine to apply the paste on the precise location of the circuit board. We have already talked about this machine in the previous section.

· Machine for Solder Paste Inspection: PCBA factory uses this machine to inspect circuit boards after applying solder paste. It tells the manufacturing team whether paste is at the precise location on the board or not.

· Glue Dispensing Machine: Makers use this machine to apply many dots of glue on the circuit boards before placing the components.

· Pick and Place Machine: After placing glue dots, companies use this machine to pick and place different components on the circuit board.

· Reflow Soldering Machine: It is another important machine for making a PCBA circuit board. The most important part of this machine is a conveyor belt. You have already learned about the conveyor belt in the previous section.

· Wave Soldering Machine: Manufacturers use this machine as an alternative option to the previous machine. When manufacturers need to pass circuit boards from the wave of molten solder instead of simple heaters, they utilize this machine.

4. What is the process of PCBA?

The process of PCBA processing is: solder paste stirring → solder paste printing → SPI → placement → Reflow soldering → AOI → Rework

Solder paste mixing

After the solder paste is taken out of the refrigerator and thawed, it is stirred by hand or machine to suit printing and soldering.

Solder paste printing

The solder paste is placed on the steel mesh, and the solder paste is printed on the PCB pad by a doctor blade.

SPI

SPI is a solder paste thickness detector that can detect the solder paste printing and control the solder paste printing effect.

Placement

The chip components are placed on the Feida, and the chip head is accurately placed on the PCB pad by identifying the components on the feeder.

Reflow soldering

The mounted PCB board is reflowed, and the paste-like solder paste is heated to a liquid after passing through the high temperature inside, and finally cooled and solidified to complete the soldering.

AOI

AOI is an automatic optical inspection, which can detect the welding effect of the PCB by scanning, and can detect the defects of the board.

5. What is the relationship of PCB and PCBA?

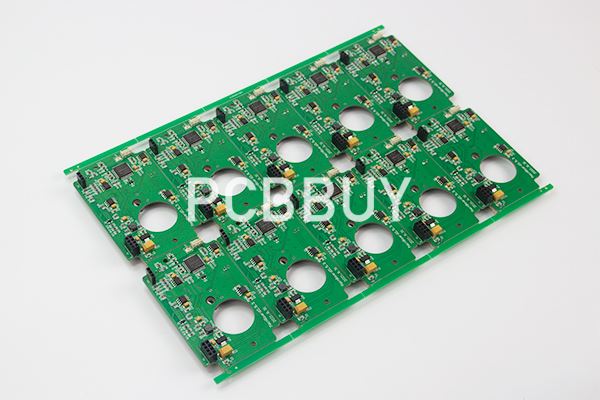

PCB and PCBA are the results of two different steps of the same overall process. A PCB is a blank circuit board with no electronic components attached, while a PCBA is a completed assembly that contains all of the components required for the board to function as needed for the desired application. A PCB is not yet functional, while a PCBA is ready to be used in an electronic device.

Manufacturing a blank board is a simpler process than producing a completed PCBA because of the various components and processes involved in PCB assembly. It also costs more to produce a PCBA than a blank PCB. However, both steps are necessary to create a completed board. You can not create a PCBA without a PCB. PCB manufacturing is the first step in the process, and PCBA manufacturing builds upon that first step.

Industry Category