What Is Power Pcb?-4 Types

By: 08/24/2023 11:41

Power supply circuit boards are a core component of electronic devices, responsible for converting AC power into the required DC power, as well as managing and protecting the power supply. With the rapid development of electronic technology, the design and manufacturing technology of power supply circuit boards are continuously advancing, becoming a crucial factor influencing electronic device performance and stability. This article aims to systematically study the design, manufacturing, optimization, and application prospects of power supply circuit boards, providing theoretical support and practical guidance for the development in related fields.

Design of Power Supply Circuit Boards

Power supply circuit boards are vital components of electronic devices, and their design plays a critical role in determining power performance and stability. The design process involves circuit design, component selection, routing design, and more. Depending on the device's requirements, suitable circuits need to be designed to achieve the desired power conversion and control functions. Circuit design must consider aspects such as power output, voltage levels, current magnitudes, and stability. Factors like electromagnetic interference, noise, and heat dissipation also need to be considered in the design to ensure stability and reliability.

Component selection is another important aspect of power supply circuit board design. Different components have varying performance and costs. Selecting appropriate components can enhance power performance and stability while reducing costs. When selecting components, specifications, parameters, prices, compatibility, and interchangeability need to be considered.

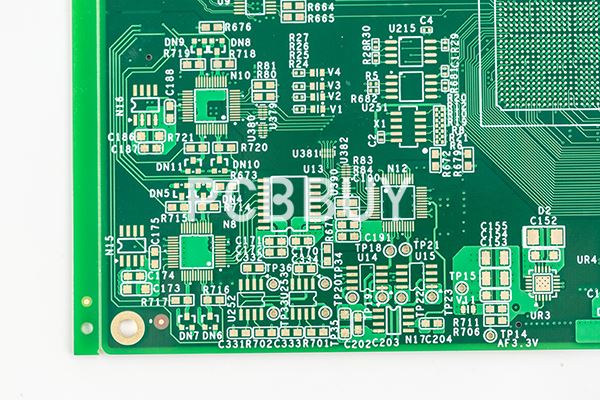

Routing design is crucial in power supply circuit board design. Proper routing design directly affects power performance and stability. It involves considerations like circuit layout, trace length, trace width, and spacing. Similar to circuit design, electromagnetic interference, noise, and heat dissipation should be considered in routing design to ensure stability and reliability.

Types of Power Supply Circuit Boards

There are several types of power supply circuit boards, including:

Single-Sided Boards: These have a single copper layer, and the circuitry can only be placed on one side.

Double-Sided Boards: These have two copper layers, allowing circuitry to be placed on both sides, connected through vias.

Multilayer Boards: These have three or more copper layers, allowing circuitry to be placed on multiple layers, connected through internal pathways.

Rigid-Flex Boards: Combining rigid and flexible PCBs, these allow bending where needed while maintaining circuit connections.

Materials for Power Supply Circuit Boards

The core material for power supply circuit boards is the substrate, commonly made from organic or inorganic materials. Organic materials typically include thermosetting resins or thermoplastic polyesters. Phenolic resin and epoxy resin are commonly used thermosetting resins, while polyimide and polytetrafluoroethylene are often used thermoplastics. These materials are used for both rigid and flexible PCBs, providing good electrical and mechanical properties.

In addition to the substrate, other materials such as copper foils, printing inks, solder masks, and chemical substances are used in the manufacture of power supply circuit boards. These materials provide conductivity, protection, and prevent oxidation, among other roles, which are crucial for manufacturing and performance.

Manufacturing of Power Supply Circuit Boards

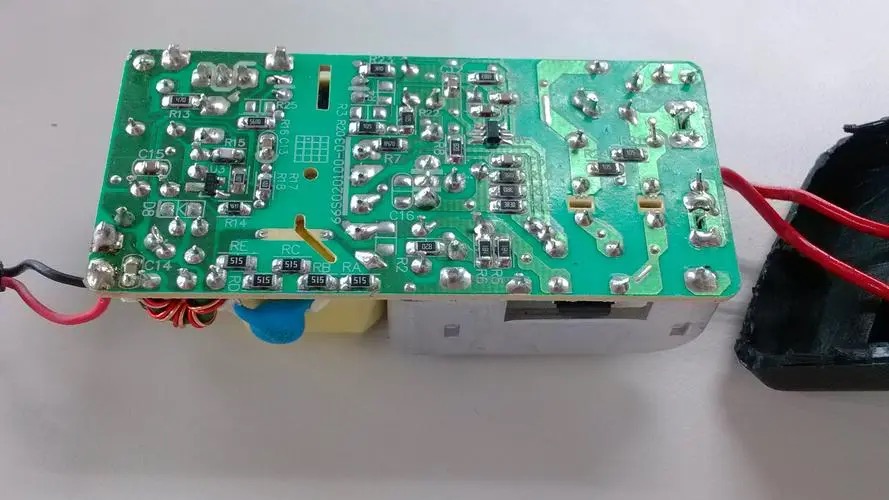

Manufacturing power supply circuit boards is an essential step in electronic device production, with the quality and performance directly influenced by the manufacturing process. The manufacturing process involves several stages, including PCB fabrication, component assembly, soldering, and more.

The PCB fabrication process is where the manufacturing begins. PCBs are typically manufactured using printed circuit board technology, including material selection, cleaning, printing, drying, and more. Precise and stable fabrication is necessary to ensure accuracy and maintainability.

Component assembly is a central part of manufacturing power supply circuit boards. During this process, components are installed and soldered onto the circuit board according to the circuit design. Component installation requires considering specifications, parameters, size, compatibility, and interchangeability. Soldering must ensure stability and reliability while avoiding issues like cold solder joints or bridging.

Lastly, testing the power supply circuit board is a crucial manufacturing step. Testing aims to check if the board functions correctly and to identify potential faults. Testing includes power tests, functionality tests, and withstand voltage tests, among others. Accurate and reliable testing helps identify and address problems promptly.

Optimization of Power Supply Circuit Boards

Optimizing power supply circuit boards is essential to enhance power performance, reduce energy consumption, and improve electronic device reliability and stability. Optimization involves various aspects, including circuit optimization, component optimization, heat dissipation design, and more.

Circuit optimization is a pivotal aspect of power supply circuit board optimization. It involves improving circuit diagrams, routing, and other aspects to enhance power performance and stability. Methods include adopting superior circuit topologies, optimizing component layouts, and reducing line losses. Circuit optimization can reduce noise, improve response characteristics, and enhance efficiency.

Component optimization is also crucial in power supply circuit board optimization. Component selection involves considering performance parameters, reliability, costs, and other factors. Additionally, reducing component numbers and types can minimize mutual interference, boosting stability and reliability.

Heat dissipation design is a key aspect of power supply circuit board optimization. Effective heat dissipation design ensures proper operation in high-temperature environments, enhancing reliability and stability. Common heat dissipation methods include adding heat sinks and employing heat pipes to lower temperatures and ensure stable operation.

Lastly, the application of intelligent optimization algorithms provides new means for power supply circuit board optimization. For example, genetic algorithms, particle swarm optimization algorithms, and other intelligent optimization methods can optimize power supply parameters to enhance performance and efficiency.

Application Prospects of Power Supply Circuit Boards

As a fundamental part of electronic devices, power supply circuit boards have a wide range of applications, spanning computing, communication, power, industrial control, and more. With technological advancements, their application prospects are expanding further.

Firstly, with the rapid development of the Internet of Things (IoT), power supply circuit boards will find broader applications in IoT devices. IoT devices require robust power management functions, and power supply circuit boards can efficiently accomplish power conversion and control tasks, ensuring stable operation of IoT devices.

Secondly, as new energy technologies continue to evolve, power supply circuit board applications in new energy fields such as solar and wind energy will expand. New energy devices require efficient power conversion and control systems, which power supply circuit boards can provide, ensuring reliable operation.

Furthermore, with the proliferation of electric vehicles (EVs), power supply circuit boards will play an increasingly crucial role in EVs. EVs demand efficient, high-power management systems, and power supply circuit boards can implement efficient energy conversion and control systems, supporting stable operation.

Additionally, the rapid development of artificial intelligence (AI) technology will see increased applications of power supply circuit boards in AI. AI devices require substantial computation and data processing, and power supply circuit boards can provide efficient and stable power management, supporting AI device operation.

Conclusion

Power supply circuit boards are integral components of electronic devices, and their design and optimization are vital for device stability and safety. With ongoing technological progress and expanding application domains, the study and application prospects of power supply circuit boards are promising for the future.

Industry Category