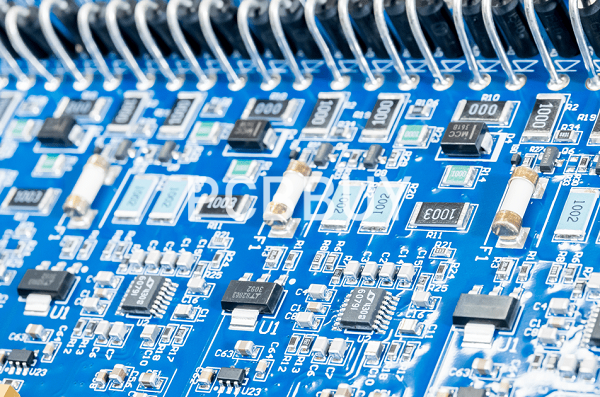

What Is Surface Mount Technology Used for PCB Assembly?

By:PCBBUY 06/23/2022 11:52

What separates surface mount from through-hole technology is that there is no need to drill holes in the circuit board to connect the tracks and the components. Establishing relationships through leads. The ingredients are in direct touch with the PADs of the circuit board And add solder paste to PAD with the help of stencil solder. There is also a pick and place machine responsible for placing the components on the solder paste set initially above the PAD. After setting these components, they have to be placed in a reflow oven or introduced in a vapor phase to be soldered permanently in the surface mount PCB assembly.

If you are searching for more information about surface mount technology in PCB manufacturing, please check and read the content below for more professional knowledge.

What are the preparations before SMT PCB assembly?

A few preparatory steps have to happen before real PCBA process even begins. This helps PCB manufacturers assess the functionality of a PCB design, and primarily includes a DFM check.

Most companies specializing in PCB assembly need the design file of the PCB to start out, along with any other design notes and specific requirements. This is so the PCB assembly company can check the PCB file for any issues that may affect the PCB's functionality or manufacturability. This is a design for manufacturability check, or DFM check, for short.

The DFM check looks at all the design specifications of a PCB. Specifically, this check looks for any missing, redundant or potentially problematic features. Any of these issues may severely and negatively influence the functionality of the final project. For example, one common PCB design flaw is leaving too little spacing between PCB components. This can result in shorts and other malfunctions.

What is SMT and its advantages?

Surface Mount Technology is a newer way of arranging components on printed circuit boards. For many years prior, electricians and engineers would use leads to fit circuit board components through holes. Careful preparation was necessary to ensure that all leads were formed in the right way to fit on various types of boards.

SMT assembly is a more efficient process where components are soldered directly onto the board. By eliminating the need for passing leads through PCBs, the process has become faster, more efficient, and cost-effective. SMT assembly also saves space, allowing more components to be housed on a smaller board. This is why many modern devices are smaller but pack lots of features.

SMT is a highly intricate process where each component is strategically positioned and mounted onto electrical boards for optimal functionality. This is one of the reasons why SMT and SMD overlap. Having an effective electrical device requires a combination of proper component selection and mounting strategies. During SMT, calculated amounts of solder paste are applied onto the board before a machine carefully mounts each component.

How to choose PCB SMT factory?

Choose the equipment

This is the first and most important thing to do when choosing a production facility. The factory must be located in an area with excellent communication systems. It is suggested to ask the factory owner why they chose that area. Is it close to the railway or highway? Is it near the airport? These are all good questions to ask when choosing a factory. If you are going to have your own transportation, it becomes less important if it is close to transportation lines, but if you are going to use public transport, this will become a priority.

Industry experience

Many factories will claim that they have been in the industry for a very long time, but this is not always true. If you are not careful, you may be cheated. Therefore, it is suggested that you should check the company’s records and find out how long they have been in business and whether or not they have a good reputation.

The following are some of the methods to check if a factory has a good reputation. First, it is suggested to ask around about this factory by talking with other suppliers or customers who may know about them. Second, if possible, you should go to the factory and talk with its employees; their attitude towards you will show their reputation. Third, you can visit some of their customers and ask them what they think of the factory; their answers will also help your decision.

Delivery Ability

The next important thing to do when choosing a factory is checking their delivery ability. If a factory cannot deliver on time, it may render your project useless. Therefore, it is very important to check the factory’s delivery ability before making a purchase.

How to decide which technology is best for design?

Manufacturing tests like PCB functional test the best time to decide between an SMT or PTH part is when you are choosing the components that you will use in your schematic. By incorporating these parts early in the design, you will make sure that the PCB Layout is created with the correct component package footprints. Here are some questions to consider when making your decision:

· Use: Will this component get “touched” much or be subjected to other stress?

· Power: Will this component be conducting a lot of power and heat?

· Performance: Which package style will give your circuit the best performance?

· Price: Is there a price benefit by choosing one package style over the other?

Availability: How quickly will the part be available for prototypes?

Industry Category