What Is Through-Hole of PCB?

By:PCBBUY 01/22/2025 17:26

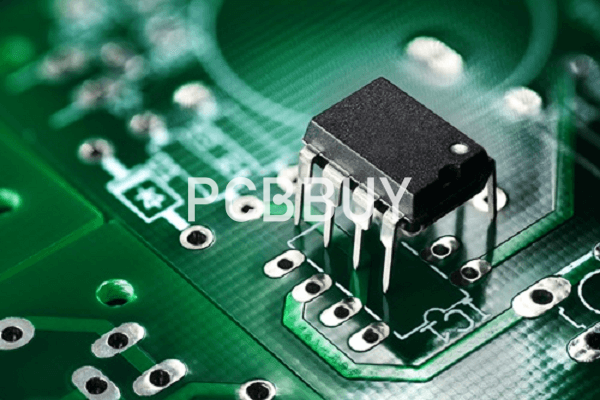

Printed Circuit Boards (PCBs) are fundamental components in modern electronics, providing the mechanical structure to support electronic components and the electrical interconnections between them. One of the critical features of PCBs is the through-hole, which plays an essential role in connecting different layers of the PCB and mounting components. This article provides a comprehensive overview of through-hole processing on PCBs, discussing the methods, materials, challenges, and best practices associated with this critical PCB feature.

How to Understanding Through-Hole Technology (THT)?

Through-hole technology (THT) refers to the process of drilling holes into a PCB and using them to mount and solder electronic components. These holes are called *vias*, and they are typically used for several purposes:

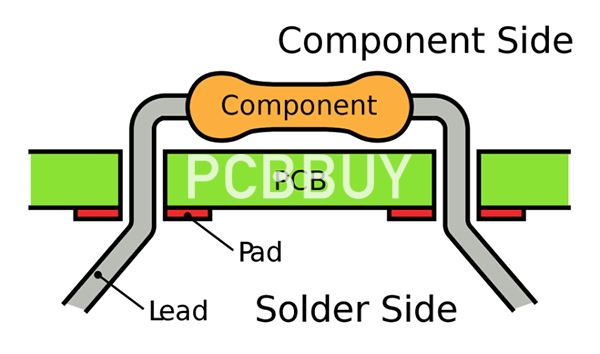

Component Mounting: Through-holes allow the leads of electronic components to pass through the board and be soldered on the other side, providing a strong mechanical bond and reliable electrical connection.

Electrical Connections Between Layers: In multilayer PCBs, through-holes serve as pathways that electrically connect different layers of the board. These inter-layer connections are vital for complex circuit designs.

What Are Types of Through-Holes?

Through-holes can be classified based on their function and location within the PCB:

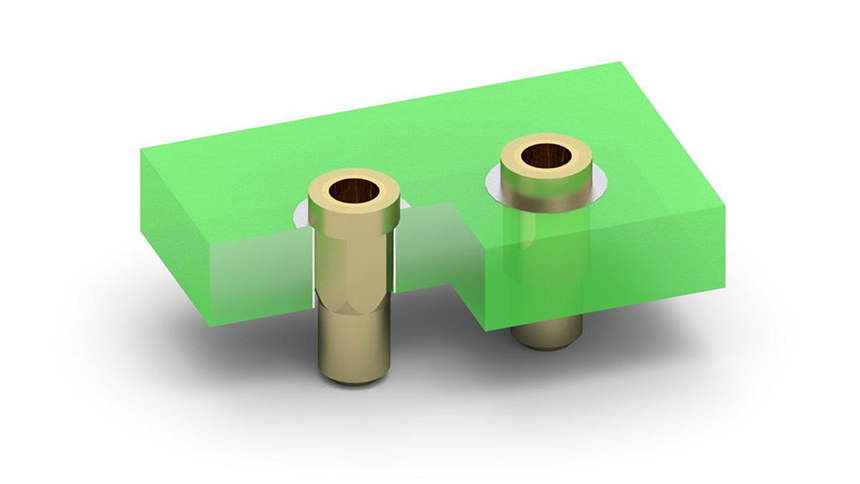

Plated Through-Hole (PTH): These holes are plated with a conductive material (usually copper) to create electrical connections between different layers of the PCB. PTH is commonly used for mounting components and interconnecting layers.

Non-Plated Through-Hole (NPTH): These holes are not plated with conductive material and are primarily used for mechanical purposes, such as mounting screws or aligning the PCB within a device.

Via Holes: Vias are a type of through-hole specifically used to connect different layers of a multilayer PCB. There are three main types:

Through Via: Connects all layers from the top to the bottom of the PCB.

Blind Via: Connects an outer layer to one or more inner layers but does not pass through the entire board.

Buried Via: Connects internal layers without reaching the outer layers.

What Are Materials Used in Through-Hole Plating?

The through-hole plating process involves the deposition of conductive materials to create an electrical path. Common materials used in this process include:

Copper: The primary material used due to its excellent conductivity and compatibility with PCB manufacturing processes.

Nickel and Gold: Often used as additional layers over copper to enhance corrosion resistance and solderability, particularly in high-reliability applications.

What Are Through-Hole Drilling Techniques?

Drilling through-holes is a crucial step in PCB manufacturing, requiring precision and accuracy. The primary techniques used for drilling include:

Mechanical Drilling: This traditional method uses high-speed drills with diamond-coated bits to create holes in the PCB. It is highly accurate but can be time-consuming for high-density designs.

Laser Drilling: A more advanced technique that uses a laser beam to ablate material and form holes. Laser drilling is faster and more suitable for creating smaller holes and vias, especially in high-density interconnect (HDI) PCBs.

What Is Through-Hole Plating Process?

The through-hole plating process involves several key steps:

Desmearing: After drilling, a desmearing process is applied to remove debris and smear (resin smear) from the holes to ensure a clean surface for plating.

Electroless Copper Deposition: An initial thin layer of copper is chemically deposited on the walls of the holes. This provides a conductive path for subsequent electroplating.

Electroplating: The PCB is then immersed in an electroplating bath, where additional copper is deposited to thicken the copper layer within the through-holes, enhancing electrical conductivity and reliability.

Post-Plating Processes: These may include annealing, etching, and applying additional coatings (e.g., tin, gold) to improve solderability and protect against oxidation.

What Are Design Considerations for Through-Hole Processing?

When designing PCBs with through-holes, several key factors must be considered:

Hole Size and Tolerance: The size of the hole must accommodate the component lead and allow for proper soldering. Common hole diameters range from 0.4mm to 1.0mm, with tolerance levels typically at ±0.1mm.

Aspect Ratio: This refers to the ratio of the PCB thickness to the hole diameter. High aspect ratios can lead to challenges in plating and reliability. A typical aspect ratio should be less than 10:1.

Pad and Annular Ring: The pad is the copper area around the hole on the surface of the PCB. The annular ring is the ring of copper left around the drilled hole after plating. Ensuring proper pad and annular ring dimensions is crucial for mechanical strength and electrical reliability.

Thermal Management: Through-holes can act as heat conductors, and their placement can affect the thermal performance of the PCB. Designers must consider heat dissipation requirements and may use thermal relief pads to control heat flow.

What Are Challenges in Through-Hole Processing?

Through-hole processing can present several challenges:

Misalignment: Drilling misalignment can lead to off-center holes, which may cause poor solder connections or break the conductive path. Precision drilling and proper alignment techniques are essential to minimize this issue.

Plating Voids: Incomplete plating or voids can occur within the through-hole, compromising electrical connectivity and reliability. Proper control of the plating process and thorough inspection are necessary to prevent voids.

Stress Cracking: Thermal and mechanical stresses can cause cracking in the plated through-hole walls, leading to intermittent or open circuits. Using appropriate materials and design techniques to reduce stress concentrations is crucial.

What Is Inspection and Testing?

To ensure the quality and reliability of through-hole processing, thorough inspection and testing are necessary:

Visual Inspection: Automated optical inspection (AOI) systems can detect surface defects, misalignment, and incomplete soldering.

X-Ray Inspection: This non-destructive testing method is used to inspect the internal structure of through-holes, detecting voids, cracks, and misalignments.

Electrical Testing: Continuity and insulation tests are performed to ensure that through-holes provide proper electrical connections and isolation as required.

What Are Advances in Through-Hole Technology?

Recent advancements in through-hole technology include:

Microvias: These are smaller diameter vias (<0.15mm) used in high-density PCB designs. Microvias enable more compact and efficient layouts, supporting the trend toward miniaturization.

Stacked and Staggered Vias: These advanced via structures offer higher routing density and more robust electrical connections, making them suitable for complex, multilayer PCBs used in advanced electronics.

Hybrid Vias: Combining traditional through-holes with microvias, hybrid vias provide a balance between mechanical strength and routing flexibility, ideal for high-performance applications.

What Are Best Practices for Through-Hole Processing?

To optimize through-hole processing and ensure the reliability of PCBs, consider the following best practices:

Optimize Drill Parameters: Proper drill speed, feed rate, and tool selection are critical to achieving clean, precise holes without damaging the PCB material.

Control Plating Thickness: Consistent plating thickness ensures reliable electrical connections and mechanical integrity. Regularly monitor and adjust the plating process to maintain uniform thickness.

Use High-Quality Materials: Selecting appropriate PCB materials, such as high-quality copper and reliable plating solutions, enhances the performance and durability of through-holes.

Implement Robust Design Rules: Establish and adhere to design rules that consider hole size, aspect ratio, pad size, and thermal management to prevent common through-hole issues.

Conduct Thorough Testing: Employ comprehensive inspection and testing methods, including AOI, X-ray, and electrical testing, to detect and address defects early in the manufacturing process.

Conclusion

Through-hole processing is a fundamental aspect of PCB manufacturing, enabling reliable component mounting and electrical interconnections. By understanding the different types of through-holes, materials used, drilling techniques, and plating processes, designers and manufacturers can optimize their PCB designs for performance and reliability. Advances in through-hole technology continue to push the boundaries of what is possible, supporting the development of more compact, efficient, and high-performance electronic devices.

As the electronics industry evolves, through-hole processing will remain a critical component of PCB manufacturing, requiring ongoing innovation and adherence to best practices to meet the demands of modern electronics.

References

1. **Coombs, C.F., Jr. (2001).** *Printed Circuits Handbook* (6th ed.). McGraw-Hill.

2. **Reed, D. (2017).** "Through-Hole Technology: A Key Component of Reliable PCB Design." *Journal of Electronics Manufacturing*, 34(2), 110-120.

3. **Smith, J. (2018).** "Advances in Through-Hole Plating for High-Density PCBs." *International Journal of Circuit Theory and Applications*, 46(5), 632-645.

4. **PCB Design and Layout Guidelines,** (2020). IPC-2221B Standard.

Industry Category