What Is a PCB Switch during PCB Manufacturing Process?

By:PCBBUY 12/13/2021 09:18

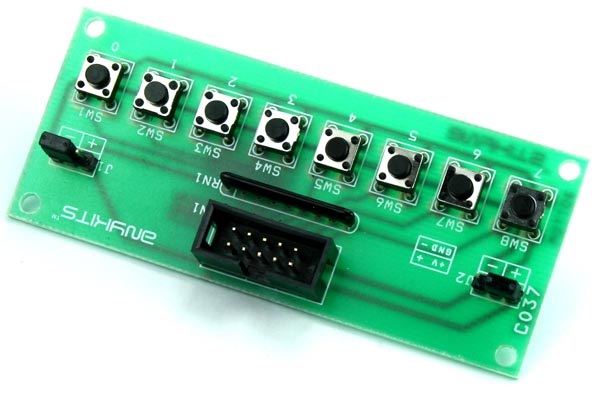

A PCB switch is a switch that is directly mounted onto a PCB (Printed Circuit Board). Surface mount PCB switches (SMD/SMT) are designed to sit flat, directly on top of a PCB. Through-hole or ‘thru-hole’ PCB switches are inserted into a drilled hole on the printed circuit boards and soldered to pads on the opposite side.

Do you know the details of PCB switch in manufacturing? If you are going to learn the details of PCB switch, please check and read the content below in this passage.

What is the basic definition of PCB switch?

A PCB switch is a type of electrical switch that’s characterized by the use of a printed circuit board. The term “PCB” even refers to “printed circuit board,” which is the primary feature driving this switch’s popularity. They are produced using a printed circuit board as the underlying circuitry powering the switch’s mechanism.

Different manufacturers design PCB switches in different ways. With that said, many PCB switches feature a layer of fabric that’s covered in copper. Known as the “copper-clad laminate later,” its conductive properties allow electricity to flow through it when the PCB switch is turned on and the circuit is complete.

What are the advantages of PCB switch?

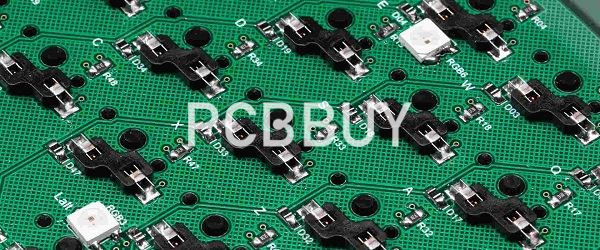

PCB switches support plating options as well. You can choose gold-plated PCB switches, for example, that feature a plated layer of gold. PCB switches even support backlighting, allowing for a deeper level of customization. The most common backlighting solutions used in PCB switches include light-emitting diodes (LEDs), light guides, electroluminescent (EL) and fiber optics.

Furthermore, PCB switches support multiple soldiering methods, including hard soldering as well as epoxy-based soldiering. While there are other types of electrical switches available, many businesses — and even some consumers for that matter — prefer PCB switches. For starters, PCB switches allow electricity to flow with less resistance. They are made of highly conductive materials, such as copper, to provide a lower level of electrical resistance.

If you want to buy a switch for your outdoor use, then a PCB switch will always prove an excellent option.

· Unlike some switches, a printed circuit board switch can withstand extreme and harsh conditions, including an outdoor setting.

· Printed circuit board switches support different plating options. For instance, you can decide to opt for a gold-plated switch.

· PCB switches support a backlight that allows for in-depth customization. In most instances, you will find LED (light-emitting diodes), electroluminescent, fiber optics, and light guides that prove typical backlighting solutions for PCB switches.

· Printed circuit board switches tend to support several soldering methods that include hard soldering and epoxy-based soldering.

What is DIP PCB switch?

In electronics, the acronym DIP when applied to switch types stands for ‘dual in-line package’. A dual in-line package switch, or DIP switch, is actually set of small manual electronic switches that are designed to be packaged with other circuits. The term DIP switch may refer either to an individual switch on a multi-switch unit, or to the entire unit as a whole.

In a nutshell, the role of DIP switches is to allow users to control the flow of electricity around a printed circuit board (PCB), expansion card or other electronics/computer peripheral, and therefore change the operating mode of a device.

When installed on a PCB alongside other electrical components, DIP switches offer the potential for the user to customise the behavior of the electronic device in question, enabling fuller control over the precise function the device will perform in a range of defined scenarios or applications. DIP switches are typically presented as a row of tiny toggle (on/off) switches, rather like a series of miniature standard light switches, mounted sequentially on a block of heat-resistant thermoplastic polymer.

As a complete component, a set of DIP switches is almost always very small, requiring some dexterity on the user’s part to toggle each switch between on and off positions. In day to day practice, this function is often performed with the point of a sharp pencil or a similar suitably shaped tool, as the individual switches themselves tend to be too small for comfortable finger operation.

How to plate mounting of PCB switch?

It entails the installation of switches atop a metal plate placed above the printed circuit board. The switches get soldered on the printed circuit board after getting placed on the metal plate. It will help reinforce and stabilize the keyboard besides making the keys feel heavier. However, such plates get used on larger keyboards in offering more support because of the larger size and the need to give the keyboard more stability. It also incorporates extra rigidity to your keyboard and secures it well.

A plate-mounted PCB differs from a PCB-mounted switch PCB as they don’t require the extra guiding pins that a PCB-mounted switch requires (3 or 5-pins). It is because the switch gets mounted on the plate instead of the printed circuit board. However, it helps if you remembered that it becomes incredibly difficult to remove the plate once you have soldered the switches.

Industry Category