What Is the Basic Information of BOM in PCB Design?

By:PCBBUY 12/14/2023 11:48

In SMT manufacturer, the bill of materials is the link for contact and communication with different people and departments. It is used in various departments and systems, and specific data is obtained from BOM. A bill of materials or product structure (sometimes bill of material, BOM or associated list) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts and the quantities of each needed to manufacture an end product.

In this passage, we are providing all the basic information about BOM in PCB Design. If you are going to learn more knowledge about BOM in PCB Design, please check and read the content below for more.

What Is the Basic Information of BOM in PCB Design?

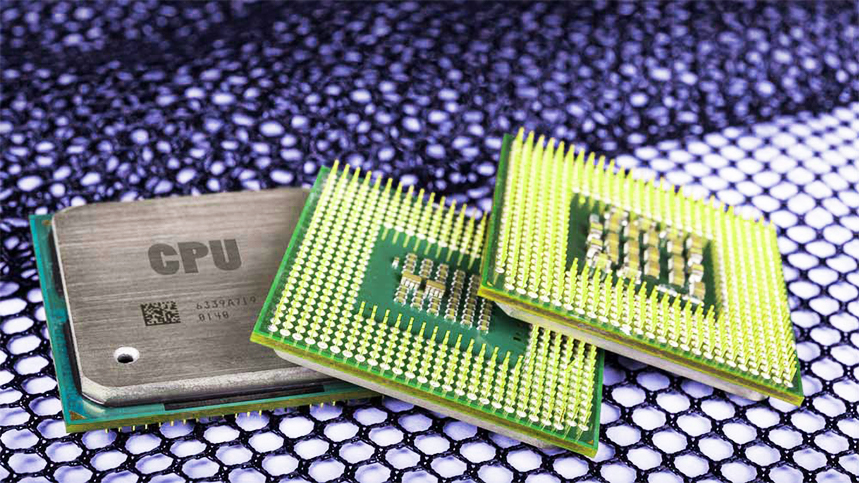

Electronic products are made up of numerous parts. This list of features needs to be created, checked, and even audited regularly if your organization is responsible for manufacturing and distributing any electronic product. It cannot be ignored. In a complete layperson's terms, the Bill of Materials (BOM) could be considered the "shopping list" of any given electronic product manufacturer.

The BOM should answer as many questions related to your electronic product as possible, from what they are, how they should assemble, to what kind of staff, and how much team is necessary for the assembly.

Let's compare the tech industry to the service industry. They essentially have their version of a BOM, which assists them when they need to order supplies or hire staff. It is no different when it comes to electronic product manufacturers. Although some of the items on their list may be different, it is still essential for them to create one.

What are the best practices of PCB BOM Inventory management?

The first step in establishing good practices for BOM inventory management in PCB CAD libraries is to develop a well-defined library process:

· Part requests: To build a new CAD part for PCB design should require a formalized request process. This request should be routed through component engineering to verify the application and availability of the requested part and confirm that the part conforms to company standards and policies.

· Manufacturing specifications: The parts’ datasheets should be kept on file within the design department and preferably within a product data management (PDM) system for access throughout design and manufacturing. This data will be used for the construction and the validation of the completed CAD models.

· Verification: The new part needs to be verified that it has been built correctly and satisfies the needs of all the key stakeholders (design, manufacturing, etc.). The verification sign-off should also be kept on file with the part request.

· Database updates: Once completed, the part needs to be installed in the library, and new part notifications published to the design team.

The next step of inventory management for PCB design teams is to establish the processes and procedures mentioned above for part updates and verifications in new designs. CAD library parts need to be confirmed in new designs as being the latest versions and available from the company’s supply chain. There also needs to be procedures in place to run the automated part checks through the CAD system on completed designs before they are sent out for manufacturing.

Why is BOM important?

Anything that involves electronic products requires a lot of organization and operations when it comes to any materials. The purpose of a BOM is to make sure that everything involved in an electronic product project is operating smoothly. When this process is not organized correctly, a lot of unsavory things can happen.

Costs

The creation of a proper BOM can reduce the costs involved in a project. Because there are many materials necessary when it comes to a project, much money goes into them. If a BOM is accurate and organized correctly, it can save a lot of money. One of the worst things that any manufacturer can do is rush to create a BOM. If the logistics list is in a hurry, two things can happen.

First, insufficient material is ordered, and it will cost more money to get more materials contained, especially if time is of the essence, and you need the materials delivered quickly. The second thing that can happen is that you can get too many materials, it also means spending too much money. While it is true that you will possibly have surplus materials for the next project, the amount paid exceeds the necessary amount.

Staffing and Personnel

One thing related to cost is employees and people. Having staff to work on a project is something that should be directly determined by what is contained in the BOM. If you don't take the BOM seriously, it can affect employees to hire too many people. The staff members will not be compensated the way they like or also employ a few people, and their production will suffer from being overwhelmed and overworked.

Industry Category