What Is the Function of UL Certification for PCB?

By:PCBBUY 12/07/2023 15:54

UL is the only organization that publishes PCB safety standards. UL certification can demonstrate the PCB products have been passed the product safety benchmark. And the UL recognized PCBs could be used globally.

Do you know the basic information of UL certification for PCB? If you are looking for more professional knowledge of UL certification for PCB, please check and read the content below.

Why UL certification is important?

The Underwriters Laboratory (UL) was founded in 1894 by William Henry Merrill, an American electrical engineer. UL is an independent, international organization that tests products, certifies manufacturers and documents safety standards for a diverse range of industries and applications.

It is well known that UL recognized PCB components and materials had passed the industry' s most stringent safety tests and follow-up program. With UL certification on the PCBs, PCB manufacturers can assure customers that the boards they get a match or exceed industry standards for preventing the electric shock or fire. It has been certified for safe use and follows specific standards and guidelines during development and construction.

Why Should You Care About UL?

Many end product standards now require their PCBs to be built with UL safety standards in mind. The following product categories are just a sample of the applications that UL standards cover:

· IEC 60065: Audio and Video Equipment

· IEC 60960: Information Technology Equipment

· IEC 60601: Medical Equipment

· IEC 61010: Equipment for Laboratory Use

· UL 508: Industrial Control Equipment

All of the applications above must be certified with a UL mark following three standards, UL 796, UL 746, and UL 94. These are broken down into specific sub-categories, which includes:

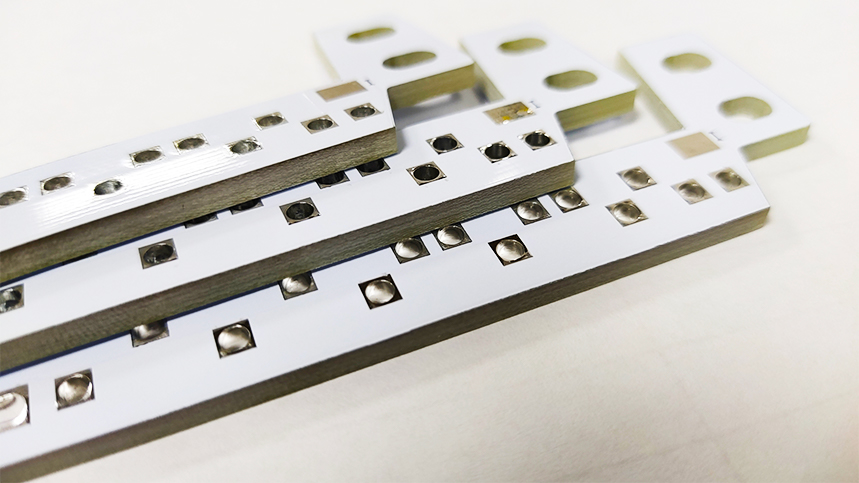

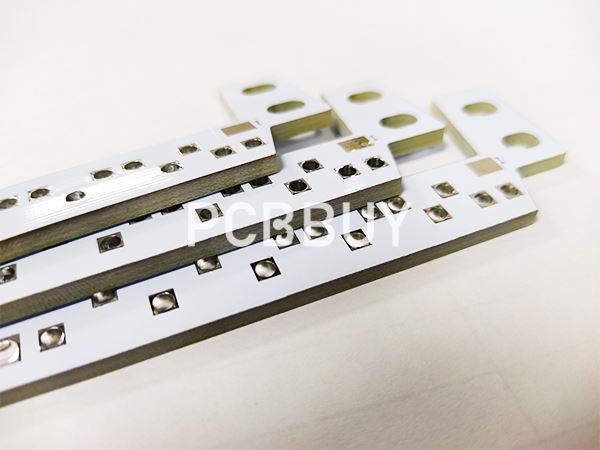

PCB Standard UL 796: This covers printed wiring boards (PWBs) guidelines for standard rigid, metal-based, and high-density interconnect PCBs.

PCB Standard UL 796F: This standard evolved to cover flexible material electronics including flex and rigid-flex PCBs.

PCB Standard UL 746E: This covers all industrial laminates and materials used in the PCB manufacturing process.

PCB Standard UL 746F: This covers all flexible dielectric film materials used in the PCB manufacturing process.

UL 94: This covers all flammability requirements for plastics and PCBs.

What Is the Function of UL Certification for PCB?

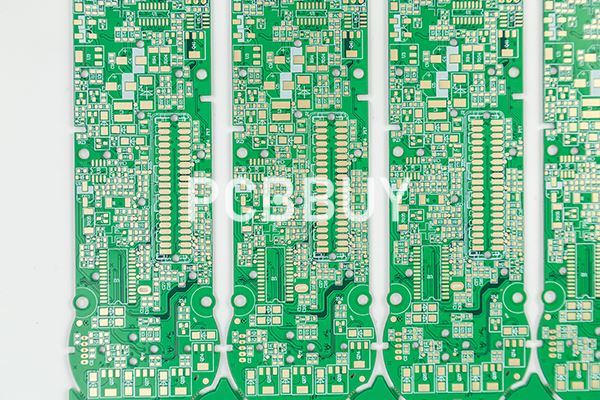

PCBs are key components of any electronic product. Any error in the design or assembly of the PCB can lead to product failure.

Electrical engineers are under increasing pressure to design smaller, flexible and more efficient PCBs to meet consumer demand for wearables, smartphones, 5G and Internet of Things (IoT) devices.

That type of pressure, coupled with stringent go-to-market deadlines, can lead to errors in design, easily damaging your product’s reputation. Fortunately, we can help you mitigate the risk of that happening.

We have been advancing safety science in support of PCB conformance assessments for more than 50 years. We can help increase consumer confidence in your products by demonstrating that your PCB is compliant to regulatory safety requirements and has been tested to the highest set of reliability and performance standards.

Our full range of PCB testing and certification services tests to UL Standards and many other international, national andregional requirements, including ASTM, IPC and International Electrotechnical Commission (IEC). Our testing services include:

Getting Your PCB Certified

The parameters for your PCB certification will be determined by the application of the board in the end product it is designed for. As we mentioned earlier, certain industries such as medical equipment have specific standards that must be met and certified in order for your board to be used. The parameters include the following:

· Specific flame rating

· Maximum operating temperature (MOT)

· Direct support requirements (DSR) compliance

· Minimum comparative tracking index (CTI) rating

If this is information new to you or you’re having trouble deciphering the applicability of various standards, help is available. Underwriters Laboratory has an engineering staff that can help you to determine what parameters you need to design for in your PCB.

Another source of assistance is your contract manufacturer (CM). They can help you determine which parameters you need certification for. They can also support you throughout the process of getting your boards set up and sent out for testing and certification.

Industry Category