What PCB solder mask process

By:PCBBUY 12/15/2023 09:09

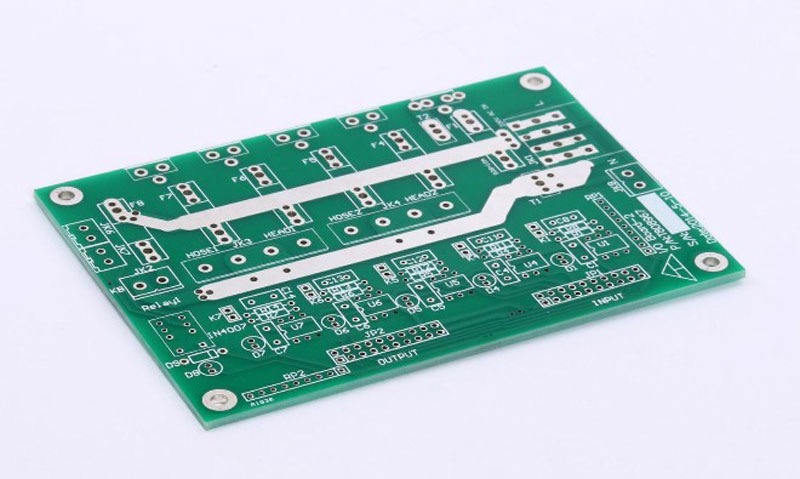

The solder mask process is a crucial step in the manufacturing of circuit boards, involving the protection and insulation of the traces and pads on the board. Here is a detailed explanation of the application of the solder mask process in circuit board manufacturing:

I. Importance of Solder Mask Process

In circuit board manufacturing, the solder mask process prevents oxidation, contamination, or damage to pads and traces during the soldering process. It shields the pads and traces from external environmental factors, thereby enhancing soldering quality and reliability.

II. Types of Solder Mask Process

-

Screen Printing Solder Mask: This method involves using a screen printing machine to apply solder mask ink onto the circuit board, creating the solder mask layer. It's suitable for medium to small-sized boards, offering advantages like cost-effectiveness and high efficiency.

-

Spray Coating Solder Mask: This technique utilizes spray equipment to coat solder mask ink onto the circuit board, forming the solder mask layer. It's applicable for larger circuit boards, providing advantages such as uniform coating and adjustable thickness.

-

Thermal Transfer Solder Mask: Using a thermal transfer machine, a heat-sensitive solder mask film is heated and transferred onto the circuit board, creating the solder mask layer. This method is suitable for miniaturized, high-precision boards, offering high resolution and heat resistance.

-

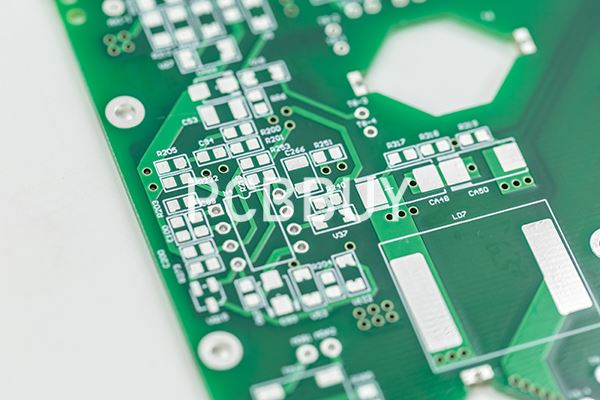

III. Solder Mask Process Workflow

Prepare the Substrate: Clean the circuit board to remove surface stains and oxides. Apply Priming Coating: Coat the substrate with a primer to enhance corrosion resistance and adhesion. Apply Solder Mask Ink: Use screen printing, spray equipment, or thermal transfer machines to apply solder mask ink onto the substrate, forming the solder mask layer. Cure the Solder Mask Layer: Cure the printed substrate to ensure a tight bond between the solder mask layer and the substrate. Inspect and Rectify: Inspect and rectify the cured board to ensure the integrity and quality of the solder mask layer.

IV. Considerations for Solder Mask Process

Select Suitable Solder Mask Ink: Choose appropriate solder mask ink based on board requirements and manufacturing processes to ensure performance and reliability. Control Thickness and Uniformity: Maintain control over solder mask ink thickness and uniformity during printing to prevent issues like missed printing or ghosting. Monitor Curing Temperature and Time: Control temperature and time during curing to avoid under-curing or over-curing issues.

Enhance Quality Inspection and Control: Strengthen quality inspection and control during production to ensure each process meets requirements.

Enhance Quality Inspection and Control: Strengthen quality inspection and control during production to ensure each process meets requirements.

In conclusion, the solder mask process is a vital aspect of circuit board manufacturing, safeguarding the traces and pads on the board. By selecting suitable solder mask ink, controlling ink thickness and uniformity, monitoring curing temperature and time, and enhancing quality inspection and control measures, the quality and reliability of the solder mask process can be ensured, thereby improving soldering quality and reliability of circuit boards.

Industry Category