What are different types of materials in PCB Manufacturing Process?

By:PCBBUY 01/17/2022 09:53

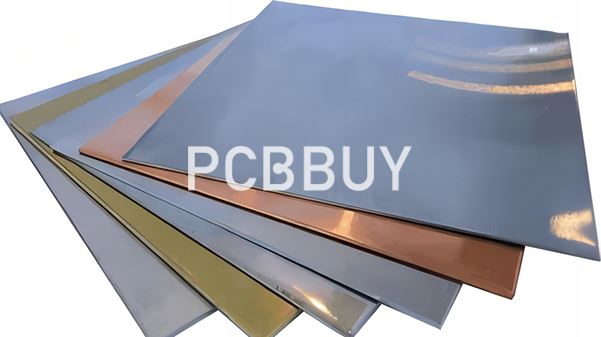

PCB material could be classified in several ways:

By Component location: single-sided, double-sided and embedded

By Stack-up: single layer and multi-layer

By Design: module-based, custom and special

By Bendability: rigid, flex and rigid-flex

By Strength: electrically strong and mechanically strong

By Electrical functionality: high frequency, high power, high density and microwave

By The board types can be used to select the circuit board material best suited for the design.

Single-sided PCBs include only one layer of a substrate, coated with a thin layer of copper. A protecting solder mask is laid down onto the copper layer. The silkscreen coat may be applied to the top to mark the elements of the board.

A double-sided PCB’s substrate includes metal conductive layers and elements attached to both sides (top and bottom).

Multi-layer PCBs enlarge the density and complexity of PCB designs by adding extra layers beyond the layers seen in the configuration of double-sided PCBs. These allow for extremely thick and highly-compound designs. Extra layers used are power planes that provide the supply to the circuit with power and decrease the levels of electromagnetic interference (EMI).

What are the special materials PCB material properties?

Rather than the aforementioned materials, we also utilize several special materials to assemble high frequency circuit boards. Here are some typical materials that we use for such circuits:

Rogers Corporation: These materials are FR-4 compatible, and are engineered for your exact performance requirements. These materials provide excellent results owing to their superior mechanical properties such as low dielectric loss, low signal loss, high thermal conductivity, and controlled impedance.

Arlon: These high performance laminates with specialized electrical, thermal, mechanical, or other performance characteristic are largely used in wireless communications infrastructure, military and commercial avionics, and semiconductor test and measurement equipment.

High Tg: This refers to high glass transition temperature. We employ these materials for PCBs used in critical and demanding applications including printed circuit boards exposed to high thermal loads. The material offers excellent performance at high temperatures, and exhibits good delamination property.

What are the properties of PCB substrate?

This material allows a minimum amount of electricity from the circuit. Because there exists an insulating layer between two conducting layers. For example, FR-4 is the most common sort of dielectric substantial. You must consider its properties before choosing it for your circuit board.

Here are the 4 most important properties of dielectric material:

Thermal Properties

Let’s consider the thermal properties of the substrate material:

A temperature range in which a glassy or rigid state of the PCB substrate becomes a softened or deformable state. The properties of the material return its original states after cooling down. You can express this temperature range in the Tg unit. And, you need to measure this temperature in degrees Celsius.

Electrical properties

Relative Permittivity of Dielectric Constant (Dk or Er)

It is very important to consider the dielectric constant of material for checking impedance considerations and signal integrity. Both are remarkable factors of high-frequency electrical performance. The range of Er is between 2.5 and 4.5 in most PCB substrate material.

Chemical Properties

Flammability Specs – UL94

It is a plastics flammability standard for classifying plastic from the lowest flame-retardant to the highest one. So it is very helpful for plastic material appliances testing. Underwriters Laboratories (UL) defines this standard. Here are some essential requirements of this standard:

What is future of PCB materials?

While minor changes in the ink used for silkscreen or the materials in your soldermask aren’t likely to make any headlines, the bulk of innovation effort seems to be focused on improving the CCL. The need for smaller, lighter boards for applications such as mobile devices has increased the demand for multilayer architectures which can pack more functionality into a smaller form factor.

Enhanced epoxy systems such as Getek, Megtron, 4000-13 and FR-408, which cite better performance than FR-4 with reduced Dk values and loss tangents. High performance materials such as A-PPE by Asahi Glass, Nelco 600-21 Si, and Rogers 4350, which offer significant improvements in lower Dk, better impedance control, and reduced jitter.

Industry Category