What are the considerations of making FPGA PCB?

By:PCBBUY 08/16/2023 13:55

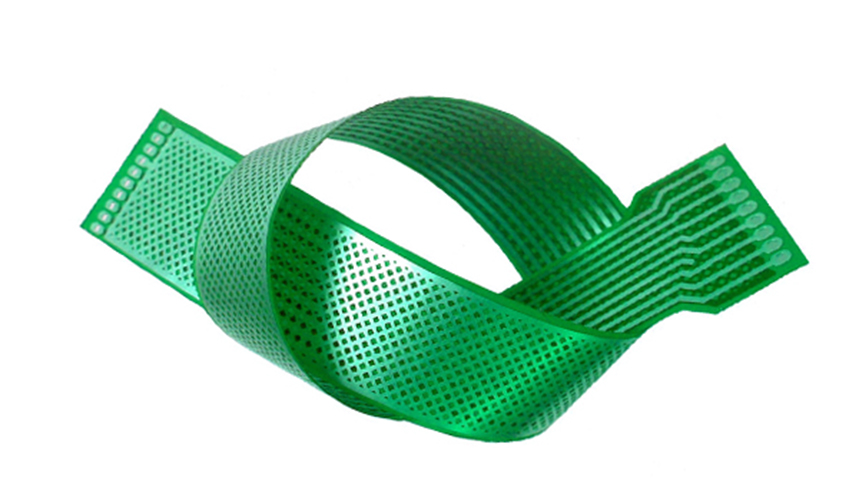

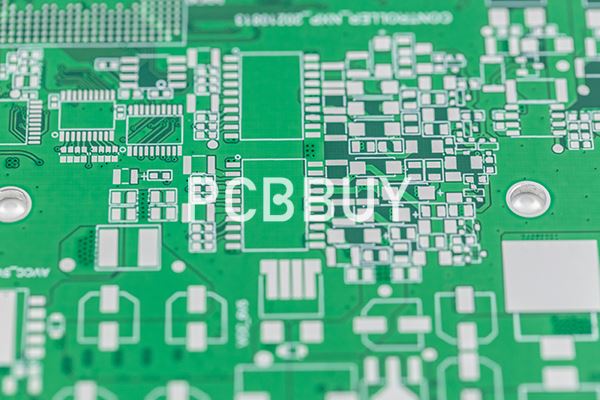

When designing a Printed Circuit Board (PCB) for Field-Programmable Gate Arrays (FPGA), several common challenges arise compared to standard PCBs due to the high-speed, high-density, and complex power requirements of FPGAs.

In this passage, we will tell you everything about the FPGA PCB in design process. If you are searching for more professional knowledge, please check and read the content below in this passage.

Programming Principle

Core Component 1: Programmable Logic Blocks

FPGA is composed of an array of programmable logic blocks, which are the basic functional units. They can be configured to implement both simple logic gates (such as XOR, AND) and complex logical functions.

Core Component 2: Reconfigurable Interconnects

The logic blocks are connected through a hierarchical reconfigurable interconnect structure. This structure acts as "programmable wires", enabling flexible connection between different logic blocks to form a complete circuit.

Auxiliary Component: Built-in Memory Elements

Most FPGA logic blocks integrate memory elements, such as flip-flops or complete memory blocks, which support data storage and sequential logic operations to enrich functional capabilities.

What are the considerations of making FPGA PCB?

1. Custom FPGA boards are suitable for projects with short lifecycle, high production volume, or strict small form factor requirements; COTS boards with add-ons (PMOD/FMC) are preferred for projects without such strict demands.

2. If the project life cycle exceeds the product lifetime of a DDR memory chip (a couple of years), then designing a custom FMC daughterboard may be a better alternative.

3. Cost is a factor in this decision. Most COTS FPGA boards are somewhat general-purpose, designed for maximum flexibility. If you're making a high-volume, cost-sensitive product, then it is probably worthwhile to make a custom design; but for low-volume you are probably better off concentrating on making a daughtercard.

4. Regardless of which approach you choose, there are certain interfaces that require clear, master documentation: at the interface between the FPGA toplevel I/O pins and the rest of the board, and at the connector interface between boards. These are places where pin locations, internal net names, and external net names sometimes get mismatched and swapped. A table is sufficient documentation; be sure to keep this interface table versioned and under source control. Before sending PCB files to fabrication, print out a copy of this interface table, a copy of the schematic, and a copy of the FPGA pin/pad report. Drag a highlighter across the papers to check off each signal connects where it should.

5. For connectors, I've learned the hard way to provide a mechanical "system drawing" that shows both boards and mating connectors together on a single, dimensioned drawing. I first got burned by a VME connector system where pin "A1" on one connector did not map to pin "A1" on the other connector. I've also seen designers forget that a pair of right-angle connectors results in a mirror image connection (90 degrees + 90 degrees = 180 degrees). This was a problem when I was responsible for the motherboard and several other project managers were responsible for various daughter boards.

Then why FPGA is reprogrammable?

The FPGAs can be reprogrammed for the implementation of a different logic function. It allows reconfigurable computing which is flexible. The FPGAs have the ability to start the development of system software along with the hardware, which makes them suitable for use in embedded systems development.

The concurrent development of hardware and software enables the simulations of system performance at a very early phase. It allows multiple system partitioning trials and iterations before finalizing the final system architecture.

What are the tips of FPGA design?

Intelligent design of the FPGA interface is an imperative when using FPGA devices to meet leading-edge system interface requirements such as DDR3. An FPGA interface design without PCB process integration or PCB routing consideration can lead to increased PCB costs and extended design times. The key, as this article demonstrates, is to consider connectivity as the foundation for a FPGA/PCB co-design process and the critical elements that are required for an effective implementation. Connectivity in this context is bidirectional movement of FPGA interface information between the FPGA and PCB domains.

Implementing an effective process-connectivity foundation enables the FPGA to be quickly incorporated into the PCB design. An important derivative of a connectivity solution is the repeatable creation of an FPGA interface definition that is optimized for both the FPGA and PCB. The results of this connectivity foundation are lower development costs and improved PCB quality.

FPGA proliferation

FPGA devices are ubiquitous in new product designs with approximately 100,000 design starts each year. No one argues that there are many benefits offered by FPGA technology. The industry leaders, Xilinx and Altera, both had sales in excess of $1 billion in 2007, with Xilinx approaching $2B.

There is a constant stream of new product offerings from the industry leaders that include Xilinx Virtex-5 FXT (high performance processing and I/O) and Virtex-4QV (space applications), Altera's Stratix IV (high density with 13.3 million gates), and Actel’s IGLOO (low power). The diversity of offerings should be a system designer's dream.

The FPGA design process is well-defined with a suite of FPGA vendor-provided tools to support it, which includes Xilinx's ISE, Altera's Quartus II, and Actel's Libero IDE. As each new generation of FPGA is delivered, so are the tools that see constant investment.

Industry Category