What is BOM in PCB Design to Improve PCB Manufacturing?

By:PCBBUY 09/24/2021 09:02

In the case of a PCB design, the bill of materials is a list of all the needed parts in the manufacturing process to build that specific printed circuit board. As each part is instantiated in the design, the part information is pulled along with it from the BOM.

The Bill of Materials (BOM) could be considered the "shopping list" of any given electronic product manufacturer in a complete layperson's terms. It should contain everything necessary to make sure that you get the parts you need for your product.

In this passage, we will focus on the BOM in PCB design and the effects to improve the PCB manufacturing. If you are interested in the BOM in PCB design, please check and read the content below for more information.

What is the 4 parts of BOM?

There can be many types of information in a PCB BOM, but the parts must have a core set of elements to start with. Here is a list of some of the more core elements that you will see in a PCB BOM:

· Comment: Each part type on the Printed Circuit Board needs to have a unique identifier, or part number, listed as a comment in the bill of materials. Typically a company designated part number is used as the comment, but this is not a requirement. Vendor component part numbers or other designations can be used as instead. An example of a comment could be the company part number “27-0477-03”.

· Description: This is a basic description of the part. In the case of the comment 27-0477-03 listed above, the description could be “CAP 10uF 20% 6.3V”.

· Designator: Each of the individual components on the board will have its own unique reference designator. In the case of the 10uF capacitor, it could be “C27”.

· Footprint: This is the name of the physical CAD footprint used by the part. For instance, C27 could be using a CAD footprint named “CAP-1206”.

Why to create BOM for PCB?

We now have a basic idea about what BOM is for PCBs. Let’s have a look at the main purpose of creating it. See our preferred BOM format.

All the components under a single roof

During the PCB assembly process, a BOM provides information about the components under a single roof such as their quantity, reference designators, footprints, etc. Designers will save lots of time and effort during PCB design by preparing a bill of materials with all the updated parts list. If the BOM is properly updated, then there will not be any chances of redesign during the later stages. Hence, an updated BOM saves time and effort.

Cost estimation

As explained earlier, a bill of materials is a file that has all the components required for assembling a circuit board. Cost estimation is a major decision when it comes to PCB projects. When the designers are in the initial stages of figuring out how many boards they need and the parts required for those boards, a BOM list can be really helpful.

Staffing and Personnel

One thing related to cost is employees and people. Having staff work on a project should be directly determined by what is contained in the BOM. If you don't take the BOM seriously, it can affect employees to hire too many people. The staff members will not be compensated the way they like or employ a few people, and their production will suffer from being overwhelmed and overworked.

How to create BOM for PCB step by step?

Regardless of the particular tool used, the creation of a BOM is divided into the following common steps:

· Creation of the initial version of the document, indicating on top the project name and any other useful information that allows immediate identification;

· Document organization, which identifies the users who can access it and their access rights (reading, writing, creation, cancellation, etc.). It is also necessary to activate the change tracking system and set up the physical repository (with backup functionality) that will host the file;

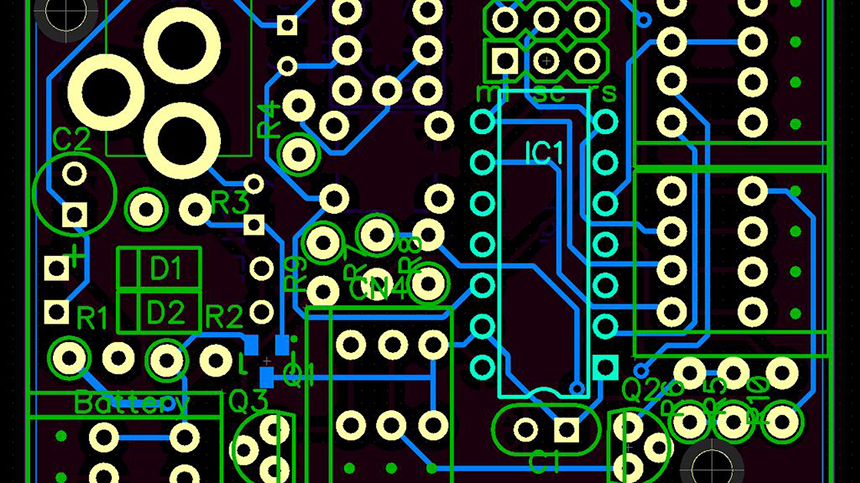

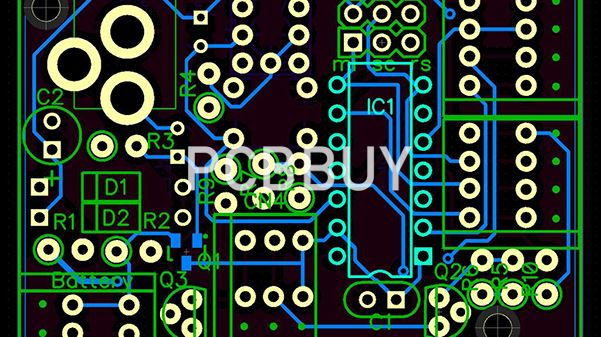

· Columns definition: each column of the spreadsheet must show on top the name that identifies the category, such as: name of the part, quantity, manufacturer, code, description and more (see Figure 1);

· Rows filling: for each element belonging to the BOM, a row must be added and properly filled. Since this information is crucial for the success of the project, the information entered must be accurate and consistent with the Gerber files of the PCB;

· Keep the BOM updated: once created, the file must be kept up to date, tracking every revision produced.

What are the useful tips for a successful BOM?

· Be as detailed as possible. There’s nothing to be gained by skimping on the details in your BOM. This one document alone needs to communicate exactly what parts your design is made from, so someone reading it can put the pieces together to understand your intent better.

· Know that your components are available. There’s nothing worse than slapping a part number down on your BOM that you know was available at one time but is no longer manufactured. To avoid this, be sure to confirm that the part numbers you enter are available. Otherwise, you might find yourself reworking your design to replace an obsolete or unavailable component.

· Keep track of your changes. Whether you’re the only person that will see your BOM or you hand it off to your manufacturer, we always recommend keeping track of every change you make. Part availability can change at a moment’s notice, and the parts you needed yesterday might be different today. Create BOM files with specific naming conventions that include a date, so you know which file is the most accurate and up to date.

Industry Category