What is CAF PCB during Manufacturing with 7 Effective Tips?

By:PCBBUY 08/08/2022 15:03

In this passage, we are going to learn more information about CAF PCB during manufacturing?

Please check and read the content below in this article for more professional knowledge.

How to identify the CAF PCB during manufacturing?

Identifying CAF once it occurs is challenging, making it difficult to inspect and study. CAF often occurs in layers buried within PCBs. It also can appear alongside other contributing failure factors, making it hard to realize when CAF is a solely-responsible failure mode.

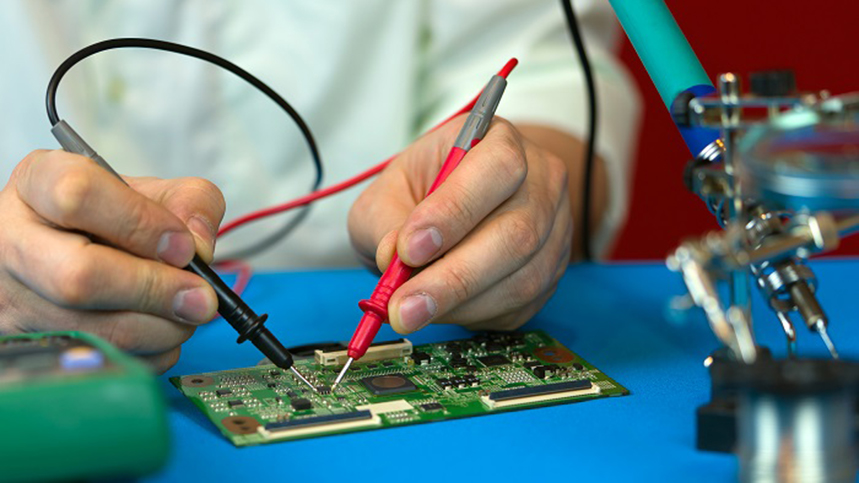

You can, however, use various advanced testing methods to check for and characterize CAF formation and failure. These tests include IPC-standard electrical methods known as Surface Insulation Resistance (SIR) tests, which include:

IPC Electrochemical Migration Testing: An IPC standard test to measure the resistance to the flow of current across the surface of a PCB substrate.

Temperature-Humidity-Bias (T-H-B) Testing: A SIR test that takes into account the processing temperature, relative and aging humidity and voltage bias.

You can also use various methods to image CAF formation on a PCB. These techniques include:

· Scanning Electron Microscopy (SEM): This method involves the use of a primary electron beam gun that sends electrons toward the positively charged anode in a vacuum through electromagnetic lenses. You can operate this device in either secondary electron (SE) mode — which is ideal for surface-topography imaging — or backscattered electron (BSE) mode, which allows for atomic number contrast.

· Energy Dispersive Spectroscopy (EDS): This incident electron beam can be used to identify elements such as copper, chlorine and bromine.

· Focused Ion Beam (FIB): With this technique, you can magnify a surface at high resolution and then make a thin cross section to obtain a 3-D image.

· Transmission Electron Microscopy (TEM): This system, which works similar to a light microscope, can identify material phases and determine the crystallographic structure.

· X-Ray Photoelectron Spectroscopy (XPS): Sometimes referred to as electron spectroscopy for chemical analysis (ESCA), this method is a surface-analysis technique that can identify chemical compounds.

· Fourier Transform Infrared Spectroscopy (FTIR): This technique analyzes organic constituents and creates a spectrum of intensity and wavelength readings.

· Ion Chromatography: This process, which may be either anion or cation-exchange chromatography, separates ions and polar molecules.

What are the reality problems of CAF PCB during manufacturing?

There are many different measures you can take to minimize the risk of CAF failure. Researching into ways to avoid this problem is ongoing, but avoiding the conditions enabling CAF formation will help prevent it. Here are some of the factors to consider:

Moisture and Humidity

Because it requires an electrolyte, higher water content increases the chance of CAF failure. Increased humidity leads to higher moisture content, which decreases CAF performance.

Processes That Lead to Acid Contamination

Processes used during fabrication can introduce acid contaminations, which increases the likelihood of CAF formation. The use of some soldering fluxes and the introduction of acid residues during the plating process are examples of this.

Bias and Voltage

Since bias voltage is the force that drives the reaction, a high-voltage bias will significantly lower the chances of CAF formation. Higher voltages decrease CAF performance as well.

Pre-Existing Defects

Pre-existing defects such as fracturing, voids, wicking, contamination and misregistration can also create pathways for problematic filaments. You need to be careful when drilling holes so as not to cause damage to the board. Such damage can create these pathways by causing cracks, wicking and other defects. Drill speed, feed rate and other factors influence how likely these issues are to occur. Partial defects such as incomplete bridging between features can contribute as well.

High temperatures like those from environmental temperature, repetitive thermal cycling and reflow with a high peak temperature create more stress on a board and increase the likelihood of damage as well CAF formation.

Industry Category