DRC in PCB

By:PCBBUY 08/16/2021 10:11

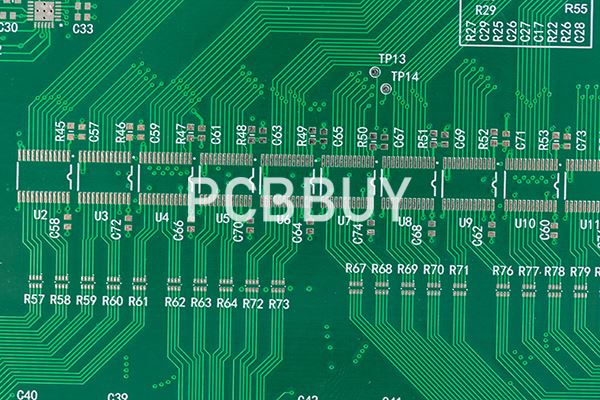

A design rule check is a set of rules used by a designer to ensure the schematic matches all manufacturing considerations and dimensional tolerances set for a board. Production processes have a margin of error for the variation in the products that are manufactured. Such variations in production yield are adjusted in the design phase itself.

In this article, we will focus on the topic and you can learn more knowledge from the content below.

What are the rules of DRC in PCB?

Electronic design automation software lets you know when a design margin is violated by stating the parameter that is out of the acceptable range. This is called a DRC error and it helps eliminate rework in the production stage.

DFM rules

DFM stands for design for manufacturing, which is the layout topology in a way that avoids all the problems that could be encountered during the PCB fabrication and assembly processes.

Drilling checks for drilling holes:

Drill-to-copper: The drill-to-copper is the land clearance between the edge of a drilled hole to the nearest copper feature. The nearest copper feature can be a copper trace, copper pour, or any other active copper region.

What is a Pad in PCB Design and Development?

Annular ring checks: To achieve acceptance for Class 2 and Class 3, follow the tables below published by Altium. The first one gives the annular ring requirements for mechanically drilled blind, buried, and through-holes on ½ oz copper:

What is DRC and LVS check?

A DRC allows one to verify the schematic and layout with regard to the margin of error you can incorporate in your design. As it allows one to check if a specific board layout correlates with the original circuit diagram or schematic of the design, it is also called layout versus schematic (LVS) check.

What are DRC errors?

Electronic design automation software lets you know when a design margin is violated by stating the parameter that is out of the acceptable range. This is called a DRC error and it helps eliminate rework in the production stage.

DFM rules

DFM stands for design for manufacturing, which is the layout topology in a way that avoids all the problems that could be encountered during the PCB fabrication and assembly processes.

Drilling checks for drilling holes:

Drill-to-copper: The drill-to-copper is the land clearance between the edge of a drilled hole to the nearest copper feature. The nearest copper feature can be a copper trace, copper pour, or any other active copper region.

Annular ring checks: To achieve acceptance for Class 2 and Class 3, follow the tables below published by Altium. The first one gives the annular ring requirements for mechanically drilled blind, buried, and through-holes on ½ oz copper:

Signal checks: The first checklist we like to implement after receiving Gerber files is signal checks. This checklist holds key parameters that include conductor width, spacing requirements, hole registration, and many more.

Solder mask checks: Coming to solder mask clearance, we can typically define it as a general isolation recommendation alongside specific details characterized by the kind of surface element(s) being isolated. Particular specifications apply to pads, which may be solder mask defined or non-solder mask defined, and drill holes, which may be plate through-holes or non-plated through-holes.

Silkscreen checks: Silkscreen to mask spacing, silkscreen to copper spacing, and silkscreen to hole spacing and route spacing

DFA rules

DFA is the process of designing a device or a PCB board by considering the ease of assembly as one of the key criteria. Here are a few DFA guidelines:

Select readily available components and validate their production. This will prevent production delays.

Apply component spacing guidelines. The component placement will determine whether the board can be assembled, the soldering techniques and the type of thermal dissipation to be used. Use component manufacturer recommendation for footprints. This will prevent pad mismatch while ensuring accurate markings for identification are present.

Apply board edge guidelines. Board shape and component placement can impact panelization.

DFF stands for design for fabrication. Therefore, as the name suggests, this addresses the issues related to fabrication. DFA stands for design for assembly. In most cases, DFF and DFA together make up DFM.

DRC (resign rule checking) in many cases is used for DFM but is not sufficient. That’s also acceptable to some extent because DRC issues detected in manufacturing can indeed have a direct impact on the manufacturability of a PCB. However, DRC is different from DFA.

Industry Category