What is Density Error in Layout through PCB Layout Guidelines?

By:PCBBUY 11/25/2021 09:22

Many issues are bound to emerge from the lack of accurate or efficient PCB layout preparation. A bigger problem that is probable to arise from a lack of PCB layout preparation is total board failure. Board failure comes in as the most significant issue that arises from poor planning or a lack of PCBs layout preparation reported by many individuals.

Do you know the errors of PCB layout? If you are searching for more information about errors of PCB layout, please check and read the content in this passage.

What are the complex PCB layout preparation issues?

Creating a circuit board withstand even some of the toughest conditions is not an easy process as one may like to imagine. While PCB layout preparation matters, such can be impeded by technical or rather complex PCB layout preparation issues. Some of the most common technical/complex factors in PCB layout preparation include:

· Coming up with the best layout needed for spacing between traces

· Trace widths

· Tolerances for the electrical factors that may affect the functionality of the board

· Clearance of traces in addition to other components to the edge of the board

The availability of some layout components may be a tasking exercise with specialized or hard-to-find components likely to increase the final product's cost. If the production of a high number of boards is necessary, this can also be a major concern.

What are the main PCB layout errors?

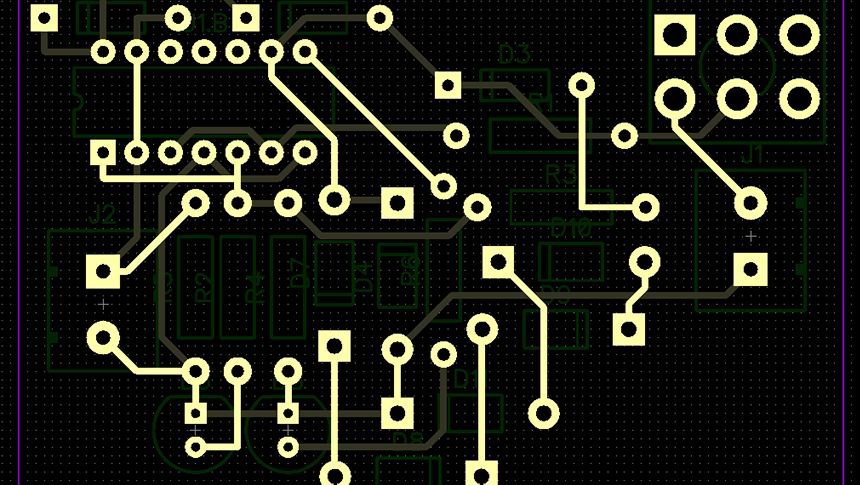

Let’s face it, while it may be complex, PCB layout is also a lot of fun. Maneuvering components around on the screen with their net connections rubber-banding between them is one of the best and most challenging puzzles that you can work on. However, as with the setup of the board prior to placement, there are some potential problems here that can cause your design a lot of issues if you aren’t careful about preventing them. Let’s start first with potential issues involving the physical footprints that you will be placing on the board.

Incorrect footprints

We’ve already talked about the importance of having the correct components in your design, but you can still have a problem if those components aren’t using the right footprints. Although this should technically be caught during design synchronization, designers should still ensure that they are using the correct footprints. Whether a PQFP is being used instead of a BGA, or the polarity of a capacitor is reversed, footprint errors like these will require a redesign if not caught the first time around.

Don’t neglect the floorplan

To ensure good signal and power integrity, PCB design circuitry must be carefully partitioned for maximum performance. This is especially true of high-density designs where every millimeter of space counts. Designers who fail to do this may have costly redesigns ahead of them to improve the performance of the board. Using the schematic to place logical groups of components or designating placement rooms on the board can be very helpful in preventing partitioning errors.

DFM is essential

Ensuring the manufacturability of a circuit board is just as important as signal and power integrity in the design. It is critical that PCB designers obey design for manufacturability (DFM) rules in their layout. These include minimum clearances around components for automated assembly equipment and test equipment, as well as room for technicians to debug and rework the board. Using the design rules and constraints in the CAD tools is an absolute must for eliminating DFM errors.

How to balance the techniques and avoid the errors in PCB layout?

You should also consider the manufacturing processes you’d like to employ to produce the board. Different methods have different limitations and constraints. You’ll need to use reference holes or points that work with the manufacturing process on the board. Always ensure holes are clear of components.

Also, keep the board mounting method in mind. Different approaches may require you to leave different areas of the board open. Using multiple technology types, such as both through-hole and surface mount components, can increase the cost of your boards but may be necessary in some cases.

Always check with your fabricator to make sure they have the capabilities to produce the type of board you need. Some might not, for instance, be able to manufacture boards with many layers — or those that use a flexible design.

What are the considerations of PCB layout?

The needs of the circuit board configurations within the system will dictate how the headers will be placed on each individual board. Here are some possibilities to consider:

· Boards that need to be parallel with each other will be stacked using straight pin headers.

· Boards that need to be side-by-side horizontally will be connected with right-angle headers.

· Boards that need to be positioned at right angles to each other will use a combination of a straight pin header on one board and a right angle mating connector on the other.

Industry Category