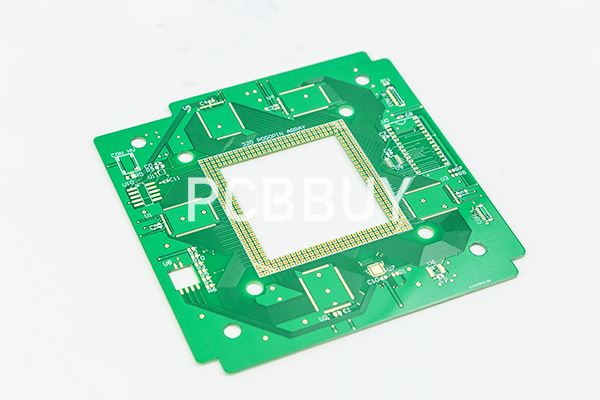

ESD in PCB

By:PCBBUY 06/19/2021 17:37

ESD, also known as electrostatic discharge damage, can disrupt SMT assembly, and disrupt the process itself. And ESD will also lead to failure of particular components of the device you are building. It is very important to control ESD during the PCB manufacturing process. In this passage we will provide everything about ESD please check and read the content below.

What is the basic overview of ESD?

ESD happens if a static charge transfers from one object or surface to another, with the condition that the second object doesn’t have identical electrostatic characteristics. If you detect ESD, it will happen either because of contact between two surfaces or materials or because the electric field had a breakdown.

That is important because electrostatic discharge is capable of endangering components’ performance and causing their failure. We will agree that it is not something that should when you are in the process of SMT assembly, which is why we will discuss how to stop ESD later.

How to generate ESD?

Take a look at three ways that can generate ESD:

• Friction – it is the contact that happens between two objects or surfaces. After you create contact and separate them again, you might notice electrostatic appearing. The simplest example of this is your clothes. You’ve surely felt static electricity when you touched your clothes at least once in your life. The problem with electrostatic in SMT assembly is that it can compromise the device's performance and its components.

• Conduction – if the parts of your device have pins and lead made of metal, they have the potential to conduct ESD. That means if they find themselves between a component and an object (body, surface). It will transfer electrostatic.

• Induction – some surfaces and objects have huge energy that might touch the electronic parts of your device. That will cause your parts to produce electrostatic themselves.

We presented three ways, but it all comes down to movement being what leads to static electricity and the potential damage.

What are the features of ESD?

Do you know the most dangerous feature of static electricity during SMT assembly, and what can lead to the biggest damage? It is that humans might not recognize ESD at all. The electrostatic discharge needs to be of a certain volume for humans to identify it. Unfortunately, even levels lower than the ones we can notice can endanger an electronic device's components.

ESD of low power is more than enough to cause huge damage to the product you are assembling. That low power cannot harm people, and it is so low that they don’t even notice the damage to the components. As for other features, it is vital to note that the ESD starts and ends quickly. It doesn’t take more than a millisecond for the electrostatic discharge to damage the components.

It is also important to note that humidity may contribute to ESD, which is why you should consider putting it under control.

How to protect SMT assembly from ESD damage?

ESD is a sneaky thing, and it can cause damage under the radar, and without you even noticing it. So, what else can you do? The best idea is to focus all your efforts on preventing ESD damage.

That won’t be easy because there are steps to take throughout the entire SMT assembly process. The key lies in identifying the most sensitive areas and keeping electrostatic from forming there. In other words, you go to the source of static electricity and prevent it. Keep in mind that you might not be able to stop all ESDs out there. However, as long as you keep things under control, there won’t be any noticeable damage.

Start with equipping the entire area where you assemble the product with anti-static features. It doesn’t matter if it is a small private workshop or a big factory. The idea is the same – eliminate as much static as possible, and minimize pleasant conditions for creating static.

Experienced manufacturers will place anti-static PVC floors and paints all over the area. It is also vital to place warnings that you can't enter unless dressed properly. Additionally, you want to ensure the floor has no scratches and clean any dust regularly. If you deal with sharp materials, be careful, and put them anywhere but on the floor.

If you have the option, use materials for components and equipment that are static-free. That will not always be possible, which is why you should keep the objects with a high electrostatic potential away from the SMT assembly line.

An excellent trick that you can use involves getting an item that has a high ESD potential. If you connect it to your components, you will ensure that it handles all the discharge hits instead of the device itself.

Finally, keep in mind keeping humidity under control as that is another electrostatic source that you can’t neglect.

Industry Category