What is High TG PCB Material for PCB Manufacturing Process?

By:PCBBUY 11/08/2021 09:55

The higher Tg point means a higher temperature requirement during lamination. And the boards will be hard and crisp, which will affect the hole and the electrical properties. Ordinary PCB materials at high temperatures, not only will be softened, deformation, melting and other phenomena, but also the mechanical and electrical properties decline sharply. General FR4 Tg is 130-140 centigrade, moderate Tg is greater than 150-160 centigrade, High-Tg is greater than 170 degrees.

If you are going to curious about the high TG material, please check and read the content for more professional information.

What is the definition of High TG PCB?

As you know, the base material (polymer or glass) is shifting from a glassy, solid, rigid state to rubbery state when the temperature goes up to a certain area, so the temperature just at this moment is called the glass transition temperature (Tg). that is to say, Tg is a mechanical property that designates glass transition temperature, that is, the highest temperature at which the substrate remains rigid. In other words, the normal PCB substrate is no only softening, deformation, melting, as well as other phenomena at high temperatures, but also there is a sharp decline in mechanical and electrical properties, which will make an effect on product life.

What are the benefits of High TG PCB?

Higher stability: it will automatically improve the heat resistance, chemical resistance, moisture resistance, as well as stability of the device if increasing the Tg of a PCB substrate. Bear high power density designs: high Tg PCB will be a good solution for heat management if the device has high power density with quite high heat generation rate.

It can achieve with using a larger printed circuit board to change the design and power requirements of a device when reducing the heat generation of ordinary board, what’s more, it also can use the high Tg PCB.

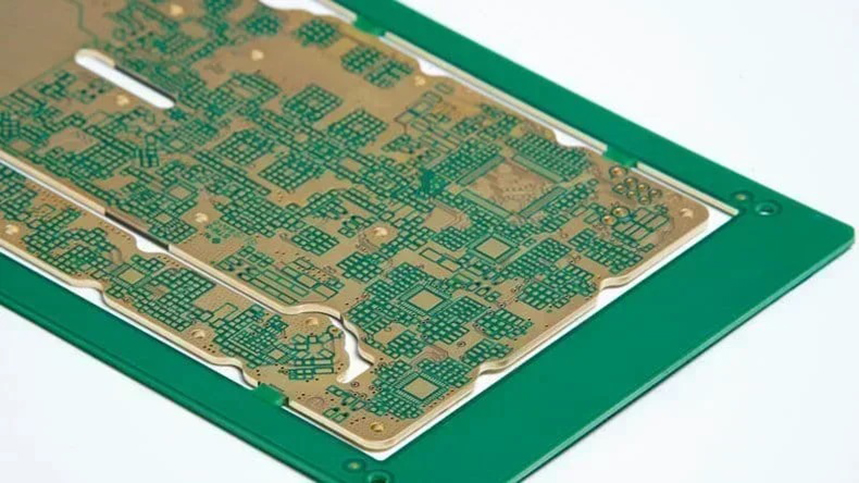

Ideal for multilayer & HDI PCBs: there will lead to high levels of heat dissipation because multilayer & HDI PCBs are more compact and have dense circuits. So high Tg PCBs are often used for the multilayer & HDI PCBs so that they can make sure reliability in PCB fabrication.

What are the specifications of High TG PCB?

The glass transition temperature of PCB, referred to as "Tg", indicates the point at which the PCB material will begin to transform. If the operating temperature exceeds the designated Tg value, the board will begin to change from a solid to a liquid state, which is likely to have an adverse effect on its ability to function.

Standard PCBs are manufactured with materials offering a TG value of 140°C, which can withstand an operating temperate of 110°C. While this may not be suitable for extreme-temperature processes that are commonplace in applications such as automotive, industrial or high-temperature electronics. In these situations, a PCB made from FR-4 material can often provide the best solution.

What are the applications of High TG PCB?

CAF - Conductive Anodic Filament: an undesirable conducting filament in the substrate of a circuit board

· Multilayer boards with many layers

· Industrial electronics

· Automobile electronics

· Fine line trace structures

· High temperature electronics

Why to choose High TG PCB?

As the rapid development of electric industry, especially for the computer as the representative of electronic products, developing toward the high performance, high multilayer requires PCB substrate material with higher heat resistance to ensure high reliability. On the other hand, as a result of development of SMT, CMT with high density pcb assembly technology, the PCB manufacturing with small hole size, fine lines and thin thickness are more and more inseparable from the support of high heat resistance.

If the Tg of PCB substrate is increased, the heat resistance, moisture resistance, chemical resistance and stability of printed circuit boards will be improved as well. The high Tg applicates more in the lead free PCB manufacturing process.

When to start High TG PCB?

Therefore, the difference between general Tg FR4 and high Tg FR4 is, in the hot state, especially in the heat absorption with moisture, the high Tg PCB substrate will perform better than general FR4 in the aspects of mechanical strength, dimensional stability, adhesiveness, water absorption and thermal decomposition.

Usually, manufacture are would like to choose high Tg material to produce high layers PCB(especially ≥10L ) or multi-layer heavy copper PCB(≥3oz) to improve high reliability/high quality. The common use high Tg material are like ITEQ IT180,Shengyi S1000-2,EMC EM827. Isola(370HR) are not common use and need specially purchase and price will more expensive than common use high Tg material.

There are also material which Tg value can reach to more than 190℃ or 210℃, but it is rare to use it, the price is higher than 370HR, like Isola FR408HR, this also belong to high frequency material.

Industry Category