IPC PCB

By:PCBBUY 06/01/2021 18:28

PCBs are the brains of all electronic devices. They are incredibly important to the functioning of society today. Everything from your Google Home to your computer to your key fob for your car has a circuit board. Because they are used in so many things, it is important that they comply with IPC standards.

In this passage we will focus on the IPC PCB and if you are curious about our topic, please check the content below to get more information.

What is IPC standard?

IPC is the trade association for the electronic interconnection industry. It provides industry standards for the assembly and protection of electronic equipment, as well as training, market research and public policy advocacy.

IPC is a member-driven organization and has more than 3,000 member companies around the world. Its members include companies in all aspects of the global electronics industry, including designers, suppliers, board manufacturers, assembly companies and original equipment manufacturers.

The organization got its start in 1957 as the Institute for Printed Circuits. It later changed its name to the Institute for Interconnecting and Packaging Electronic Circuits due to the expansion to packaging and electronic assemblies from bare boards. In 1999, it adopted the name IPC, with the tagline Association Connecting Electronics Industries.

IPC has its headquarters in Bannockburn, Illinois, and has other offices around the United States and the world, including in India, China, Sweden and Russia.

The American National Standards Institute (ANSI) has accredited IPC as a standard-developing organization. What are the IPC standards? They are the most widely recognized acceptability codes in the electronics industry. The organization publishes standards for nearly every phase of the electronic product development cycle, including design, purchasing, assembly, packaging and more.

IPC currently has more than 300 active standards and more than 1,000 standards in its resource library. Electronic designers all around the world use these standards for everything from generic reference designs to more customized blueprints.

Committees of volunteers from across the electronics industry draft, edit and vote on IPC standards. More than 3,000 industry professionals across the globe participate in this process. Committees can include people from around the world, as members can participate via in-person meetings, teleconference and email.

The association provides validation services programs, including a standards gap analysis that helps organizations address manufacturing issues and determine what they need to do to reach compliance with standards. It maintains a qualified manufacturers list and qualified products to help you determine if a product complies with IPC standards.

There are more than 110 IPC-licensed training centers around the world. The organization also offers online and multimedia education and training resources. It hosts educational events, as well as technical and management conferences, including IPC APEX EXPO, which is the largest electronics manufacturing industry exhibition in North America, and APEX South China.

Additionally, the organization conducts market research and does work in government relations and environmental policy. IPC advocates for the electronics industry with regulators around the world.

What is IPC PCB?

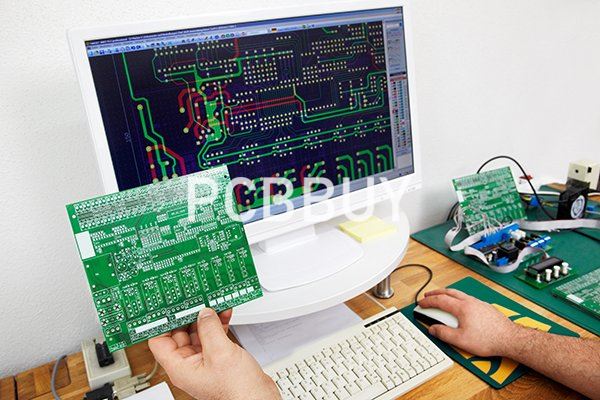

Since IPC creates standards for the electrical and electronics industry, it also plays a crucial role in producing standards for PCBs. You can find IPC standards for PCB manufacturing at every stage of the PCB production process, including design and manufacturing.

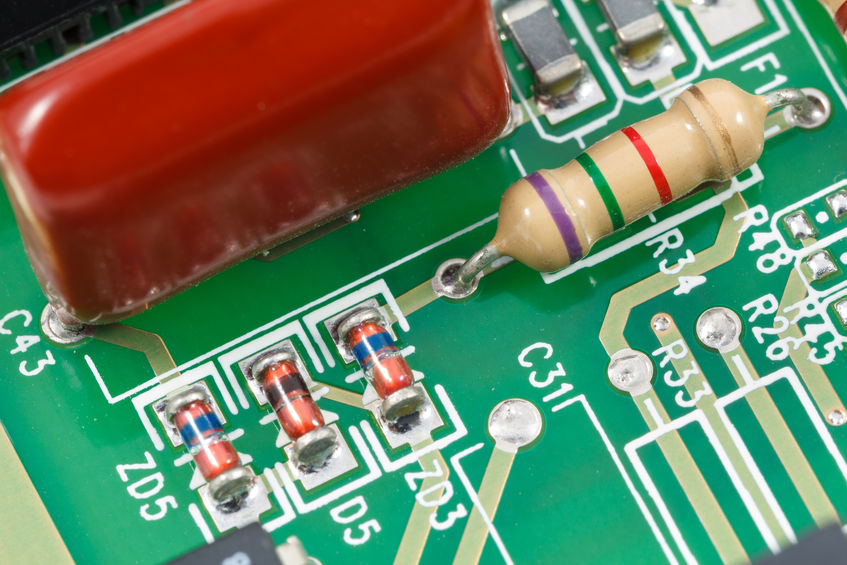

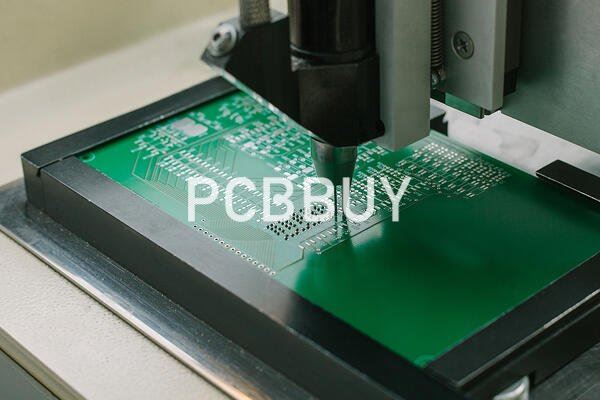

For example, at the beginning of a PCB’s creation, IPC plays a role in setting standards for file formats, PCB design software, design guides and electronic product documentation. These standards also affect the appropriate materials for PCB board assemblies, surface mount devices and surface finishes. Additionally, they play a role in testing and judging the acceptability of printed boards.

IPC PCB standards also set requirements for soldering electrical and electronic work in PCBs. These soldering standards often relate to reflow and wave soldering, as well as solder splices. Companies also rely on them to see if their electrical and electronic assemblies are acceptable during manufacturing. IPC standards also cover cable and wire harness assemblies. Finally, they set acceptability standards for the manufacture, inspection and testing of electronic enclosures before the PCB is released as a final product.

What Do IPC Classes Mean?

IPC separates PCBs in electronics manufacturing into three different classes. These classes signal the quality of the PCB, with Class 1 being the lowest quality and Class 3 being the highest quality. Companies that produce electronics with PCBs should be aware of these different classes since they dictate the safety and performance specifications companies must meet in inspections and the quality standards that apply to the products.

Learn more about how IPC defines the three classes of electronic products below:

Class 1 – general electronic products: Class 1 products are for applications in which the primary requirement is the function of the completed IPC assembly. This class includes most typical everyday products and consumer electronics.

Class 2 – dedicated service electronic products: Class 2 products must have high reliability and extended life. Uninterrupted service is preferable but not critical. The use environment of the product typically wouldn’t cause failures. Some examples of these products include microwaves and laptops.

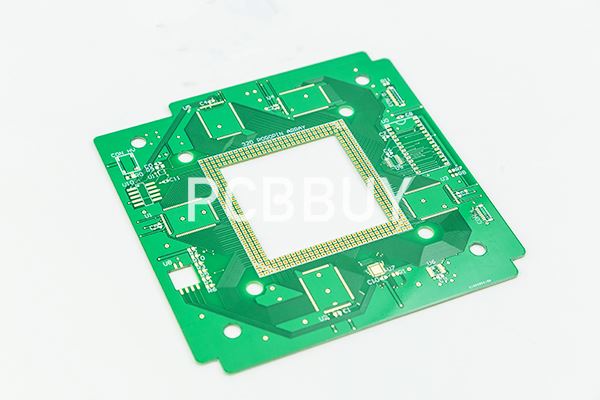

Class 3 – high-performance electronic products: Class 3 products must provide continued performance or performance on demand. There can be no equipment downtime, and the end-use environment may be exceptionally harsh. The equipment must function when required. This category includes critical systems such as life support systems. Class 3 PCBs are used in advanced medical equipment, clean technology and machine learning.

Industry Category