What is OSP in PCB & What is the Advantage in Manufacturing?

By:PCBBUY 12/30/2021 09:59

OSP needs adequate care during transportation and operation because OSP technology’s generated preservatives can cut as thin. With the long exposure of PCBs with OSP as a surface finish to humidity and high temperature, there is a possible generation of oxidation on PCBs’ surface. As a result, it can result in low solderability. Thus, some of the principles of soldering technique to use include:

Do you know the basics of OSP in PCB in manufacturing process? If you are searching for the information of OSP PCB in manufacturing process, please check and read the content of OSP in PCB for professional knowledge.

What are the features of OSP PCB?

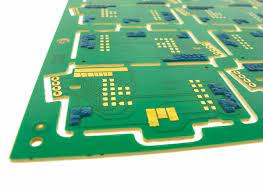

OSP is a water-based, organic surface finish that is typically used for copper pads. It selectively bonds to copper and protects the copper pad before soldering. OSP is environmentally friendly, provides a coplanar surface, is lead-free, and requires low equipment maintenance. However, it’s not as robust as HASL and can be sensitive while handling.

Pros:

· Lead-free

· Flat surface

· Simple process

· Repairable

Cons:

· Not good for PTH

· Sensitive

· Short Shelf life

What are the benefits of OSP PCB?

The major point is the low cost and easy processing makes this process of surface finishing more popular across the printed circuit board industry. Few advantages are enlisted below:

Simple PCB manufacturing process: Printed circuit boards coated with OSP are easy to rework and maintain. Therefore, it is an advantage for PCB manufacturers to repair the surface finish coating with less time and cost, once coating found damaged.

OSP coated boards gives good performance in terms of solder wetting and joining between flux, vias and pads.

Because of application of water based compound in OSP surface finishing, makes it environment friendly. Therefore this can be termed as a green electronic product which is catering to the green regulations.

Implementation of simple chemical compound and less complexity of process it is of low cost. With most of the chemicals of OSP there is no need of solder mask ink. But some chemicals require a little proportion of solder mask ink in some special cases.

Storage time is long for the printed circuit board if coated with OSP. It is implemented with single-side SMT assembly as well as double sided prototype PCB assembly.

What are the factors of OSP that effect PCB quality?

A range of factors will affect which type of PCB finish you decide to use. It’s essential to consider all of these factors as an integrated whole. Though they all hold weight within the process, your finished PCB may not turn out as intended if you favor one characteristic greatly over the others. For example, you may choose lead-free HASL because of its cost-effectiveness but later realize that its co-planarity is lacking compared to other finishing processes.

Below are some crucial components to keep in mind when investigating the various PCB surface finishes.

1. Cost

How much you spend on surface finishing is determined by the type you choose. Finish quality also factors into the cost. HASL finishes are more affordable than ENIG types, but they may not meet the precise quality standards you expect.

The price of fabricating the board itself will also matter. After the initial fabrication, will there be room in your budget to select more advanced finishing methods such as ENIG? PCBs for industries like consumer electronics are decidedly less expensive to manufacture, which can allow you to utilize more costly finishes for higher-quality results.

2. Volume

Production volume can significantly impact which type of surface finishing you use. For example, a surface finish consisting of immersion tin will begin tarnishing soon after being deposited onto the copper PCB. However, using a high volume of PCBs can help you avoid tarnishing. If you have a small batch, it may be better to go for a finish like immersion silver.

3. Cosmetics

Processes like HASL and OSP tend to offer a better aesthetic value than ENIG, which is another component that could influence which kind you select. Do you need a shiny surface that’s less susceptible to creep corrosion, whiskers and similar issues? You may want to avoid dealing with materials like silver and tin and choose other options that are less likely to cause significant corrosion.

Industry Category