What is PCB Insulation and Why is it Important to Manufacturing?

By:PCBBUY 12/06/2021 09:18

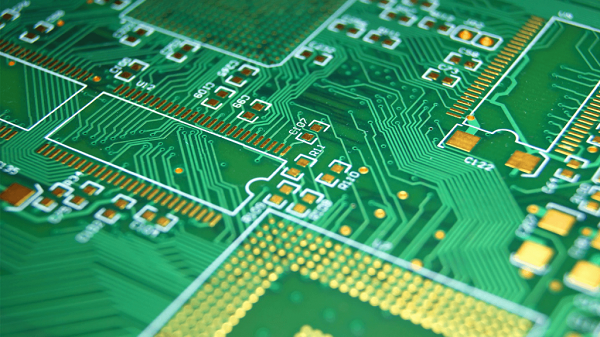

PCBs are generally referred to according to the number of signal layers that they contain. Although there are still some cases where single-layer boards are used, today, most PCBs are multilayer due to their compact size, higher quality, and propensity to accommodate more complex designs. These advantages do present other challenges, including more complicated signal routing. Instead of clearance and creepage on the board surface being the primary signal integrity issues for operation, the use of multiple layers and vias introduce PCB insulation between layers as a consideration.

If you are looking for more information about PCB Insulation and the importance, please check and read the content below in this passage.

Wanna know PCB knowledge? Check and read for more.

Why PCB Insulation Is Important?

As you can see, PCB or printed circuit board is one of the most important parts of the electronic devices and gadgets these days. Most of the devices in your house come with this board in it. The printed circuit board allows the electronic devices to function properly and correctly. Without the presence of these boards, it is impossible to operate the phones, computers and televisions. In order to operate this board, electricity plays a vital role. Without it, the PCB will not be able to function properly.

The printed circuit board contains some copper wiring which are printed and everyone knows that copper is a natural conductor of heat and electricity. But these electrical components can get quite hazardous if they are not properly insulted or enclosed in a case which is non-conductive in nature. If not, then it can become quite hot. Thus, PCB insulation is very important in order to prevent the corrosion of the copper elements. The insulation is also important to reduce any kind of accidental contacts with the conductive material.

With the proper insulation, you can keep your printed circuit board from getting overheated. Overheating can cause severe damage and even bursting into flames. This can be quite dangerous and damaging for the board as well as the device. Some of the main objectives of insulation for printed circuit board are:

· To minimize or even eliminate the interference of the signal between two adjacent layers

· To aid the proper distribution of thermal while assembling

· To maintain an adhesion during the cycling of assembly temperature

· To aid in the signal as well as power integrity

In short, the insulation can help the printed circuit board assembly as well as operation. Sometimes multiple layers are used for insulation. This is done to ensure proper functionality and operation of the printed circuit board.

How to choose the right material for PCB Insulation?

Common PCB insulation materials are often formed into non-conductive substrates, which meld together in several layers to allow electrical currents to travel correctly throughout the board. Simpler PCBs may be single-sided or single-layered. Complex PCBs, such as those used in high-speed digital communication, may be comprised of over twenty layers.

A PCB insulation calculator can help you determine creepage distances and clearance, which will factor into the exact type and quantity of insulation materials you may need. Creepage distance is the shortest distance between conductive parts, and clearance refers to elements separated by air, not substrate. Understanding creepage distance and clearance is essential for calculating PCB insulation.

A PCB manufacturing company can choose to insulate with many different materials, ranging from the inexpensive plastic-like FR-2, to robust and sturdy metals such as aluminum. The intended use of a PCB often determines the materials used to insulate it. For example, the PCB in a cheaply made electronic toy will not require the same kind of insulation as the PCB in a satellite. To better understand PCB insulation and insulation materials, let’s explore the five most common forms of PCB insulation materials.

How to process the coating of PCB Insulation?

A freshly produced PCB comes with the expectation of perfect performance. As well as the projection that all components of the PCBs are well suited for work without itches.

Nonetheless, the PCB is open to mitigating factors that could hamper its efficiency. Environmental variables such as corrosion, dust, temperature and dirt could affect the PCB. Also factors such as voltage surge, overburden voltage and accidental impact could mitigate.

The durability and integrity of the PCB could be reduced as a result of these demeaning factors. As such, manufacturers adopted the PCB insulation coating to remove these negative factors. The insulation coating provides coverage for the PCB against all environmental variables. It is suitable for use in a broad range of environments to protect the PCB from all kinds of mitigating factors.

The coverage provided by the insulation coating enhances higher current incline. Thus, producers are able to match the compactness and integrity demands by end users.

Define PCB Insulation Coating

Insulation coating means the method of applying resistant materials to the PCB layer. This can either be through brushing, dipping or spraying of the coating material on the PCB. Thus, the PCB is well protected against destruction caused by tough environments.

Furthermore, the PCB insulation coating also enhances the stoppage of electrical discharge. Insulation coating increases the lifespan of the PCB. Mechanical and heat pressure, damages during installation and brutal handling are practically eliminated.

Industry Category