What is PCB chemical used for?

By:PCBBUY 05/31/2021 17:35

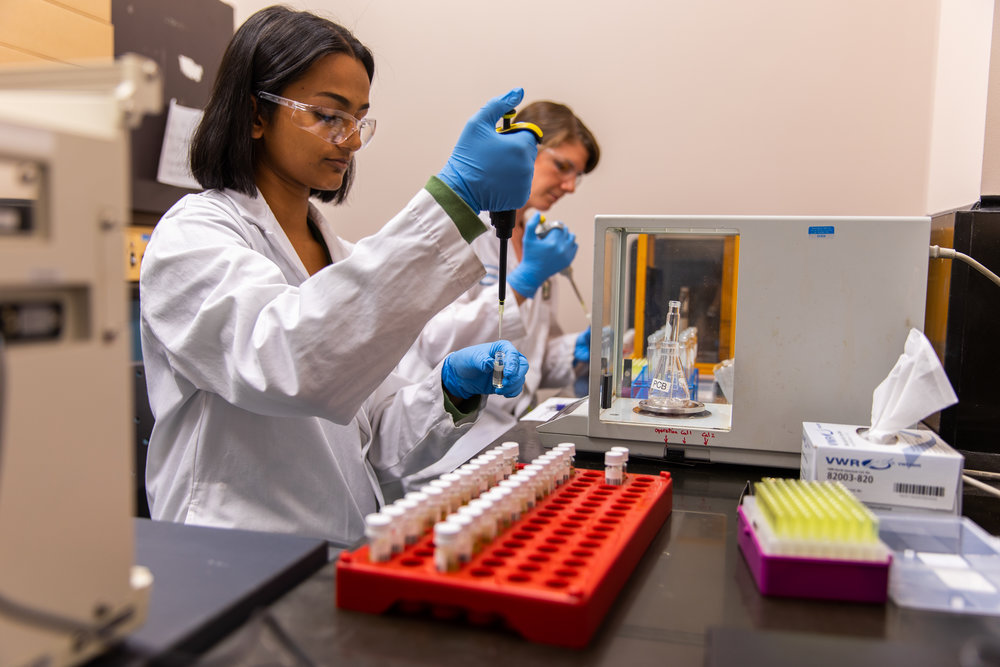

There Are Many Chemicals Used in PCB Manufacturing. Cleaners, replenishers, stripping, and other chemicals are all crucial in the PCB manufacturing process.

It is necessary to know what chemicals are used in printed circuit board manufacturing is good, but what’s more important is to make sure you take the necessary precautions and ensure a high-quality end product.

In this passage, we are talking about the chemical use in the PCB manufacturing process and please follow the content we provide below.

Chemical for cleaners and finishing touches

When bare copper is not properly coated, it oxidizes over time. Oxidation is a process that happens naturally. It occurs when a material is exposed to oxygen.

To put it into perspective — oxygen affects copper much like it does an avocado. When an avocado is opened and exposed to oxygen, it turns brown quickly, but with proper protection — like wrapping it in aluminum foil and putting it in a cold setting — it will keep its green color longer.

There’s no way to stop the oxidation process entirely, but you can slow it down with the proper coatings, protection, and storage measures in place. If a bare PCB has a small amount of oxidation, it can be cleaned. Mass amounts will be more challenging to clean and can alter the functionality of the part, so it’s sometimes more efficient to replace it altogether. Still, a good cleaning can enhance the performance and longevity of the PCB.

There are many solvent cleaners to choose from. The most commonly used copper cleaners will have one of the following titles: acid cleaner, alkaline cleaner, metal surface cleaner, or micro etchant for copper. Each has the ability to clean copper, but with minor differentiators.

All in all, you’ll want to look for a cleaner that has a mildly acid aqueous solution or that uses a small amount of silicates. Before soldering and etching, the PCB should be cleaned to remove traces of oil, fingerprints, grease, or other contaminants.

Chemicals for PCB development

Along with cleaners, there are chemicals used during PCB development that should be noted.

Replenisher

During the assembly process, a printed circuit board encounters wear and tear. Using a replenisher on it will help make the PCB work normally during development.

Copper can get stripped in the assembly process, and a replenisher essentially neutralizes, brightens, and restores the balance between components of the developer.

Cleanserpcb manufacturing chemicals

In the PCB development process, cleansers are used to apply a dry photoresistant film. This is essential for PCBs because it gives the board the ability to resist etching or damage from solvents when exposed to light.

Antifoams

Antifoams are used to reduce the natural foam produced by sprays and other foamy chemicals used in the PCB manufacturing process. These are mostly used during development and stripping.

Chemicals for etching

Etching is the process of a material being removed from another material’s surface. In PCB manufacturing, etching is one of the final steps of the manufacturing process.

Etching is done to remove excess copper to reveal the desired circuit patterns. There are different ways to complete etching, which are chemical etching, laser etching, and plasma etching. All of these methods have the same effect, just implemented in different ways. Plasma etching is the most precise way to implement etching because it is accurate on a tiny scale.

Chemicals for Stripping

In the printed circuit board manufacturing process, resist stripping is used as a cleaning method to remove unwanted material from the wafer without disrupting the surface materials. This is done before the fabrication process to ensure there are no foreign materials or contaminants present.

There are different ways to implement wafer stripping based on the contaminants involved and requirements for removal; the commonly used methods are photoresist stripping, organic stripping, and dry stripping.

Chemicals for PCB plating

Plating chemicals are used to protect exposed copper and prep the materials for the soldering process. This is done to help combat oxidation as well. Copper plating is also referred to as copper coating, copper finishing, or surface finishing.

Industry Category