PCB package

By:PCBBUY 05/28/2021 17:34

Packing a PCB is more than just a decorative affair. Although PCBs appear as hulking slabs of copper and fiberglass, they are deceptively delicate. They cry out for protection.

During shipping, packages can be subjected to all manner of crushing, shaking, tossing and dropping among many other forms of physical damage. Damage is not always visible to the naked eye but can be just as fatal. If you’ve also arranged for your ONLINE PCBs to be populated for you, your package will be extra vulnerable to electrostatic damage or moisture penetration.

As the last step of manufacturing, we will lead you to learn the details about PCB package.

What Is Anti-static Packaging?

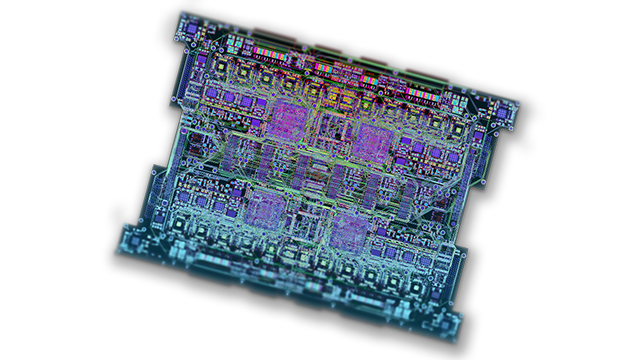

Electrostatic discharge (ESD) is the rapid transfer of electrostatic charge between bodies of different electrical potential when they come into contact with each other. ESD is one of the major causes of component failure. Although some components are robust enough to resist damage from ESD, parts like integrated circuits and semiconductors can be permanently damaged from just a small jump in current. With the size of integrated circuits getting smaller, this means that devices have become more susceptible to damage by ESD.

Examples of components sensitive to ESD include MOSFETs, as they have a very high impedance, which makes charge dissipation more difficult. And even if components do not fail immediately, ESD can gradually cripple the functionality of devices down the road. Thus, if you have components highly sensitive to ESD, it’s reassuring to know that the packaging isn’t doing any harm.

In addition, electrostatic adsorption of dust will reduce the insulation resistance of the component (shorten the life). The heat generated by the electrostatic discharge electric field or current can damage the component .

One of the most basic means of protection against ESD during shipping is the use of anti-static bubble wrap. Besides acting as a cushion against all the tossing involved in the shipping process, unlike regular bubble wrap, it will not generate electrostatic charge and helps dissipate it away. The anti-static bubble wrap is recognizable from its distinctive pink color, due to the anti-static coating applied.

ESD bags or pink poly are anti-static bags used for storing electronic components prone to ESD damage, much like anti-static bubble wrap. Made of polyethylene, it doesn’t generate ESD and can contain a layer of bubble wrap for extra cushioning against physical shock. Pink foam is also widely used for the same purpose.

Another type and more superior form of ESD protection is the use of conductive anti-static bags. You can tell these from regular anti-static bags, or dissipative anti-static bags, as they have a shiny metallic layer often with a Ziploc style seal. These do well for long term storage, shipping and handling since they actively shield against charges. Hence they are also known as shielding bags. Therefore, the contents are effectively protected from any external charges and are vital in protecting bare components like MOSFETs.

What Is Moisture-proof Packaging?

Moisture in the air can damage the electronic components on the PCB in many ways. For example, a small water spot accidentally traverses the trace on the circuit board and may cause a short circuit. Or electronic equipment may corrode the traces on the circuit board due to moisture.

When used in outdoor applications, one of the most common causes of PCB degradation is due to moisture. In the field, your board will likely be enclosed in a suitable waterproof housing, but even before they are installed, the boards could be exposed to moisture during shipment. Even bare PCB boards can be adversely affected by moisture. If your PCBs are going to be traveling long periods at via sea freight, or through areas with a humid climate, pay attention to the moisture-proof properties of the packaging.

Your boards should be in a sealed moisture barrier bag, with a little bag of desiccant. Desiccant is a drying agent packed in a porous pouch, to enable moisture to go through the pouch and be absorbed by the desiccant. The purpose of the desiccant is to absorb any moisture from the air left inside the bag after it has been sealed, and also any moisture that penetrates the bag. The desiccant remains dry even after it is fully saturated with water vapor.

What Is Anti-vibration Packaging?

Due to the possibility of rigorous handling during shipment, PCBs can be subjected to shock or flex damage if insufficient anti-vibration packaging is used. This can lead to shock or flexing of a PCB. To prevent that from happening, sufficient padding should be used to limit movement within the outer packaging and protect vulnerable areas such as exposed pins.

packaging technology can be subdivided into the following categories:

1. Compressed packaging

Pack fragile items with elastic materials for reinforcement, so that the energy from vibration or impact can be absorbed and guided to the strongest part of the contents. When the elastic material is shock-proof, it can effectively absorb energy, disperse external force, and effectively protect the contents.

2. Floating packaging

It is basically the same as the compression packaging method. The difference is that the elastic material used is a small pad, which can be displaced and flowed, so that it can effectively fill the gap of the directly stressed part and disperse the impact of the contents.

3. Wrap package

Various types of sheets are used to wrap a single piece of content into the outer packing box. This method is mostly used for shockproof packaging of small items.

4. Mold box packaging

The system uses the model to make the material into a mold box with the same shape as the product, and uses it to package the product to achieve the shockproof effect. This method is mostly used in the packaging of small, lightweight products.

5. In-situ foam packaging

Fill the foam material between the contents and the outer packing box.

Industry Category