PCB printer

By:PCBBUY 08/02/2021 17:20

Modern electronics have come a long way, with a technique developed about 500,000 years ago. We are not talking about the invention of silicon that goes back even further, a couple of billion years. We mean the creation of engraving, "a practice used to incise a design on a hard and flat surface by carefully cutting accurate grooves into it."

In this passage, we will focus on PCB printer and you could check the content below for more professional information.

What is the development of PCB prototyping?

You may know that the conventional Process entails outsourcing your PCB prototyping to your supplier. That said, thanks to the invention of PCB printers, a majority of companies now have the chance to develop prototypes on their own. The PCB printers are capable of making PCBs without the need for engraving. They achieve this by squirting a particular type of ink called conductive ink on a flat and hard surface.

You will be glad to know that work is now in progress. Printers that can easily print electronic circuits rather than circuit boards are under development as well. This effort will help us print a simple four-bit micro controller on cardboard directly. Creating smart clothes and intelligent packaging is the goal here.

What are the types of PCB printer?

PCB 3D printer

PCB printers utilize dielectric and conductive inks to generate PCB from scratch, and a few of them can apply solder paste and application components. That is what makes them an excellent choice for a one-stop and hassle-free prototyping solution at your facility.

With the rise of 3D printers, there are endless possibilities for both rapid prototyping and home production. That is because you could quickly develop any model with the use of a 3D program. Then, you can print the design in 3D with ease.

Create Models in your Home

Even using a conventional 3D printer, you may practically create any model in a simple 3D modeling program and then print the model out within the comfort and convenience of your home.

Diode Lasers

You should know that diode lasers, which are compact and small, have a comparatively low power output than most CO2 lasers on the market. That said, it is okay for our purposes.

At every stage of new product development, engineers and electronics designers need to get prototype boards ready for testing purposes.

Keep in mind that the current standard that involves subtractive manufacturing when it comes to PCBs is often a multi-stage process that is both material and labor-intensive and is, as a result, often outsourced.

How PCB 3D printers can help?

However, PCB 3D printers bring together precision inkjet deposition printers, sophisticated software, and advanced nanochemistry, capable of satisfying the needs and requirements of rapid prototyping. Also, it can considerably cut down the time spent on prototyping from several weeks to hours. And the good news is that it is true even for the most intricate and complex PCBs.

These printers can also help save considerable money and sometimes even allow you to design and create models, which would usually be quite tricky, time-consuming, or even impossible to design and produce. Alternatively, in some cases, it would be cost-prohibitive with the current manufacturing processes.

In the end, this can help in increasing the overall quality of your final product and even lead to the production of an entirely new and exciting world of electronics. The possibilities are many.

PCB 3D printers can provide high resolution, speed as well as conductivity. Besides, you can have more freedom and creativity to express what you imagine because of quicker prototype turnaround times and more regular iterations. Also, you can experiment with various designs and geometries, which can lead to better products and fewer errors.

PCB Laser printer

There are many ways to make your very own PCB at home. In most cases, the best and lasting results are generated by using a process called photoresist. A suitable PCB covered with photosensitive paint is meticulously exposed through a mask to the UV light during this process.

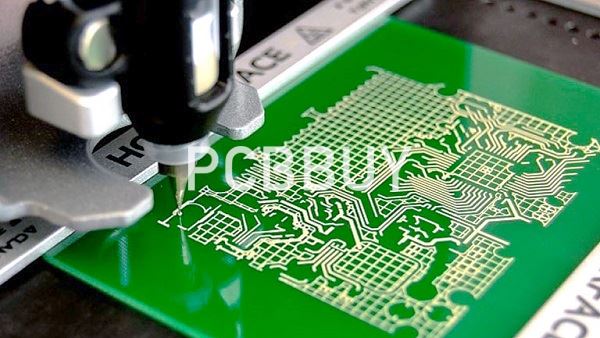

After that, exposed paint is slowly washed away, and the uncovered copper is etched. PCB laser printer is used to import the PCB layout. It is introduced in the form of a bit-map image and is printed out in a manner, which resembles a paper laser printer.

It can cover the entire surface of this PCB. The Process goes line by line. The laser turns off and on to recreate the precise image pattern. You have to ensure the Process where the laser passes over your PCB is fast. It will help you get a decent resolution as well as a short printing time. Keep in mind that this will require a short switching time and a high bit rate of laser information.

PCB Stencil Printer

Stencil printing is getting popular these days. It is the Process where solder paste is deposited on printed wiring boards (also known as PWBs) to establish electrical connections. The next stage, after printing, involves component placement. Keep in mind that the materials and equipment used at this stage are usually solder paste, stencil, and a printer.

Industry Category