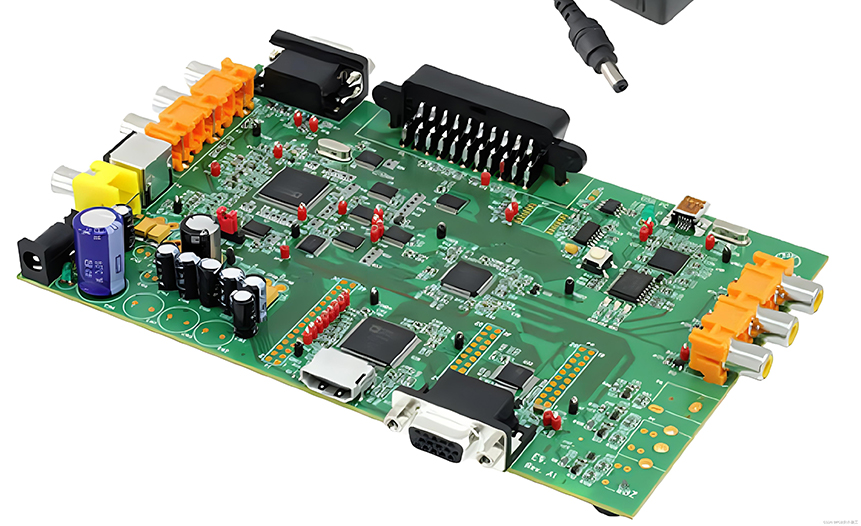

PCB programming

By:PCBBUY 06/21/2021 18:15

After PCB manufacturing, there are several methods programming assembled PCB. Among all the programming methods there are advantages and disadvantages for each one. In this passage, we are talking about the methods, please read the content below and save money and time for your boards.

What are the main obstacles in PCB programming?

·Some of the programming devices and fixtures can have a lead time.

·When the PCB cannot be determined in advance, whether to support the chip programming software used will encounter a common problem.

·Any difference in the part number suffix could result in different voltages in the pin or different timing parameters in the programming PCB board algorithm.

Planning will guarantee that you have ordered all the necessary fixtures and confirmed the programming software's compatibility long before the assembly start date has arrived. Otherwise, you will be halting the assembly release date until all the parts are programmed. It can become extremely costly if you want to expedite the PCB fabrication and get stuck in putting the complete assembly on hold.

What is PCB programming IC from the factory?

The easiest way this can be done is by getting ICs programmed from the manufacturer beforehand. You can also do this from any of the distributors who sell the parts. The Mouser and Gigi Key have offers for programming at a much lower price. They also provide an additional service for the same at discounted rates. When you have the ICs preprogrammed from the manufacturer or distributor, you no longer have to program them at the time of assembly. It will thoroughly remove the necessity for you to get a connector for programming. You also won’t have to imprint on the PCB to manufacture it at a lower cost for a much smaller product.

The con to the preprogramming feature is that if there is a production fault or an issue in the change of built, you have to force an upgrade when things are in the middle of production, and then you have zero flexibility. We must reprogram the IC. If there was any programming header and chosen to eliminate that, then it will become necessary. Without that, there is no way to remove chips that have an incorrect code.

If you decide the method for programming the PCB board, then this is one option that has no flexibility. However, if you are programming bootloaders, then you can freely choose this method. The requirements change very rarely, so you will be fine paying the manufacturer and distributor's setup fee per unit.

What is PCB programming of dedicated headers?

It is a reasonably common technique through which you can program a device. It will make sure you can establish a connection easily through the program. It will also allow you as an end-user to have the flexibility to remove and get different software.

One problem with this process is that the connector part may accumulate charge, and we need to assemble it. These connectors are some of the most expensive inventories in the list of the things necessary to construct a circuit board. So, whenever you try to do a finalized run, reducing the connectors' cost should be a priority.

It can give negative incorrectly at the time of programming and testing. A widely used and known example of this is USB connectors. When in production, changing the functionality over USB is usually better as it is repeatable.

What is PCB programming of manufacturing and test jigs?

Programming is known to use a jig made of a Pogo Pin. If you are considering doing high volume runs, this is an ideal solution. These contacts are spring-loaded, and they make an excellent electrical connection between the PCBs. We can link the contacts in the PCB to be programmed.

The jig is not only limited to programming. It can also test all the different kinds of utilities on the circuit board. The programming jigs can be used to set up to be able to program the complete panel. It only takes one pass to complete the group. It is excellent for increasing production speed and testing. The programming jig issue can be that they are pretty challenging to build, which also makes them quite expensive. It means it can be used only for runs above medium volume, balancing out the cost of tooling.

What is PCB programming of universal headers?

Universal headers are an option that is somewhere in the middle of the methods we already discussed. The tag connects also creates cables that come with pre-manufactured pogo pins. The specific program is connected to one end of the cable. The other side connects to the contacts of the circuit board. Many other companies have products that are similar to standard pogo adapters.

This kind of programming solves the issue of needing a header that is fit for the work and has the requirement to build a pricey programming jig. It makes it ideal for low to medium volume.

Industry Category