What is Rogers PCB Material with 5 Common Information?

By:PCBBUY 10/29/2021 09:41

If you are using PCB in space technology, mobile networking, microwave application then Rogers PCBs will give outstanding performance over any other PCBs. As rogers PCBs price is high compared to other PCBS but the improved performance and the extra abilities make it cheaper than others. Thus Rogers PCBs can be preferred over any other PCBs. Extensive businesses and organization in several industries gives preference to Rogers PCBs because of it high performance and reliability.

Thus while selecting PCB for your project it is required to know that how it is better than Rogers. And if you are going to learn more information about Rogers PCB material, please check and read the content below for more knowledge.

If you want to order PCB product, please check and custom your order online.

1. What is the basic definition of Rogers PCB?

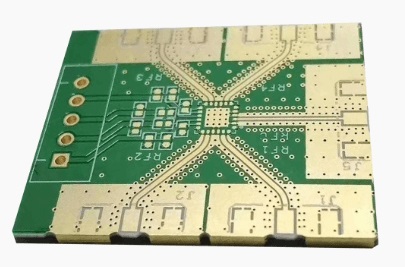

Rogers is a company that manufactures the laminate materials that are used to make circuit boards. Most circuit boards are made of a material known as FR4 (Flame Retardant level 4), which is a glass fiber / epoxy composite, with copper foil laminated on one or both sides.

Rogers will sell you FR-4 laminates (FR-4 core with copper laminate), they are better known for cores with better high frequency properties, such as PTFE (Teflon). They’re more expensive than fiber glass, but are less lossy at high frequencies. This makes them be good for RF circuit boards.

2. Why to choose Rogers PCB?

The benefits of using Rogers PCB are as follows:

· Rogers PCB has a low moisture absorption feature, low thermal expansion, and solid dimensional stability for different conditions.

· The material of the Rogers PCB is compatible and it’s easy to fabricate because the PCB is as thin as 0.1mm.

· Rogers PCB has excellent thermal management and it’s ideal for electronic devices and circuits that produce excess heat.

· With Rogers PCB, there’s the reduction of outgassing in space applications.

· The Rogers PCB matches trace locations and dimensions, leading it to enhance impedance control.

· Rogers PCB provides steady high-frequency performance.

3. What are the crucial details of Rogers PCB?

It is a well-documented fact that circuit boards are vital for electronics, something that you must know as an electronics enthusiast. Therefore, getting everything right, ranging from the material choice to the PCB manufacturing company, becomes pivotal. As you would expect, RayMing PCB and Assembly can provide you with high-quality printed circuit board manufacturing and assembly. However, diverse printed circuit board materials exist, including HDI materials, FR4, and Rogers PCB material.

So what material should you use when it comes to your PCB production needs? This article will focus on Rogers PCB and everything else you need to know regarding this PCB material.

4. What are the applications of Rogers PCB?

The Rogers PCBs have numerous applications spanning diverse sectors. It includes the following.

· You can use the Rogers PCB as crucial parts of antennas for the cellular base station, direct broadcast satellite, communication systems, microwave equipment, 5G modern stations, carrier-grade enabled Wi-Fi, etc.

· Automotive industry. The Rogers printed circuit boards can get deployed in automated/mechanized test equipment (ATE), automotive radar, sensors, etc.

· RF Engineering. You can also deploy the Rogers printed circuit boards in power amplifiers, IP infrastructure, RF Identification tags, etc.

· Aeronautic engineering. The Rogers PCB can also get deployed in ACAS or aircraft collision avoidance systems, backhaul radios, microstrip antennas, etc.

· Rogers PCBs also get utilized in DAS and ADAS (advanced driver assistance systems), among other useful computer areas.

· In the military, the Rogers PCB get utilized in radio communication systems, jamming systems, etc.

5. What are the considerations for selecting Rogers PCB?

Being thorough with your application requirements are extremely crucial, especially in case of complex PCB designs. When selecting Rogers PCB materials, you may consider following pointers:

· Ensure the material does not absorb any moisture when immersed in water. Although this may sound too unreal, the absorption rate should not be more than 0.2%. Materials with low absorption rates will have better thermal and electrical properties.

· Dielectric constant must be stable in high operating frequency applications. The high value of the charge in a PCB material enhances capacitance and voltage through the PCBs.

· Things expand when heated and contract when cooled. This simple principle also applies to PCBs when they are exposed to heat beyond the set glass transition temperature. The rate at which they expand beyond this temperature is called the coefficient of thermal expansion and is measured in parts per million (ppm). This is an important factor to check when using Rogers’s materials.

Industry Category