SMT PCB

By:PCBBUY 05/27/2021 17:46

There are many components in kinds of electronic equipments these days. Rather than using traditional components with wire leads like those that may be used for home construction and kits, these components are mounted onto the surface of the boards and many are minute in size.

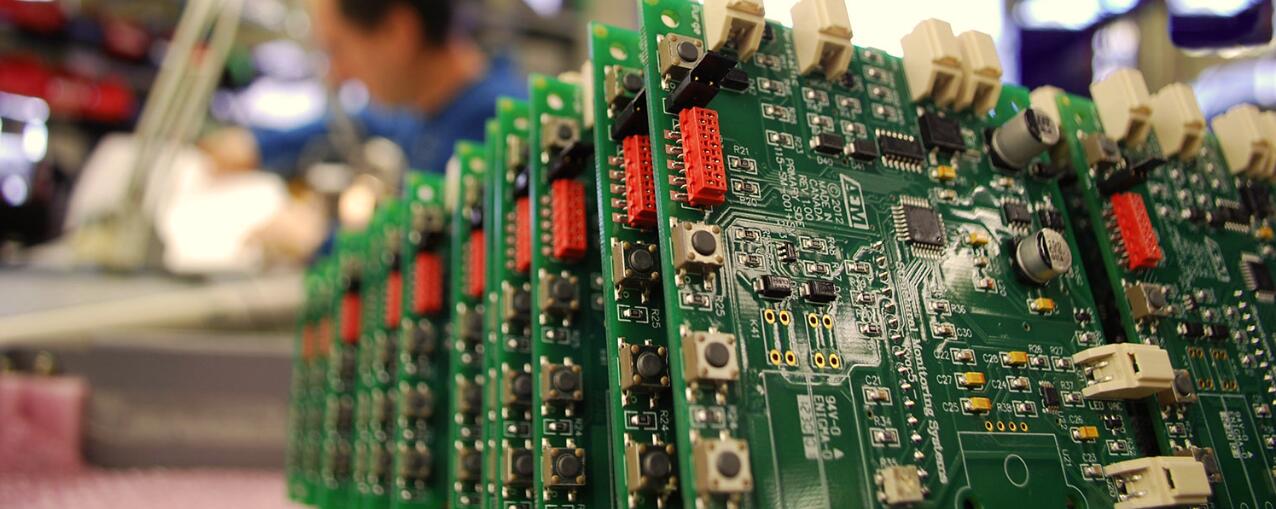

This technology is known as Surface Mount Technology, SMT and SMT components. Virtually all today's equipment that is manufactured commercially uses surface mount technology, SMT, because it offers significant advantages during PCB manufacture, and in view of the size the use of SMT components enables far more electronics to be packed into a much smaller space.

In addition to the size, surface mount technology allows automated PCB assembly and soldering to be used, and this brings significant improvements in reliability as well as enormous savings in cost.

What Are the Advantages of SMT?

More Compact Devices and Increased Design Flexibility

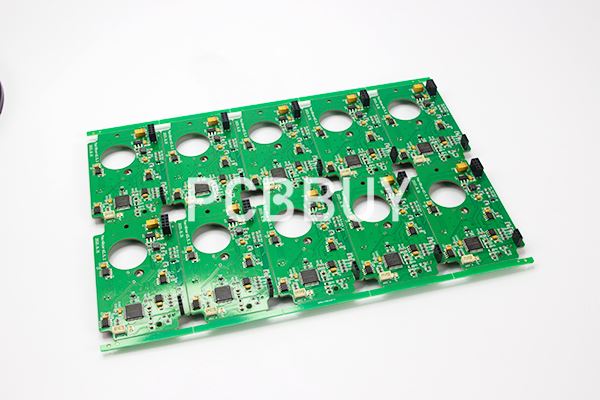

One of the most significant benefits of surface-mount technology is how it supports more compact devices and increases design flexibility. This is because the higher density of the board allows the PCB to take up less space while still providing the same capabilities as a traditional printed circuit board.

As electronic devices get smaller, and the demand for these smaller devices increases, PCBs must also get smaller — surface-mount technology enables this. Manufacturers, designers, and engineers need to keep up with these trends.

Implementing SMT methods to your printed circuit board manufacturing process will lead to more flexibility in design and lighter products. Creating a more lightweight product can expand the possibilities for innovation, reduce shipping costs, and limit the amount of power required to charge and use the device.

Easier Assembly

With surface-mount technology, you eliminate an entire step in the manufacturing and assembly process.

Since you don’t have to connect through-holes by utilizing SMT, the assembly process will be quicker — boards become easier to design, assembly by the manufacturer goes faster, and products get to market quicker.

An easy and efficient assembly process alleviates the number of potential mistakes in producing printed circuit boards.

Lower Costs

It’s not rocket science — when printed circuit boards are smaller, and assembly is easier, costs will be reduced, especially if you partner with the right electronics manufacturer.

With SMT, there are fewer materials to be used, fewer steps in the assembly process, and a better chance to design the next hot electronic device.

What Are the Disadvantages of SMT?

While the benefits of surface-mount technology are profound, there are also disadvantages to note.

First off, the smaller boards and limited lead space make repairs on products created with surface-mount technology difficult. Printed circuit boards can be as little as 0.2” x 0.2”, leaving no room for tools to get close and make repairs.

Having the ability to repair boards and components is important because, without this ability, you’ll likely have to remanufacture, which is costly.

Another common disadvantage to note of surface-mount technology is that this method cannot be used on electronics that have components that produce high amounts of electric heat. This is because the component’s heating can melt the solder, making the printed circuit board useless.

However, the benefits of SMT strongly outweigh the disadvantages in most instances.

Conclusion

Before deciding whether to adopt surface-mount technology for your ONLINE printed circuit boards, it’s important to first determine the requirements needed to produce an end-product successfully. Once you have determined your needs, design a prototype for testing purposes before beginning mass production.

Utilizing SMT will enable you to create smaller devices and simpler designs with quicker assembly and lower costs. Consider implementing this method in your PCB manufacturing process to get a step ahead of the competition.

Industry Category