What is Solder Paste in PCB with 5 Essential Factors for Beginners?

By:PCBBUY 11/15/2021 10:12

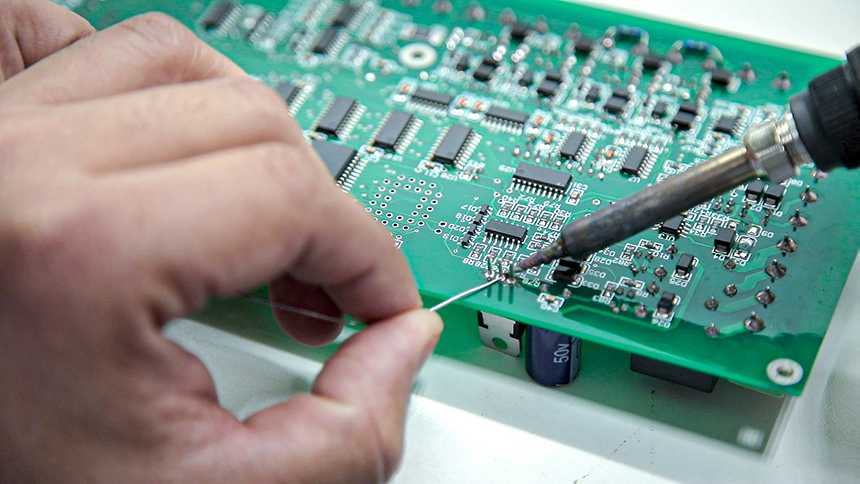

Solder paste is used during the PCB assembly process. The paste is applied on the PCB Board using a solder paste printer, in a process similar to screen printing i.e a stencil is placed over the PCB and then the solder is applied over the board using a solder paste printer. The components are then placed on the board. The viscosity of the paste helps keeps the components in place as the board is moved around or as the board is passed from the component placement section to the reflow oven using a conveyor belt.

In this passage, please check and read the content below for more information about solder paste in PCB. If you are going to learn professional knowledge of solder paste in PCB.

1. What are the main types of solder paste in PCB?

Solder can also be categorized according to the type of flux used:

· Rosin based solder pastes: Rosin based pastes are made of rosin, a natural extract from pine trees. These fluxes can be cleaned if required after the soldering process using a solvent (potentially including chlorofluorocarbons).

· Water soluble flux based solder pastes: Water-soluble fluxes are made up of organic materials and glycol bases. There is a wide variety of cleaning agents for these fluxes.

· No clean solder paste: A no-clean flux is made with resins and various levels of solid residues. No-clean pastes save not only cleaning costs, but also capital expenditures and floor space. Although the no-clean flux based solder pastes sound attractive, they need a very clean assembly environment and may need an inert reflow.

2. What are the applications of solder paste in PCB?

Electronic components were first hand soldered onto circuit boards until the wave soldering process was perfected for the mass production of PCBs. Next came the development of surface mount parts which were smaller than their thru-hole counterparts due to their lack of long leads, and eventually they became the dominant component package type used on circuit boards. The lack of thru-hole pins in surface mount parts, however, forced the development of a new method of soldering in order to hold them in place on the board until the soldering was complete. This new process is known as solder reflow, and it doesn’t use the standard pool of molten solder that the wave process uses. Instead, a sticky solder paste is used to hold the parts in place and solder them as well.

Solder paste is a combination of a powder made up of metal solder particles and sticky flux that has the consistency of putty. The flux not only does its usual job of cleaning the soldering surfaces of impurities and oxidation, but it also provides a temporary adhesive that holds the surface mount components in place. The solder powder used in the paste can vary in its chemical composition with different material types and percentages used depending on the needs of the board being soldered. For instance, solder paste is available in both lead and lead-free versions to satisfy the restriction of hazardous substances (RoHS) directive. Solder paste is also classified by the size of the metal particles that make up the solder powder. These particles must be spherical in shape and can vary in size according to the type standards specified in IPC J-STD 005.

3. How to avoid solder joints of solder paste in PCB?

Solder paste and the solder reflow process is used primarily for surface mount components. There is also the option however of using solder paste instead of wave soldering for thru-hole parts as well. Intrusive reflow solder, known also as pin in paste (PIP) or pin in hole (PIH), saves time and money because there is only one process, the reflow process. As long as the thru-hole components themselves can withstand the reflow oven temperatures, and there is enough clearance around the leads in the holes for the solder paste to be distributed, the reflow process can produce good solid solder joints on plated thru-holes.

Once the board has been prepared with solder paste and the components have been installed, it is ready to be reflowed. The board will travel through a series of industrial convection ovens that regulate different temperature levels to complete the entire reflow process. The board will first be heated to a specific temperature, and then held at that temperature to activate the flux in the solder paste in order to remove the oxides on the soldering surface. Then the board will be heated again for the solder to reflow, after which the board will go through a cooling process to solidify the newly formed solder joints.

4. How to use solder paste in PCB?

Whether you are using the solder paste in mass PCB assembly or prototype PCB assembly, you have to follow certain steps precisely. First, you have to apply the solder paste on the circuit boards. While doing this, you have to make sure that you are applying only to the areas where you will be soldering. There are different methods to achieve this. We have listed two of the most popular methods to apply solder,

Using Stencil

The first method is by using a stencil. The stencil allows you to apply solder paste only in the areas you want. Place the stencil over the board and apply the solder paste through this. You have to make sure that you apply the required amount of solder paste. If you apply too little, the joints will not be strong and break easily. On the other hand, if you apply too much, the joints will become too large. Besides, it will lead to the possibility of shorts between adjacent pads.

5. How to store solder paste?

Before you have used the solder paste, storing it is as simple as placing it in your tool bag. After opening it, however, you need to make sure that you are taking care of the paste properly. It could easily lead to wasted solder since the material can dry up if left opened. Store it in an airtight container so that oxidation cannot occur.

Solder paste (all forms of solder for that matter) do not work well in hot temperatures. Make sure that you are storing it at low temperatures. This keeps the flux lasting longer at a higher quality. It also helps prevent oxidation. Just don’t let the temperature get below freezing.

It's imperative that you do not use your solder paste past the expiration date since the product does degrade even when kept in the best storage conditions.

Industry Category