What is Solderability Test in PCB Manufacturing to Guarantee Quality?

By:PCBBUY 02/01/2023 11:38

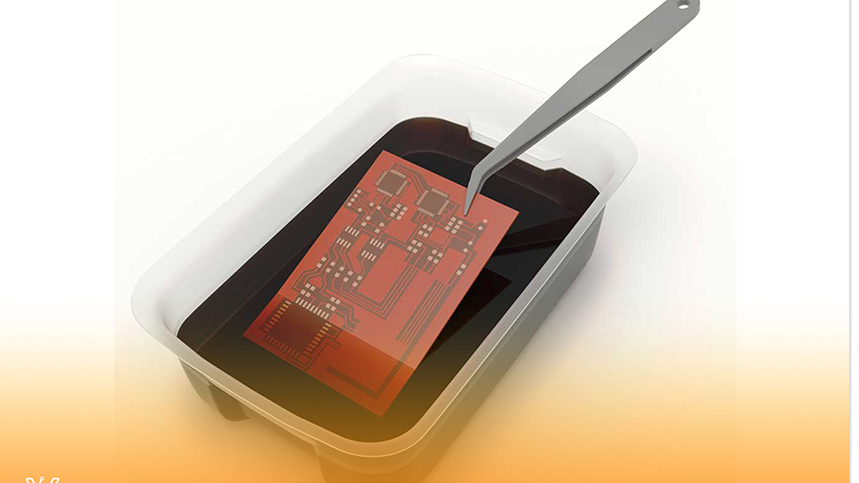

Solderability test on a printed circuit board is critical. If you fail to undertake some tests, then you are inviting trouble. There’s nothing riskier and expensive than rolling out faulty boards to the market. You can avoid such by only undertaking solderability tests. So what’s the importance of the PCB solderability test?

Do you know the importance of PCB solderability test and how to process it? In this passage we are providing all the information of PCB solderability test, if you are searching for more knowledge of PCB solderability test please check and read the content below.

What are the types of PCB solderability test?

Three of the most common solderability testing formats are:

· “Dip and look” method

· The surface mount simulation test

· Wetting balance analysis

1. DIP AND LOOK

Dip and look subjects the leads and terminations to up to 8 hours of steam conditioning, accelerating the aging process. (This is why skin doctors warn against saunas and hot showers!)

Next, testers dip the components into solder using activated rosin flux. Finally, they’re inspected to ensure they meet requirements.

2. SURFACE MOUNT SIMULATION TEST

The surface mount simulation test is available for all surface mount technology (SMT) components, including ones that can’t use other types of PCB testing methods like dip and look.

A specific solder paste is screen-printed onto a ceramic plate. The component then goes into the paste and is subjected to a convection reflow profile.

3. WETTING BALANCE ANALYSIS

Wetting balance analysis also ages the components to measure the wetting forces.

The testers plot the wetting force, starting at negative (nonwet). Solderability is measured as the amount of time it takes for wetting to occur.

What is the equipment of PCB solderability test?

The right tools and equipment are one of those factors which will see you staying relevant in a competitive environment.

Without a doubt, one of the essential tools that you must have is the soldering iron. A soldering iron provides the heat source to melt the solder. But again, the soldering iron doesn’t need to be expensive as such. If you look around, you’ll find some that go for as little as $10.

Besides the soldering iron, other tools that you may need during soldering include the following:

Solder Flux

The Solder Flux acts as a purifying agent, and it purifies the components while closing out extra air to prevent rust. The Solder Flux is one of the essential tools to have at hand when soldering. Manufacturers love it as it goes further to better the dripping individuality of the solder itself.

Solder Paste

Solder Paste joins various leads of chip packages to connection ends of boards. The solder paste appears like a gray putty-like substance. During soldering, the paste joins the multiple charges of chip packages to the connection ends on a PCB.

Solder suckers

Solder suckers also go by the name solder pumps. These mechanical vacuum pumps suck solder away from solder joints. They enable the removal of solder from a joint for components desoldering for rework.

Wire cutters

Even though they tend to be small, wire cutters are convenient tools. You can use the wire cutter to cut off long component legs. Also, you can use these wire cutters to strip the end of the wires. Wire cutters again go by names such as diagonal cutters, flush-cutters, clippers, electronic snippers, and more.

Soldering iron tip cleaner

Soldering tip cleaners are necessary during soldering. They are for cleaning iron tips from any old solder or carbon accumulation. If you want your soldering iron to last for long, then you’ll need soldering iron tip cleaners.

Desoldering Wick

Manufacturers use this to clean the leftovers of solder that remained behind during soldering. A desoldering wick is a finely braided copper wire. The copper wire has a rosin coating flux that can finely remove excess copper.

Circuit board holder

It is the perfect equipment for holding the PCB into place during soldering. Some refer to this equipment as a soldering helping hand and comes in handy when soldering adequate equipment. The circuit board holder fixes the objects at the required angles for soldering.

Industry Category