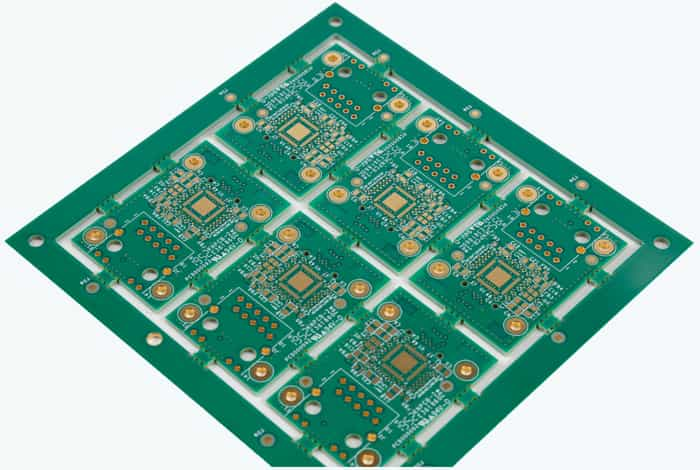

Bare PCB board

By:PCBBUY 05/22/2021 17:08

In PCB terminology, the term “bare board” refers to the state of a PCB before it receives electronic components or through holes. A bare board consists of the PCB’s substrate, metal coating, conductive pathways and patterns. Some industry experts call a bare board a PCB and an assembled board a PCBA.

The simplicity of the blank PCB gives plenty of freedom for engineers and designers to add components as needed. This blank slate provides flexibility and makes the bare PCB boards viable for mass production instead of making them unique for each order.

These PCB boards require more design work than other wiring methods, but the assembly and manufacturing tend to be automated afterward. The automation makes PCB boards the cheapest and most efficient option.

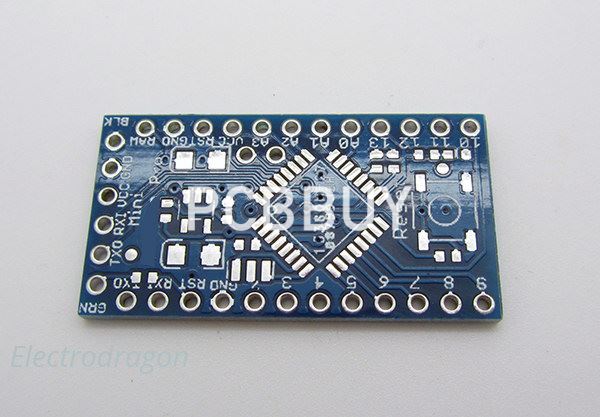

It truly becomes useful when the necessary components are added to it. Becoming a circuit board is the bare PCB board’s end goal and can be extremely versatile if matched with the right components.

Why Use Bare Board Testing?

There are a number of reasons why it’s essential to test the bare boards before adding any additional components. Being the circuit board framework, the PCB board failing after installation can lead to many problems.

While not common, the bare PCB board can already be defective before any components are added. The main issues that pop up are over-etchings, under-etchings, and holes. Even a minor flaw can result in a complete failure.

The increasing demand for multi-layered PCB boards due to their increased component density is another reason to use bare board testing. Once a PCB has been put together into multiple layers, it becomes almost impossible to make repairs in case of failure.

If the PCB board is the circuit board’s skeleton, then the components are the organs and muscles. Components can get expensive and are oftentimes delicate, so having a solid framework can prevent wasting high-end components in the long run.

What Are Types of Bare Board Testing?

How do I know if my PCB is bad? You’ll need to test it in two different ways: electrical and resistance.

Bare board testing considers both the isolation and continuity of the electrical connections. Isolation testing measures connections between two separate connections, while continuity testing checks to make sure there are no open points that could mess with the electrical current.

The most commonly used is the electrical test, while the resistance test isn’t as common. Some companies use a combination of both instead of sticking with one over the other.

The resistance test sends an electric current through the conductor to measure the resistance to the flow. Longer or thinner connections results in much more resistance than shorter or thicker ones.

Large Manufacturer Testing

A printed circuit board manufacturer will likely use the pinned fixture test, otherwise known as the “bed of nails.” This test uses spring-loaded pins to test every connective surface on the PCB board at once.

The pinned fixture test is extremely efficient and only takes a handful of seconds to finish. The main downsides are the high expenses and the lack of flexibility. If a different PCB design is required, a whole new fixture and an array of pins are required.

Small Manufacturer Testing

What is bare PCB board testing like for smaller companies? They typically use the flying probe test. Two robotic arms with poles use a software program to test the board’s connections.

It takes much longer to complete but is more affordable and flexible than the pinned fixture test. Switching to a different design is as simple as uploading new software.

What Are Benefits of Bare Board Testing?

There are numerous benefits to bare board testing and no real disadvantages to doing so. This small extra step in the manufacturing process can save much heartache further down the line. The slight investment early on can save thousands of dollars in repair and replacement costs.

Bare board testing helps to identify issues early on in the manufacturing process. Finding the issue early on means that it’s far easier to find the problem’s source and fix the problem at its roots.

Catching an issue late in the process makes it much harder to find the source. Once the PCB board is covered in components, there’s no telling what would be responsible for an issue. Early testing helps remove a big piece from the equation for troubleshooting.

The testing also ends up streamlining the entire process. If issues are caught and fixed in the prototyping stage, then the later production phases can move on unhindered.

Industry Category