Flexible PCB

By:PCBBUY 05/10/2021 18:20

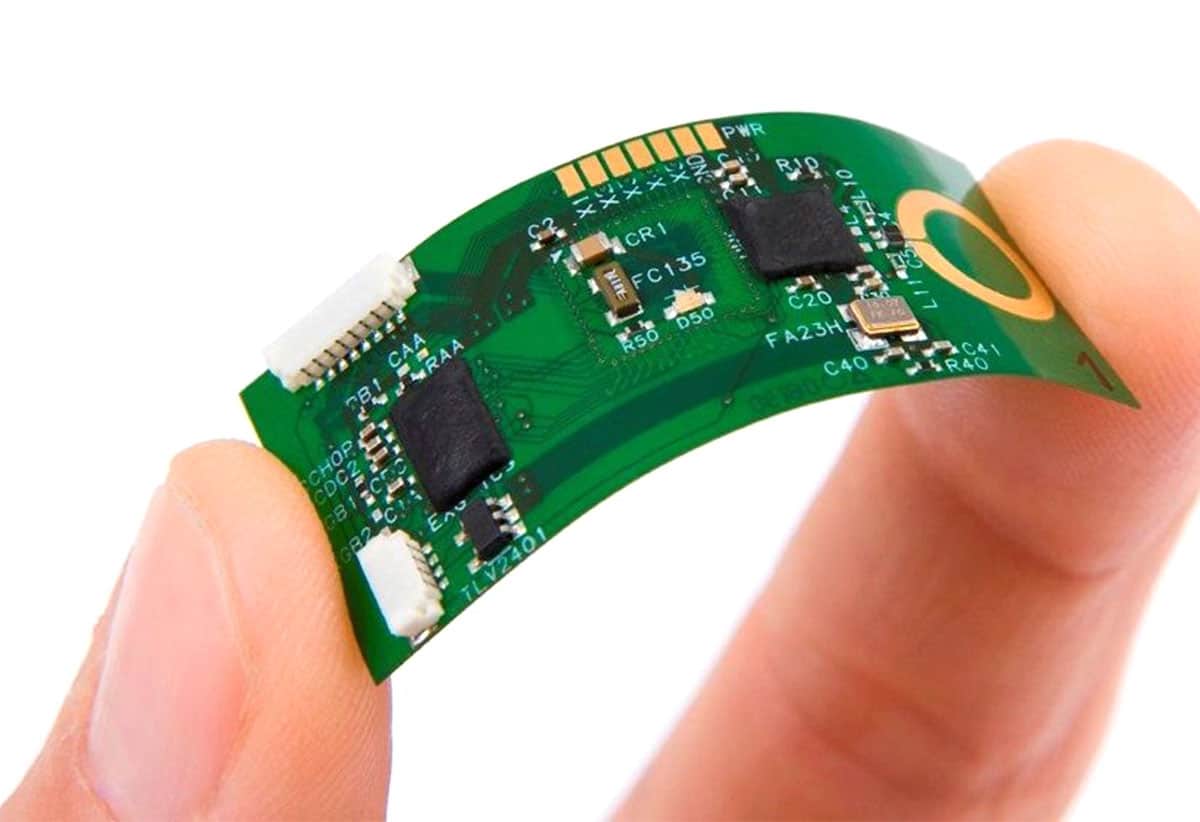

The flexible PCBs feature a combination of several printed circuits as well as components that are positioned on a flexible substrate. These circuit boards are also known as flex circuit boards, flex PCBs, flex circuits, or flexible printed circuits. These printed circuit boards are designed using the same components as rigid printed circuit boards. However, the only difference is the board is made such that it flexes to a desired shape during the application.

Flexible PCB is continuously growing, with applications in the main electronics sectors, such as consumer, automotive, electro-medical devices, wearable, telecommunications and aerospace. The introduction of flexible PCBs has revolutionized the legacy electrical interconnection techniques, traditionally used to connect multiple parts of the same circuit or of multiple electronic devices.

Thanks to the flexible nature of the connection, its compactness, and the high density of electrical connections that can be achieved, the solution based on flexible PCBs allows to obtain a considerable reduction of space, weight and costs compared to an equivalent solution based on rigid PCBs. And today we will focus on the detailed knowledge of flexible PCB.

What materials are used in flexible PCB?

There are single-sided, double-sided and multi-layered forms in flexible circuits, each of which requires a variety of materials to function. The materials that MCL works with include both custom and branded materials from trusted suppliers. A few of the materials you can choose from include these:

Adhesives

The requirements of an application, as well as the dimensions of the conductor involved, tend to guide adhesive selection. Some of the most popular adhesives on the market include acrylics, epoxies, pressure-sensitive adhesives (PSAs) and adhesive-free base materials.

Finishes

A few of the finishes you can choose from include carbon, gold, hard nickel, tin, silver and even organic materials. Each option creates different results and is best suited to different applications, so be sure to consult with MCL on the best finish for your needs.

Insulators

Insulators are a must, and you’ll need the right insulation material to match your PCB. The wrong insulator might result in PCB failure in the long term. PCB insulators combine coverlay materials and flexible substrates in a variety of form factors and thicknesses.

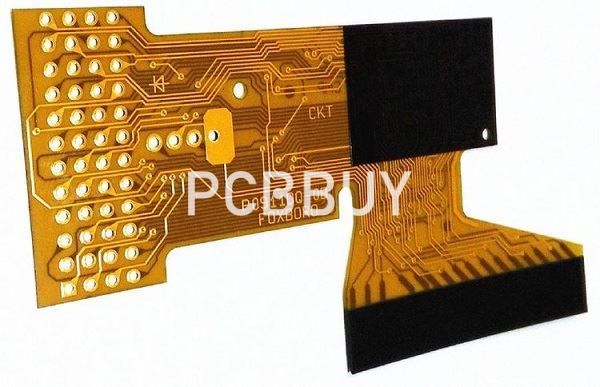

What are the types of flexible of PCB?

There are several types of flexible circuits that can be designed according to the needs of the customer. Given below are a few basic types:

What is Single Sided Flex?

It comprises a conductive layer of copper on one side of the PCB. Single sided circuit PCBs are ideal for dynamic applications, or equipment that require circuits with high levels of flexibility. They are known for their immense cost-effectiveness and ease of assembly.

What is Double Sided Flex?

An expansion on the singled sided flex PCB, the double sided flex comprises a conductive layer of copper on both sides of the PCB. Generally, the copper layers are connected to each other by Plate Through Holes (PTH) or vias. These holes or vias create an active circuitry between the layers.

What is Multi-Layer Flex?

As the name suggests, multi-layer flex circuits comprise more than two copper conductors. In a typical circuit, you will find up to 10 conductive layers. Like the double sided flex circuit boards, multi-layer PCBs are interconnected by PTH holes or Vias.

What is Rigid Flex Circuit Boards?

This circuit is a combination of rigid and flexible circuits. The flexible layers are integrated with the rigid layers, and the PCB is assembled using PTH technology. The advantage of this type of circuit is that the combination of rigid and flex layers creates small interconnect areas, which reduces the chances of PCB failure in an application.

What is High Density Interconnects?

Also known as HDI, high density interconnects are flex circuit boards, which are designed to provide more technical solutions in terms of design, layout, and construction. Each HDI includes extremely dense flex circuitry with precise features and microvias.

Industry Category