Rigid PCB

By:PCBBUY 05/19/2021 18:05

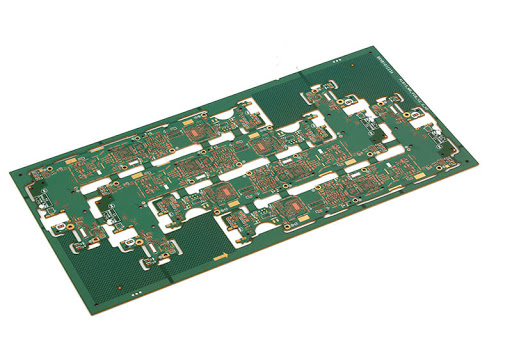

Rigid PCB, as a kind of PCB, is the largest number in PCB manufacturing process. It is made of solid substrate material, which can effectively prevent the distortion of the circuit board. Rigid circuit boards are very popular largely due to their low cost. In conventional electronics, and particularly in consumer electronics, with greater space availability, manufacturers can save significantly by using rigid circuit boards.

Perhaps the most common rigid PCB board is the computer motherboard. The motherboard is a multi-layer PCB designed to distribute power from the power supply while allowing communication between all components of the computer, such as CPU, GPU, and RAM. Rigid PCB can be used in any position where the PCB itself needs to be set to a shape and maintained during the remaining life of the equipment. Rigid PCBs can be anything from simple single-layer PCBs to eight or ten-layer multi-layer PCBs.

In this passage, we will talk about the knowledge of rigid PCB and please check the content below for more information.

How is rigid PCB manufactured?

Rigid PCB is made up of different layers that are joined together using adhesive and heat, providing a solid shape to board material. Following layers are used to develop a rigid PCB.

Substrate Layer - rigid PCB material

Substrate layer, also referred base material, is made of fiber glass. The FR4 is mostly used as a substrate material which a most common fiber glass that provides rigidity and stiffness to the board. Phenilcs and epoxies are also used as a base material but they are not as good as FR4, however, they are less expensive and feature unique bad smell. Decomposition temperature of phenolics is too low that results in delamination of the layer if solder is placed for long duration of time.

Copper Layer

On the top of substrate layer, there resides a copper foil which is laminated on the board with the help of added amount heat and adhesive. In common use, both sides of the board are laminated with copper, however, some cheap electronics come with only one layer of copper material on the board. Different boards come with different thickness which is described in ounces per square foot.

Solder Mask Layer

Solder Mask Layer houses above the copper layer.

This layer is added on the board to add insulation on the copper layer in order to avoid any damage in case any conduction material is touched with the copper layer.

Silkscreen Layer

Silkscreen layer is located above solder mask layer. It is used to add characters or symbol on the board that provide better understanding of the board. White color is mostly used for silkscreen but other colors are also available including grey, red black and yellow.

What are factors that affect the cost of rigid PCB?

There are three main factors that impact the cost of rigid-flex PCB:

Materials: The raw materials used to manufacture rigid-flex PCBs tend to cost more than traditional PCB materials. While these boards use common materials such as copper foil, they also incorporate no flow prepregs, flexible copper-clad laminates and thicker polyimide films.

Assembly: Because there are separate components and complex steps required, the assembly process costs more.

Manufacturing yield: To manufacture rigid-flex boards, specialized equipment and software tools are needed, which impacts the final cost.

How to reduce the cost of rigid PCB?

There are various ways to lower the cost of your rigid-flex PCB, including:

Minimize the amount of circuit layers

Choose materials carefully

Reduce the thickness of the materials

Simplify the configuration

Tailor the design process

Industry Category