Solderability test

By:PCBBUY 06/26/2021 17:09

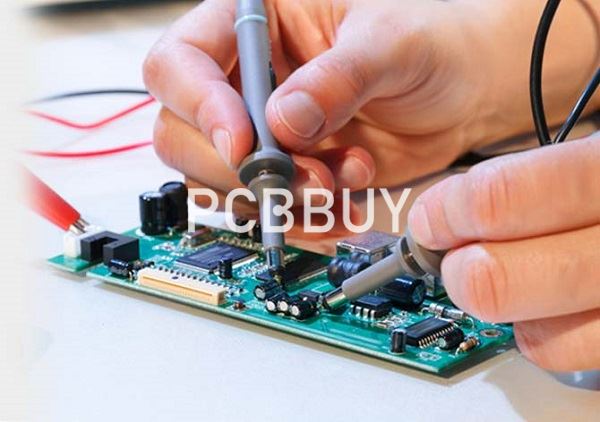

The solderability test determines the solderability of terminals and leads through a specific soldering operation. Solderability measures how perfect or imperfect the metal is wet by molten solder to secure all connections.

Evaluating solderability tells your PCB tester whether the attached parts, such as terminations and leads, can withstand high temperatures. High temperatures may occur during welding. Tests also determine whether these components’ storage will adversely affect their ability to solder to circuit boards.

Understanding matters to do with PCB solderability tests can significantly minimize board failures while improving the product’s final quality. In short, solderability is the molten solder’s ability to maintain a uniform liquid state unbroken and even during the soldering process.

If you want to order PCB product, please check and custom your order online.

What are the types of solderability test?

There are three primary types of solderability tests. They include the following:

Immersion approach

This method also goes by the name Dip and Look. The “immersion” approach subjects the termination and leads up to 8 hours of steam conditioning. The steam conditioning is over; what follows is the dipping of components’ termination into the solder. This factor accelerates the aging process. Finally, inspection follows to ensure that they meet the required standards.

The surface mount simulation test

It is another primary type of solderability test. It’s available for all SMT components, such as those that aren’t compatible with other types of PCB test methods, such as the “immersion” approach.

Wet balance analysis

Lastly, there’s wet balance analysis, a type of test that ages the circuit board components. Here, the testers get to plot the wetting force, beginning at negative (non-wet).

What is the importance of solderability test?

Solderability test on a printed circuit board is critical. If you fail to undertake some tests, then you are inviting trouble. There’s nothing riskier and expensive than rolling out faulty boards to the market. You can avoid such by only undertaking solderability tests. So what’s the importance of the PCB solderability test? Here they are:

Evaluation of PCB coating, solder and flux

Solderability tests ensure that you assess the quality of your coating, solder, and flux before introducing them to the market. Having great coating solder and flux will give the end-user ample time during repairs while also ensuring the product is long-lasting.

Perform quality control

Solderability tests confirm that there’s quality control of the circuit boards that PCB manufacturers make. By doing so, manufacturers ensure that they produce high-quality products that meet customer satisfaction.

Reduce assembly problems, including misapplication of solder mask

During assembly, problems are likely to occur. Some of the typical assembly problems include insufficient copper-to-edge clearance and lousy soldering. Others include the misapplication of the mask, the solder mask, and non-wetting challenges. Fortunately, though, such isn’t the case with solderability tests. Manufacturers that get to undertake solderability tests will realize reduced assembly problems, an aspect that gives them an edge over their competitors.

Improve the possibility of reliable solder joints

In the field of electronics, the quality of the solder matters a lot. Therefore, with poor solder joints, then the transmission of signals from one point of the board to the next would almost be impossible.

Reliability in solder joints is necessary for the proper functionality of the whole board. These tests point out faulty solder joints that need attention, thereby bringing out the possibility of having reliable solder joints.

Verify secure storage

It’s essential to store these circuits within the shortest time possible as means of reducing possible damages. Solderability tests are crucial here because they help verify that suppliers meet solderability requirements. They help in proving that storage conditions don’t degrade solderability. With solderability tests, it’s easy to estimate some of the long-term effects that accompany storage.

Industry Category