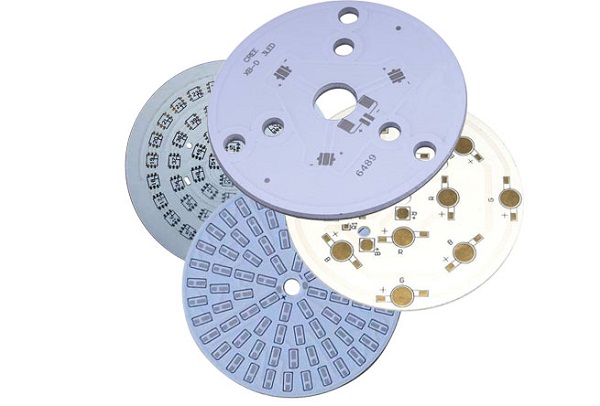

What is the Standard of Aluminum PCB Thermal Conductivity?

By:PCBBUY 01/19/2022 10:05

Aluminum is one alternative material that can be used in the core of a PCB, commonly referred to using the misnomer “aluminum PCN”. Using aluminum as the metal core in a PCB allows it to easily dissipate heat away from active components thanks to its high thermal conductivity. The high thermal conductivity of aluminum or another metal in the core of a PCB allow heat to be distributed more uniformly throughout a board.

In this passage we are providing all the information of aluminum PCB. If you are searching for the knowledge, please check and read the passage below for more.

What are the benefits of aluminum PCB?

Environmentally Friendly

Aluminum is non-toxic and recyclable. Manufacturing with aluminum is also conducive to conserving energy due to its ease of assembly. For printed circuit board suppliers, using this metal helps maintain the health of our planet.

Heat dissipation

High temperatures can cause severe damage to electronics, so it is wise to use a material that can help dissipate heat. Aluminum can actually transfer heat away from vital components, thus minimizing the harmful effect it could have on the circuit board.

Higher durability

Aluminum provides strength and durability to a product that ceramic or fiberglass bases cannot. Aluminum is a sturdy base material that can reduce accidental breakage during manufacturing, handling, and everyday use.

Lightweight

For its incredible durability, aluminum is a surprisingly lightweight metal. Aluminum adds strength and resilience without adding on any additional weight.

What is standard of aluminum PCB thermal conductivity?

The thermal conductivity of Aluminum Core PCB, is an aluminum substrate thermal performance parameter, which is one of the three major criteria for measuring the quality (the other two properties are the thermal resistance value and the withstand voltage value ).

The thermal conductivity of the aluminum substrate can be tested after lamination. At present, the high thermal conductivity is generally ceramics, copper, etc. However, the cost of ceramics and copper is high. So the most widely used is the aluminum substrate, which is a unique metal-based copper-clad aluminum substrate with good thermal conductivity, electrical insulation and mechanical properties.

Heat dissipation

The multilayer pcb board has high density and high power, It is difficult to dissipate heat.

The conventional PCB substrates, such as FR4, CEM3, are thermal poor conductors. The local heating of the electronic equipment is not solved, resulting in high temperature and the electronic components will burn out. But the aluminum substrate can solve this heat dissipation problem.

Thermal expansion

Thermal expansion and contraction are the common nature of matter, and the thermal expansion coefficients of different substances are different. The aluminum-based PCB can effectively solve the heat dissipation problem, thereby alleviating the thermal expansion and contraction of different materials on the printed board, and improving the durability and reliability of the whole machine and the electronic equipment. In particular, it solves the problem of thermal expansion and contraction of SMT (Surface Mount Technology).

Dimensional stability

Aluminum core PCB is clearly much more stable than printed boards of insulating materials, which is heated from 30 ° C to 140 ~ 150 ° C, and the dimensional change is 2.5 ~ 3.0%.

How to process the thermal management of aluminum PCB?

In LED applications, especially high-power LED lights, it’s known that LED SMD converts the greater part of the current into heat rather than light itself. The PCB size is designed towards miniaturization, and the heat output per unit area increased in this situation. That’s to say, more and more heat is transferred to a smaller and smaller surface with or without PTH. Too much heat can’t be dissipated, the parts on the PCB assembly have to work under high temperature environment. When work in a certain time, the parts are easier to be damaged, then the products lifespan will be shorter compared to those products with high thermal conductivity MCPCBs. The consideration of sufficient heat management seems very important in PCB design stage.

Design / construction of PCB

Try to separate high power and signal conductors, enlarge the tracks of heavy currents, add copper thickness and add more thermal vias. Compared with the PCB design without these considerations, your design can do thermal dissipation much more and quicker.

Heavy Copper PCBs

Copper itself has good thermal conductivity. Heavy copper (2oz, 3oz, max 10oz) can improve the heat dissipation.

Check our Heavy Copper PCB to know more about the thermal simulation of heavy copper.

Thermal Via Array

Thermal vias will be helpful to achieve a significant reduction in thermal resistance, and improve thermal dissipation.

Industry Category