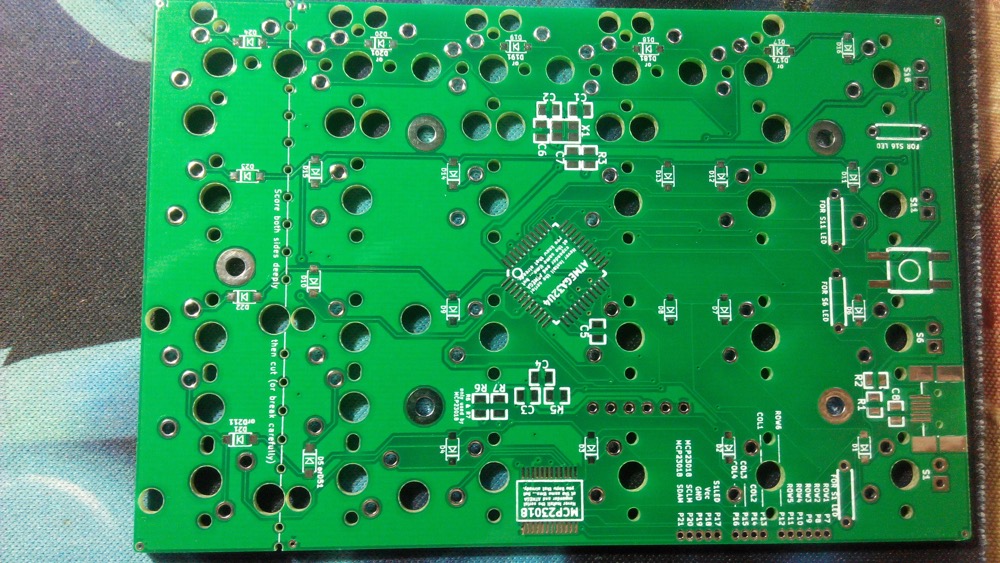

What is the reason for the pinholes on the circuit board

By:PCBBUY 12/15/2023 09:25

The formation of pinholes in circuit boards can stem from various factors, mainly including the following:

Discrepancy in Component Pin and Hole Sizes: Inconsistency between component pins and hole sizes prevents proper filling of solder in the PCB insert hole, resulting in pinholes. Non-Conformance of PCB Hole Copper Thickness and Roughness: Insufficient copper thickness or roughness in PCB holes impedes proper soldering, leading to pinhole formation. Moisture Exposure of the Circuit Board: Moisture in the circuit board generates gas during reflow, causing pinhole formation. Incomplete Solder Pad: Incomplete solder pads hinder the filling of solder during the soldering process, creating pinholes. Oxidation or Burr Around the Hole: Oxidation or burrs around the hole cause oxidation or contamination of component pins due to inadequate pretreatment, resulting in pinholes. Factors such as contaminants, gases from board-to-component footprints, and improper operation of automatic insertion machines or part-forming machines contribute to the occurrence of pinholes in circuit boards. Low Preheat Temperature or Excessive Chain Speed: Inadequate preheat temperature or rapid chain speed results in incomplete evaporation of moisture or solvents, leading to pinholes. Excessive Solder Temperature or Flow: High solder temperature or excessive flow might result in pinhole formation. Inadequate Flux Deoxidation or Poor Wetting Characteristics: Flux with insufficient deoxidation ability or poor wetting characteristics can also lead to pinhole formation.

To address pinhole issues in circuit boards, several methods can be employed:

Inspect and replace questionable materials or components.

For moisture-exposed boards, use an oven to bake them before soldering.

Increase preheating temperature, decrease chain speed to enhance preheating and solder wetting duration.

Lower solder temperature without compromising quality to reduce solder flow.

Use flux with stronger deoxidation capabilities and better wetting properties.

Inspect solder alloy composition in the solder bath for compliance.

In summary, resolving pinhole issues in circuit boards requires a multi-faceted approach, including aligning component pin and hole sizes, controlling PCB hole copper thickness and roughness, moisture prevention in circuit boards, ensuring solder pad integrity, preventing oxidation or contamination of component pins, and selecting appropriate flux. Additionally, attention to correct equipment operation and adjustment of process parameters during production ensures high-quality circuit boards.

Industry Category