Which Part is Important to Choose a PCB Manufacturer?

By:PCBBUY 09/30/2024 15:10

Selecting the right PCB manufacturer is crucial for ensuring the success of any electronic project. With the growing complexity of electronic devices, it’s essential to consider multiple factors when choosing a manufacturer. This article explores the key components to consider when selecting a PCB manufacturer, including quality, technology, communication, and cost.

1. Understanding PCB Manufacturing

1.1 What is a PCB?

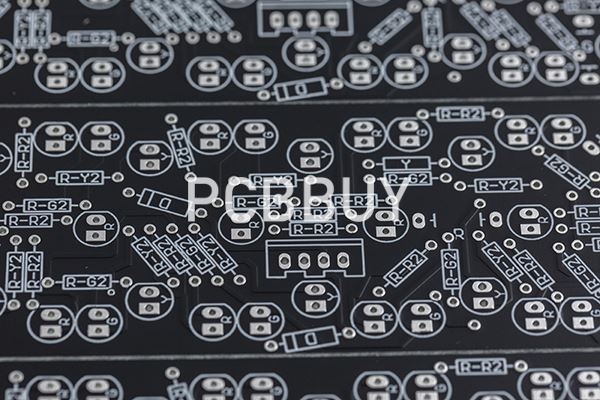

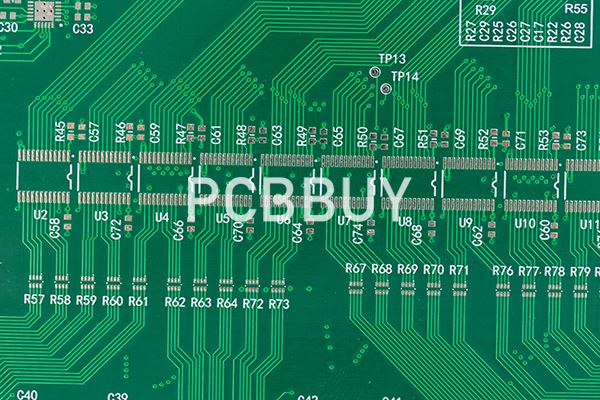

A Printed Circuit Board (PCB) is a foundational component in most electronic devices, providing mechanical support and electrical connections for electronic components. PCBs can vary in complexity from simple single-sided boards to intricate multi-layer designs.

1.2 PCB Manufacturing Process

The PCB manufacturing process involves several key steps, including:

1. Design and Layout: Using CAD software to create the PCB design.

2. Material Selection: Choosing appropriate materials, such as FR-4 or Rogers.

3. Etching: Removing excess copper to create the desired circuit patterns.

4. Drilling: Creating holes for components and vias.

5. Plating and Finishing: Applying surface finishes to improve solderability and protect the copper.

Chemical Equation for Etching Process

The etching process often involves the use of copper chloride, where the reaction can be represented as follows:

Cu2+ + 2Cl- →CuCl2

2. Key Factors to Consider When Choosing a PCB Manufacturer

2.1 Quality Assurance

Quality is paramount in PCB manufacturing. Key aspects to evaluate include:

Certifications: Look for manufacturers with certifications such as ISO 9001, IPC-A-600, or IPC-A-610.

Testing Capabilities: Ensure the manufacturer offers testing services such as Automated Optical Inspection (AOI) and X-ray inspection.

Table 1: Common PCB Certifications

|

Certification |

Description |

|

ISO 9001 |

Quality management standards |

|

IPC-A-600 |

Acceptability of printed boards |

|

IPC-A-610 |

Acceptability of electronic assemblies |

2.2 Technology and Capabilities

Different projects require different technologies. Important considerations include:

Layer Count: Ensure the manufacturer can handle the required number of layers.

Special Features: Check for capabilities like HDI, blind/buried vias, and impedance control.

2.3 Communication and Support

Effective communication is critical for project success. Factors to consider:

Responsiveness: How quickly do they respond to inquiries?

Technical Support: Does the manufacturer provide technical assistance during the design phase?

3. Cost Considerations

3.1 Pricing Structure

Understanding the pricing structure is essential for budgeting. Key components of pricing include:

Material Costs: Prices for different substrates and finishes.

Labor Costs: Costs associated with the manufacturing process.

Setup Fees: Initial costs for tooling and setup.

3.2 Value vs. Cost

It’s important to consider the value provided rather than just the cost. A lower-priced manufacturer may compromise on quality, leading to higher costs in the long run.

4. Lead Times and Production Capacity

4.1 Understanding Lead Times

Lead times can significantly impact project timelines. Factors influencing lead times include:

Manufacturing Capacity: The manufacturer’s ability to handle your order volume.

Complexity of Design: More complex designs typically require longer lead times.

4.2 Flexibility

A good PCB manufacturer should be flexible in accommodating changes to design or order quantity. This is essential for adapting to project requirements.

5. Supplier Reliability

5.1 Reputation

Researching the manufacturer’s reputation can provide insights into reliability. Consider:

Customer Reviews: Look for testimonials and case studies.

Industry Experience: Manufacturers with extensive experience in your industry may better understand your needs.

5.2 Location

The location of the manufacturer can affect shipping times and costs. Consider whether you prefer local manufacturers for faster communication and shipping.

6. Future Trends in PCB Manufacturing

6.1 Advancements in Technology

The PCB industry is continuously evolving. Emerging trends include:

Green Manufacturing: Increasing focus on environmentally friendly processes.

Smart PCBs: Integration of sensors and IoT capabilities into PCBs.

6.2 Industry Standards

Stay updated on industry standards and certifications, as these are crucial for ensuring quality and compliance.

Conclusion

Choosing the right PCB manufacturer involves careful consideration of several factors, including quality, technology, communication, and cost. By evaluating these components, you can make an informed decision that will lead to the successful execution of your electronic projects. A reliable manufacturer will not only meet your current needs but also adapt to future advancements in technology and market demands.

References

1. IPC. (2021). "PCB Design Standards." IPC.

2. ISO. (2022). "ISO 9001: Quality Management Systems." ISO.

3. Rogers Corporation. (2023). "High-Frequency PCB Materials." Rogers Corporation.

4. Friedman, A. (2024). "The Future of PCB Manufacturing." *Journal of Electronics*.

5. Hwang, J. (2022). "Cost Analysis in PCB Manufacturing." *International Journal of Electronics*.

Industry Category