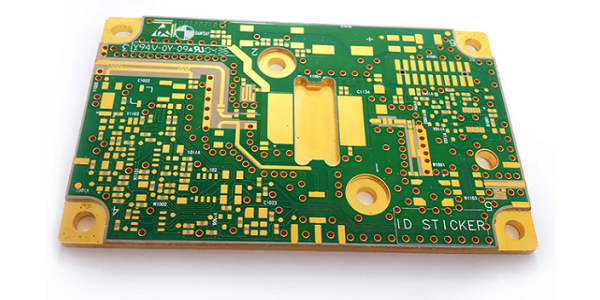

Why Rapid PCB Prototyping Is Popular in Manufacturing Industry with Consideration?

By:PCBBUY 02/24/2023 18:13

In the past, turning a product idea into a finished item took a lot of time and work. But with 3D printing, this process has gotten much faster. It cuts down the time needed to make a prototype, which also makes it easy to change the design if you need to.

When selecting a rapid PCB prototyping manufacturer, there are a few key features and services that you should expect. How to find in a Rapid PCB Prototyping Partner?

Instant Quotes

If the vendor can’t get you a quote for your prototype in seconds, don’t expect anything else about the process to be quick. You should be able to find out how much your project will cost right away.

Online Management App

Rapid PCB prototyping works because of cloud apps combined with backend manufacturing processes. Look for a tool that has an easy-to-use portal—one where you can order, get quotes, manage changes, and track your project all in one place.

In House Parts

Many modern electronics component makers keep common parts in stock. This helps lower costs because they can buy these parts in large quantities and pass the savings on to you.

Onshore Manufacturing

There are good reasons to choose a partner that makes your prototype in China—speed is a big one. If your prototype has to be shipped from another country, rapid prototyping becomes hard.

In-House Assembly

Not all rapid PCB prototyping services operate their own assembly line, but instead send your designs to a 3rd party manufacturing service. Watch out for outsourced PCB assembly as it adds additional points of failure which may delay or kill your project.

Ability to work with different materials

Materials are added layer by layer in prototyping, and their connection keeps the circuit board from restricting the circuits. With modern tech, 3D circuit board manufacturing only uses materials that are necessary for production—no waste.

Product Testing

Testing 3D PCB prototypes thoroughly is a big advantage. This tech lets you find expensive mistakes before your product reaches the mass production stage. You can catch errors early and fix them in time. Also, since development takes less time, designers have more freedom to break “design for manufacturing” rules that are common in traditional (subtractive) PCB making.

Benefits of Rapid PCB Prototyping

1. Cost Savings and Better Budget Control

A major plus of this tech is that it helps optimize costs. 3D printers are now much more affordable—they’re no longer just for big companies. Rapid prototyping is a huge help for startups: if you have a small budget and need to show a “minimum viable product” (a basic version of your product) to potential investors, this is perfect. It lets you turn your idea into a real product fast, so you can “fail fast” (test and fix quickly) and improve your product before final production.

2. Faster PCB Manufacturing

As we said earlier, turning an idea into a finished product used to take lots of time and effort. 3D printing speeds this up a lot—it cuts the time to make a prototype significantly. This also means you won’t get any bad surprises later: once your prototype is done, you can check if the product works well or if you need to make changes.

Why Local PCB Contract Manufacturers Are a Good Choice?

Local PCB contract manufacturers (CMs) have unique advantages, especially when you need quick, reliable results. Here’s what makes them stand out:

1. Easy Location Benefits

Since they’re local, you don’t have to worry about time zone differences or shipping problems that come with overseas manufacturers (like when making medical equipment). You can talk to the local CM quickly and clearly about what you need, so your project can start and finish as fast as possible.

2. More Capabilities

Local CMs don’t just build circuit boards—they often offer other useful services too. Many have in-house capabilities to make cables, wire harnesses, and even assemble “boxes” (the outer casings of devices). This means your project is built exactly to your specs, and it gets finished faster because everything is under one roof.

3. Expert Engineering Support

Most local CMs have big engineering teams. These experts will help you check if your design works before production, and they can even help you improve the design if needed. They know all the electrical and mechanical details of PCB making, so they’ll make sure your product is built correctly.

4. Easy Access to Components

Local CMs have large networks of component makers and vendors. This means they can get the parts you need for your project easily. Plus, they can look at the parts you plan to use and suggest better alternatives—ones that work better, cost less, or arrive faster.

5. Fast Turnaround

Local CMs specialize in making small batches of many different types of projects. They’re used to working quickly, so they can respond fast to your needs while still making a high-quality product.

Industry Category