Why We Need to Calculate PCB Assembly Cost?

By:PCBBUY 10/26/2024 16:35

Understanding the cost of PCB assembly is crucial for businesses involved in electronics manufacturing. It impacts pricing strategies, profit margins, and overall project feasibility. This article delves into the reasons for calculating PCB assembly costs, the components that contribute to these costs, and methodologies for achieving accurate estimations.

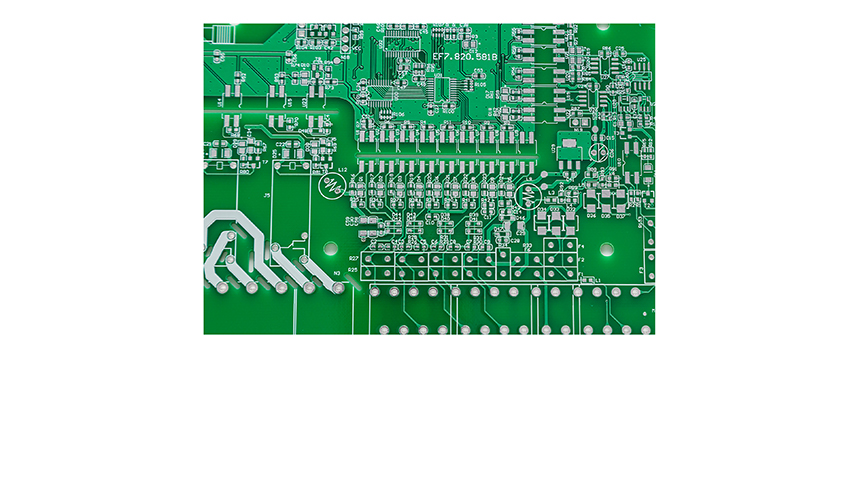

Introduction to PCB Assembly Cost

PCB (Printed Circuit Board) assembly involves the process of soldering components onto the PCB to create functional electronic devices. The cost of this assembly can vary significantly based on several factors, including component types, labor, manufacturing processes, and overhead costs. Accurately calculating these costs helps manufacturers to optimize production, streamline budgeting, and improve financial planning.

What Is the Importance of Cost Calculation?

1. Budgeting and Financial Planning

Accurately calculating the costs associated with PCB assembly allows manufacturers to create realistic budgets for their projects. Without a detailed understanding of costs, companies risk overspending, which can jeopardize project success. A well-defined budget helps allocate resources efficiently and ensures that financial objectives are met.

2. Pricing Strategy Development

Understanding the costs involved in PCB assembly enables manufacturers to set competitive pricing for their products. This is essential for gaining market share while ensuring profitability. A detailed cost breakdown allows companies to identify areas where they can reduce expenses without compromising quality.

3. Profit Margin Analysis

Calculating PCB assembly costs allows businesses to analyze their profit margins accurately. By understanding how much each component of the assembly process costs, manufacturers can identify opportunities to increase profitability. This may involve negotiating better prices for components or improving production efficiencies.

What Are Components of PCB Assembly Cost?

Material Costs

Material costs are a significant component of PCB assembly expenses. They include the cost of the PCB itself and all electronic components required for the assembly. Key factors influencing material costs include:

Type of PCB: Different types of PCBs (single-sided, double-sided, multi-layer) have varying costs associated with manufacturing.

Components: The choice of electronic components, such as resistors, capacitors, and integrated circuits, can significantly impact costs. High-performance or specialty components often come at a premium.

Labor Costs

Labor costs encompass the wages of the personnel involved in the assembly process, including:

Assembly Technicians: The cost of skilled workers who solder and assemble components on the PCB.

Quality Control Personnel: Labor costs related to inspection and testing to ensure the assembled PCBs meet quality standards.

What Are the Manufacturing Overheads?

Manufacturing overheads include indirect costs that support the PCB assembly process, such as:

Facility Costs: Rent, utilities, and maintenance of manufacturing facilities.

Equipment Depreciation: Costs associated with the wear and tear of machinery used in the assembly process.

What Are the Methodologies for Cost Calculation?

Direct Costing Method

The direct costing method involves identifying and summing all direct costs associated with PCB assembly, including material and labor costs. This straightforward approach is suitable for businesses that require quick estimations for project bids.

Activity-Based Costing (ABC)

Activity-Based Costing (ABC) provides a more detailed approach by allocating costs based on specific activities involved in the assembly process. This method allows businesses to understand how different activities contribute to overall costs and identify inefficiencies.

Example Calculation

To illustrate the importance of accurate PCB assembly cost calculation, consider a hypothetical project:

|

Component |

Quantity |

Unit Cost |

Total Cost |

|

PCB (Double-sided) |

100 |

$5.00 |

$500.00 |

|

Resistors |

1000 |

$0.10 |

$100.00 |

|

Capacitors |

500 |

$0.20 |

$100.00 |

|

Integrated Circuits |

200 |

$1.50 |

$300.00 |

|

Labor (Technician) |

50 hours |

$25.00 |

$1,250.00 |

|

Quality Control |

10 hours |

$30.00 |

$300.00 |

|

Total Assembly Cost |

$2,650.00 |

In this example, the total assembly cost is calculated at $2,650. Understanding this cost helps determine the pricing strategy for the final product.

Conclusion

Calculating PCB assembly costs is essential for efficient management of electronic manufacturing projects. It enables businesses to create accurate budgets, develop competitive pricing strategies, and analyze profit margins effectively. By understanding the various components contributing to assembly costs and utilizing methodologies such as direct costing and activity-based costing, manufacturers can make informed decisions that enhance profitability and operational efficiency.

References

- IPC-2221, "Generic Standard on Printed Board Design."

- K. S. Lee, "PCB Design for Real-World EMI Control," Wiley, 2008.

- D. L. Pritchett, "Cost Management: A Strategic Emphasis," Cengage Learning, 2010.

Industry Category