what is clothes dryer pcb?

By:PCBBUY 01/31/2024 23:50

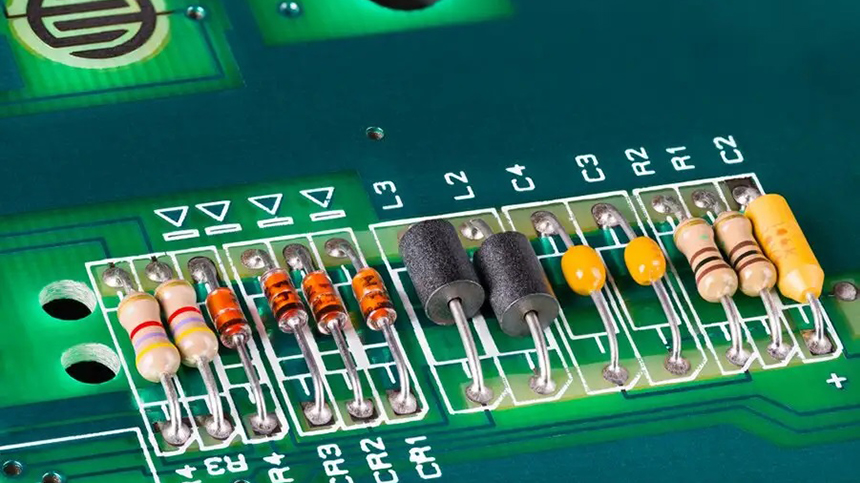

The core components of a clothes dryer PCB typically include a microprocessor, power circuit, motor drive circuit, temperature sensor, humidity sensor, etc. Its working principle involves the microprocessor processing input signals, driving the motor, and controlling the heating element to achieve fast and efficient drying of clothes.

Structural Components of Clothes Dryer PCB

The structural components of the clothes dryer PCB primarily include:

Microprocessor: Responsible for receiving and analyzing sensor signals. It controls the motor and heating element based on preset algorithms and programs. The microprocessor often integrates modules like ADC (Analog-to-Digital Converter) and PWM (Pulse Width Modulation) for precise control and adjustment.

Power Circuit: Converts input AC power to DC power, providing stable power to the entire PCB. The power circuit typically includes rectifiers, filters, stabilizers, and other components.

Motor Drive Circuit: Drives the motor using power devices such as an H-bridge or transistors, enabling motor rotation in both directions and speed control.

Temperature Sensor and Humidity Sensor: Detects clothing temperature and humidity, converting these signals into electrical signals for transmission to the microprocessor. The microprocessor adjusts the motor and heating element based on these signals for intelligent drying control.

Human-Machine Interface Circuit: Connects external devices such as display panels and operation buttons. This circuit allows users to control and set the dryer's functions easily. The interface circuit usually includes keypad input circuits, LED display driver circuits, and more.

Main Functions of Clothes Dryer PCB

Motor Control: The microprocessor, through the motor drive circuit, controls the motor to rotate in both directions and adjust its speed, enhancing drying efficiency.

Temperature Control: The temperature sensor detects clothing temperature, and the microprocessor adjusts the heating element's operation to maintain the appropriate drying temperature, preventing overheating or damage to the clothes.

Humidity Detection: The humidity sensor detects clothing humidity, and the microprocessor adjusts drying time and temperature based on humidity values, achieving optimal drying results.

Human-Machine Interaction: The human-machine interface circuit, connected to external devices like display panels and operation buttons, allows users to set drying programs, select drying modes, and monitor the drying status, providing a user-friendly experience.

Safety Protection: The clothes dryer PCB includes safety features such as overload protection and overheat protection to prevent motor and heating element damage, ensuring user safety. In case of anomalies, the PCB automatically cuts off power or issues an alarm.

Manufacturing Process of Clothes Dryer PCB

The manufacturing process of clothes dryer PCB involves the following key steps:

Circuit Design and Wiring: Based on product requirements, design the circuit and wiring to determine component positions and connections.

PCB Fabrication: Print and process circuit patterns on copper-clad boards according to the designed circuit diagram, forming multi-layered composite PCBs.

Component Soldering: Solder electronic components onto the PCB according to design specifications to ensure proper arrangement and connections.

Testing and Debugging: Test and debug the assembled PCB to ensure all functions work correctly. Testing includes electrical performance testing, visual inspection, and functional testing.

Assembly and Packaging: Assemble and package PCBs that pass the tests, making them usable components for clothes dryers. The assembly process includes securing the PCB in the appropriate position, connecting the motor, heating element, sensors, etc., and conducting necessary adjustments and tests.

Development Trends of Clothes Dryer PCB

With continuous technological development, clothes dryer PCBs are evolving. Some development trends include:

Smart Technology: By integrating advanced artificial intelligence technologies and algorithms, clothes dryer PCBs will achieve more intelligent drying control and management. For example, automatic identification of clothing types and washing programs using machine learning, intelligent adjustment of drying time and temperature, and IoT technology for remote control and data sharing.

Multifunctional Integration: Future clothes dryer PCBs will trend towards multifunctional integration, incorporating features such as sterilization, dust removal, and providing comprehensive clothing care services. Integration of voice recognition and synthesis technology for voice control and interaction, as well as wireless charging technology for a convenient charging experience.

Energy Efficiency and Environmental Protection: With increased global environmental awareness, clothes dryer PCBs will focus more on energy-efficient and environmentally friendly designs. This may involve using efficient motors and heating elements, optimizing energy utilization efficiency, adopting eco-friendly materials and recyclable designs, and implementing measures to reduce energy consumption and emissions.

Industry Category