what is washing machine pcb?

By:PCBBUY 01/31/2024 23:28

The core of the washing machine PCB is a microprocessor. It receives user instructions from the control panel and signals from sensors to control various components of the washing machine. When users choose different washing programs, set washing temperatures, or select washing modes, these commands are converted into electrical signals by electronic components on the PCB. The microprocessor processes these signals based on preset programs and algorithms, outputs corresponding control signals, and drives components such as motors and solenoid valves to perform the desired functions.

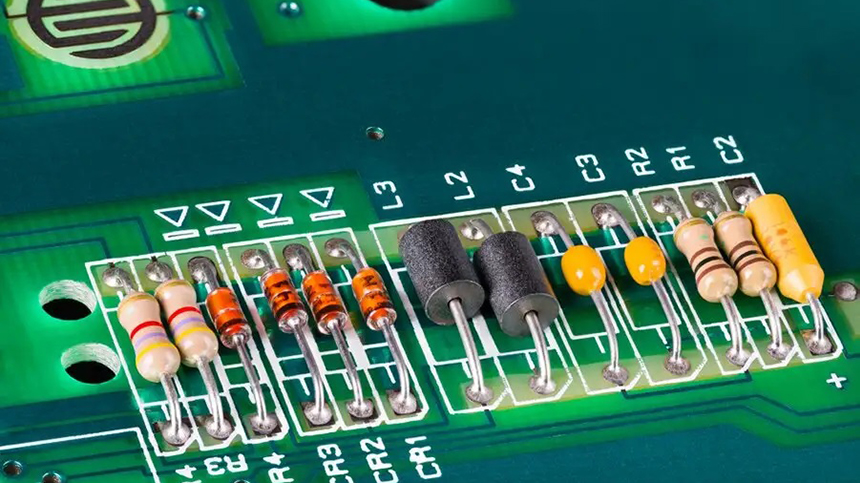

Structural Components of Washing Machine PCB

The washing machine PCB primarily consists of a microprocessor, memory, input-output interfaces, power circuit, clock circuit, etc. The microprocessor serves as the core control unit, managing various commands and signals. Memory stores programs and data, input-output interfaces handle user instructions and sensor signals, the power circuit ensures a stable power supply, and the clock circuit generates clock signals to maintain the proper functioning of the microprocessor.

Main Functions of Washing Machine PCB

Motor Control: The PCB controls the motor by managing its on/off status and speed, facilitating functions such as washing, rinsing, and spinning. The motor drives the agitator or drum to generate washing force.

Solenoid Valve Control: In the water supply system of automatic washing machines, the PCB controls the on/off status of solenoid valves, enabling water inlet and drainage functions.

Detection and Feedback: Sensors on the PCB detect parameters like water level, temperature, and weight, providing feedback to the microprocessor. The microprocessor adjusts and controls operations based on this feedback.

Display and Indication: The PCB is connected to display panels and indicator lights, showing the current operating status, error messages, etc. Users can monitor the washing machine's status and take necessary actions through the display panel.

Safety Protection: The washing machine PCB incorporates protection functions against overcurrent, overvoltage, undervoltage, overheating, etc., preventing equipment damage and ensuring user safety. In case of abnormalities, the PCB can automatically cut off power or issue alarms.

Manufacturing Process of Washing Machine PCB

Manufacturing a washing machine PCB involves the following key processes:

PCB Fabrication: Circuit patterns are printed and processed on copper-clad boards according to the designed circuit diagram, forming multi-layered composite PCBs.

Component Soldering: Electronic components are soldered onto the PCB according to design specifications to ensure proper arrangement and connections.

Testing and Debugging: The assembled PCB undergoes testing and debugging to ensure all functions work correctly. Testing includes electrical performance testing, visual inspection, and functional testing.

Assembly and Packaging: PCBs passing the tests are assembled and packaged to become usable washing machine components. This assembly process includes securing the PCB in the appropriate position, connecting components like motors, solenoid valves, sensors, and conducting necessary adjustments and tests.

Development Trends of Washing Machine PCB

As technology evolves, washing machine PCBs continue to progress. Some development trends include:

Smart Technology: With the advancement of smart technology, washing machine PCBs will become more intelligent, capable of automatic control and optimization. Integration of artificial intelligence allows washing machines to automatically select optimal washing programs and parameters based on factors such as fabric type and stain level.

Energy Efficiency and Environmental Protection: Increased awareness of energy efficiency and environmental concerns will drive washing machine PCBs to focus on eco-friendly designs. This may involve using efficient motors and control algorithms to reduce energy consumption and adopting non-toxic materials and environmentally friendly manufacturing processes.

High Reliability and Longevity: For high-end washing machines, consumers prioritize high reliability and long lifespan. Thus, washing machine PCBs will incorporate higher-quality electronic components and more reliable manufacturing processes to enhance product reliability and lifespan.

Modularity and Expandability: To meet diverse consumer needs and customization requirements, washing machine PCBs will become more modular and expandable. Different modules can be chosen and combined according to specific requirements, facilitating upgrades and maintenance.

Wireless Connectivity: With the development of IoT (Internet of Things) technology, washing machine PCBs will emphasize wireless connectivity. For example, through WiFi, Bluetooth, and other wireless technologies, washing machines can connect to smartphones, smart home systems, enabling convenient and intelligent user experiences.

Industry Category