Control Impedance Guidelines in PCB Manufacturing

By:PCBBUY 11/25/2025 17:36

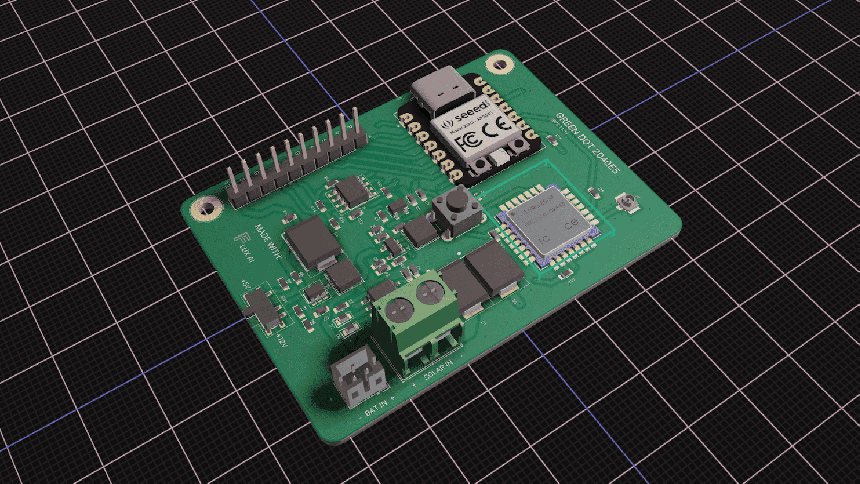

Controlled impedance is a critical requirement in high-speed PCB design where signal integrity must be preserved across transmission lines. This article presents a technical explanation of controlled impedance concepts, influencing parameters, calculation methodology, and PCBBUY’s manufacturing processes for achieving tight impedance control.

In this article, we will explain what control impedance in PCB means, why it is essential, and how PCBBUY achieves consistently accurate results with advanced equipment and strict process control.

What Does Control Impedance in PCB Mean?

Controlled impedance refers to designing and manufacturing PCB traces so their characteristic impedance remains within a defined range (commonly 50Ω, 90Ω, or 100Ω). This is critical for:

-

High-speed signal transmission

-

Differential pair consistency

-

Reducing signal reflection

-

Maintaining data integrity

Common impedance types include:

-

Single-ended impedance for RF or high-speed microstrip lines

-

Differential impedance for pairs such as USB, HDMI, LVDS, CAN, and Ethernet

When impedance is inaccurate, the result may include distorted signals, EMI issues, or outright communication failure.

Key Factors Affecting Controlled Impedance

Achieving proper impedance requires controlling several PCB parameters simultaneously:

1. Dielectric Thickness

For accurate impedance, the spacing between copper trace and reference ground layer is critical.

PCBBUY uses high-precision lamination equipment to maintain dielectric thickness consistency within tight tolerances.

2. Dielectric Constant (Dk)

Different PCB materials—FR4, Rogers, Isola, Panasonic—have varying dielectric constants that influence impedance values.

PCBBUY works with globally trusted material suppliers to guarantee stable Dk performance.

3. Copper Thickness

The copper weight (½ oz, 1 oz, 2 oz, etc.) changes trace height and directly affects impedance.

4. Trace Width & Spacing

LDI (Laser Direct Imaging) used at PCBBUY ensures excellent line width accuracy, enabling stable single-ended and differential impedance structures.

5. Solder Mask

Even the thickness of solder mask over a microstrip trace can slightly change impedance.

PCBBUY accounts for these variations during stackup design.

How PCBBUY Calculates & Controls Impedance?

Engineering Evaluation

Our engineering team performs detailed impedance calculations using:

-

Polar SI9000

-

Saturn PCB Toolkit

-

Internal material database

We evaluate trace geometry, layer stackup, and manufacturing tolerances before production.

Customized Stackup Design

PCBBUY provides free impedance stackup recommendations based on project requirements, including:

-

Material selection

-

Prepreg/core thickness

-

Copper weight options

-

Target impedance values

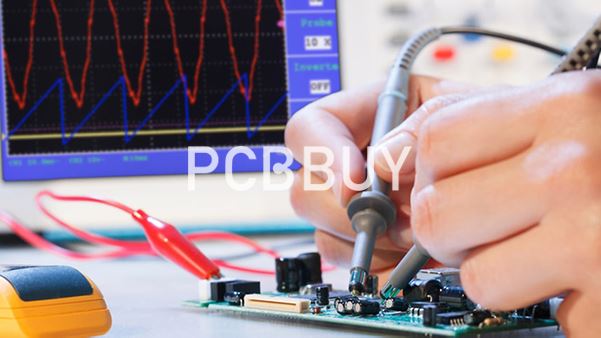

Impedance Coupon Production

A test coupon is added to every controlled-impedance order.

PCBBUY performs TDR (Time-Domain Reflectometry) testing to verify values before shipment.

Where Controlled Impedance PCBs Are Used?

You will find controlled impedance requirements in:

-

5G communication hardware

-

High-speed data interfaces

-

Networking routers and switches

-

Automotive ADAS systems

-

RF circuits

-

Industrial automation equipment

-

Servers and cloud computing systems

PCBBUY manufactures impedance-critical boards for global customers in these industries.

Why PCBBUY Excels in Controlled Impedance PCB Manufacturing?

-

Advanced LDI imaging & high-precision etching

-

Accurate lamination control

-

Professional impedance engineering support

-

Full TDR test reports for every lot

-

Capability with FR4 and complex high-frequency materials

-

Fast lead-time with stable quality

For customers who need reliable high-speed signal performance, PCBBUY delivers consistent and accurate results.

Conclusion

Understanding control impedance in PCB is essential for stable high-speed electronics. With precise materials, advanced equipment, and experienced engineers, PCBBUY provides consistent impedance control that supports even the most demanding applications.

Need assistance with impedance design or stackup suggestions?

PCBBUY’s engineering team is ready to help.

FAQ

1. What is controlled impedance in PCB manufacturing?

It refers to designing PCB traces to match a target impedance value for stable high-speed signal transmission.

2. Why does impedance matter?

Incorrect impedance can cause data errors, signal reflections, and EMI problems.

3. Can PCBBUY perform TDR impedance testing?

Yes. Every impedance order includes a TDR-tested coupon.

4. What tolerance can PCBBUY achieve?

Typically ±10%, depending on the stackup and materials.

5. Which materials are best for stable controlled impedance?

High-frequency materials like Rogers, Isola, Panasonic, and high-TG FR4.

6. Does solder mask affect impedance?

Yes, especially for microstrip designs; PCBBUY accounts for this in calculations.

7. Can PCBBUY help design the impedance stackup?

Yes, PCBBUY provides free engineering support and stackup recommendations.

Industry Category