Counterbored Holes Drilling Capabilities in PCB Manufacturing

By:PCBBUY 07/14/2025 16:12

What Are Counterbored Holes in PCB Manufacturing?

In printed circuit board (PCB) manufacturing, counterbored holes play a vital role in combining electronic and mechanical functionality. These specialized holes, machined to accommodate screw heads or mechanical components, ensure flush mounting and structural integrity in final assemblies. As devices get smaller and more complex, the demand for precision drilling—especially for counterbored features—has grown significantly.

At PCBBUY, we deliver advanced counterbored hole processing as part of our custom PCB solutions, ensuring high mechanical accuracy with tight tolerances and full customization capabilities.

The Function and Application of Counterbored Holes

Counterbored holes allow for components such as screws or connectors to sit flush with or below the PCB surface. These holes are often used in:

-

Rigid PCB and metal core board mounting

-

High-speed connector seating

-

Heat sink and thermal pad alignment

-

Mechanical modules requiring secure fasteners

Compared to standard through-holes, counterbored holes offer superior mechanical performance and aesthetics in precision assemblies.

Types of Counterbored Holes Supported at PCBBUY

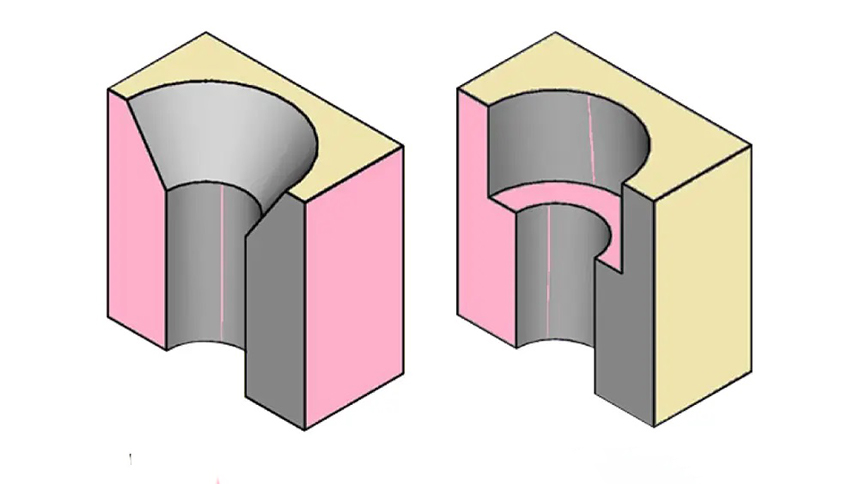

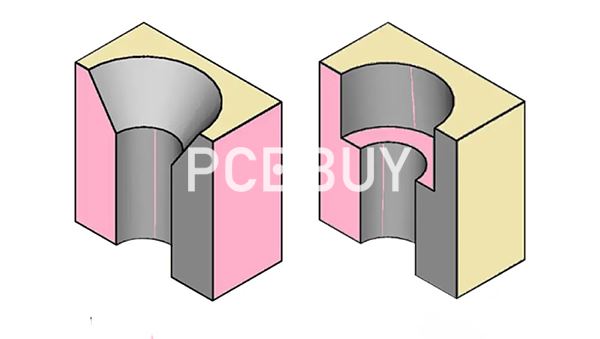

At PCBBUY, we support both T-shaped and V-shaped counterbore structures, tailored to fit different mechanical configurations:

✅ T-shaped Counterbored Holes

-

Depth: ≥ 0.2mm

-

Hole Size: ≥ 2mm

-

PTH Tolerance: ±0.2mm

-

NPTH Tolerance: ±0.15mm

-

Customization: Deep borehole structures can be customized on request.

This type is ideal for components requiring secure vertical seating or recessed screws with straight sidewalls.

✅ V-shaped Counterbored Holes

-

Angle: Normal 90°

-

Hole Size: 4–20mm

-

PTH Tolerance: ±0.2mm

-

NPTH Tolerance: ±0.15mm

-

Customization: Horn hole shapes and non-standard depths can be tailored to your design.

V-shaped holes provide optimal seating for conical screw heads and are commonly used in high-torque mechanical applications.

Precision Drilling Equipment at PCBBUY

To achieve consistent and reliable counterbored hole fabrication, PCBBUY utilizes:

-

CNC Drilling Machines with multi-axis depth control

-

Automatic Optical Inspection (AOI) for alignment accuracy

-

X-ray Drilling Positioning for multilayer boards

-

CAM Review Services to validate counterbore specifications before production

These advanced systems ensure tight control over hole diameters, wall quality, and depth consistency.

Why PCBBUY Is Your Trusted Counterbored Holes PCB Factory

PCBBUY offers industry-leading customization, scalability, and turnaround speed for boards requiring counterbores:

|

Feature |

PCBBUY Capabilities |

|

Hole Size Range |

2mm to 20mm |

|

Depth Control |

Starting from 0.2mm |

|

Tolerance |

±0.2mm (PTH), ±0.15mm (NPTH) |

|

Types Supported |

T-shaped & V-shaped counterbores |

|

Special Services |

Horn holes, deep boreholes, hybrid layouts |

Whether you need counterbores on HDI boards, aluminum substrates, or flex-rigid hybrids, our engineering team is ready to offer expert guidance and rapid prototyping.

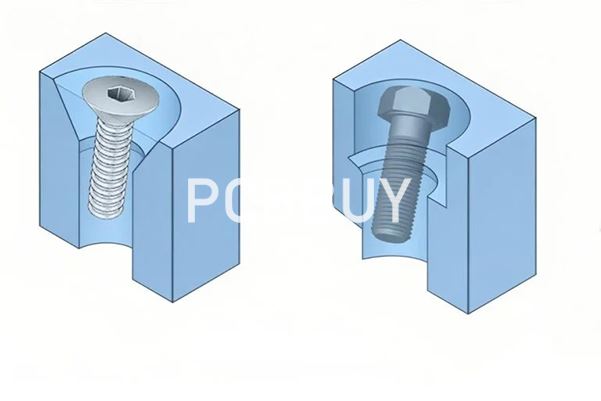

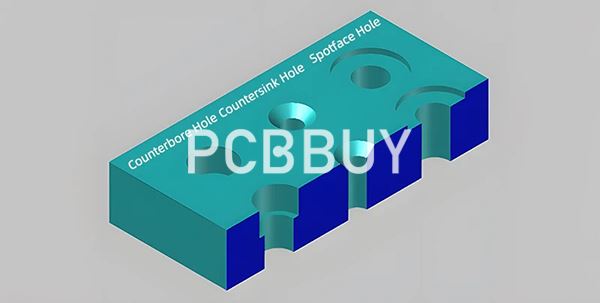

Counterbored Holes vs Countersunk Holes: What’s the Difference?

|

Feature |

Counterbored Holes |

Countersunk Holes |

|

Shape |

Cylindrical Recess |

Conical Recess |

|

Usage |

Flat screw heads |

Tapered screw heads |

|

Depth |

Uniform |

Tapered |

|

Typical Angle |

90° or flat-bottom |

~82° (standard) |

Real-World Applications: How PCBBUY Supports High-End Clients

Our counterbored hole services are frequently used in:

-

Telecom base stations requiring heavy-duty screw mounting

-

Automotive dashboards for vibration-resistant assembly

-

Industrial robots where mechanical and electrical integration is critical

By optimizing depth, tolerance, and alignment, we help ensure mechanical strength without compromising electrical performance.

FAQs Counterbored Holes in PCB Production

Q1: Can counterbored holes be plated?

A: Yes. Both PTH (Plated Through-Hole) and NPTH (Non-Plated Through-Hole) options are available, depending on your design needs.

Q2: What is the minimum depth for a counterbored hole?

A: At PCBBUY, the minimum standard depth starts from 0.2mm. For custom projects, we support even deeper boreholes upon request.

Q3: Can I combine counterbores with vias or pads?

A: Yes, with proper design review. Our engineers will assess risks of interference and alignment mismatches to ensure structural integrity.

Q4: What is the maximum angle supported for V-shaped counterbores?

A: We support standard 90°, but other angles may be evaluated upon drawing submission.

Conclusion

Counterbored holes are more than a mechanical feature—they’re a key part of PCB functionality and reliability. At PCBBUY, our manufacturing precision, customized engineering, and world-class support make us a trusted counterbored holes PCB factory partner for global clients across industries.

Ready to quote your design? Contact our engineering team or upload your Gerber files now.

Industry Category