ENIG PCB Surface Finish A Precision Gold Plating Technology

By:PCBBUY 07/31/2025 17:33

In high-reliability electronic assemblies, surface finish plays a vital role in ensuring solderability, corrosion resistance, and signal integrity. One of the most trusted finishes in the PCB manufacturing industry is the ENIG PCB surface finish. At PCBBUY, we offer advanced ENIG capabilities that meet stringent international standards while delivering exceptional durability and performance.

What is ENIG PCB Surface Finish?

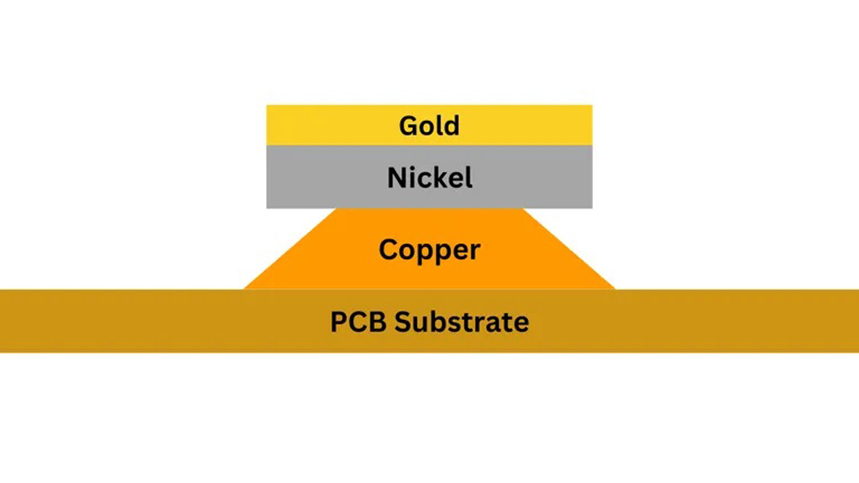

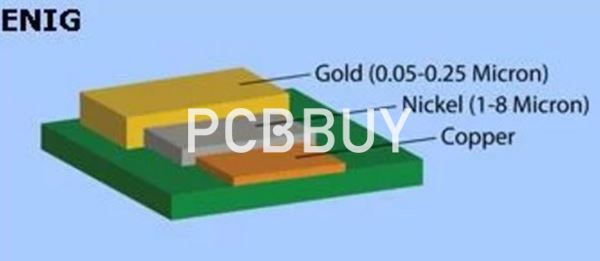

ENIG stands for Electroless Nickel Immersion Gold. This surface finish involves a two-layer metal deposition:

-

A layer of electroless nickel protects the underlying copper and provides a reliable soldering base.

-

A thin immersion gold layer protects the nickel from oxidation and ensures excellent wire bonding.

This combination makes ENIG an ideal choice for applications requiring flatness, long shelf life, and high signal performance—especially in BGA, CSP, QFN, and HDI boards.

PCBBUY’s ENIG PCB Surface Finish Capabilities

At PCBBUY, we adhere to industry best practices to ensure your ENIG surface finish is uniform, consistent, and reliable.

✅ Standard ENIG Thickness at PCBBUY

|

Material |

Thickness (μin) |

Remarks |

|

Nickel |

100–200 μin |

Special thicknesses available upon request |

|

Gold |

Typically 1–5 μin |

Compliant with IPC-4552 standards |

-

All measurements are verified using XRF thickness testing systems.

-

Special requirements for custom nickel or gold thickness can be specified per project.

-

ENIG coating is performed in dedicated plating lines, with strict process monitoring.

ENIG PCB Surface Finish Process Flow at PCBBUY

Our in-house ENIG process involves a tightly controlled, multi-step sequence:

-

Copper Surface Cleaning

Removes oxides and prepares the surface for plating.

-

Micro-Etching and Activation

Roughens the copper for better adhesion and activates the surface.

-

Electroless Nickel Deposition

A uniform nickel layer is deposited without electric current. This layer forms the primary barrier for corrosion and ensures mechanical strength.

-

Immersion Gold Plating

A thin gold layer is deposited via displacement reaction with nickel, forming a corrosion-resistant surface ideal for soldering and bonding.

-

Rinsing and Drying

Final cleaning and drying under controlled conditions to prevent surface contamination.

Benefits of ENIG PCB Surface Finish

-

✅ Flat Surface Finish – Suitable for BGA/QFN packages with tight pitch

-

✅ Superior Solderability – Excellent wetting with all lead-free solder alloys

-

✅ Long Shelf Life – Gold protects nickel from oxidation over extended storage

-

✅ Wire Bonding Compatibility – Ideal for gold wire bonding

-

✅ RoHS Compliant – No lead used in plating process

-

✅ Low Contact Resistance – Supports high-speed and RF applications

Application Areas of ENIG PCBs

ENIG is widely used in sectors where quality and reliability are non-negotiable:

-

Consumer Electronics – Smartphones, tablets, wearables

-

Medical Devices – Implantables, imaging systems

-

Aerospace and Defense – Radar systems, avionics, satellites

-

Automotive Electronics – ADAS, ECU, infotainment modules

-

Telecommunication – Routers, base stations, 5G systems

How PCBBUY Ensures ENIG Quality and Consistency

At PCBBUY, we take pride in offering world-class plating performance:

-

💡 Automated Plating Line Control – Ensures consistent chemical ratios and bath quality

-

📏 XRF Thickness Testing – Real-time monitoring of both nickel and gold layers

-

🔧 Custom Engineering Support – Tailored finishes for your product’s unique requirements

-

🌍 Global Delivery – Fast turnaround and international shipping support

-

📄 DFM Reviews – Surface finish suitability assessment before production

ENIG vs Other Surface Finishes: Why Choose ENIG?

|

Finish Type |

Flatness |

Solderability |

Shelf Life |

Wire Bonding |

Cost |

|

ENIG |

Excellent |

Excellent |

Long |

Yes |

Moderate |

|

HASL |

Poor |

Good |

Moderate |

No |

Low |

|

OSP |

Good |

Good |

Short |

No |

Low |

|

ENEPIG |

Excellent |

Excellent |

Long |

Yes (better) |

High |

Conclusion

If you're looking for a stable, durable, and high-precision ENIG PCB surface finish, PCBBUY is your trusted manufacturing partner. Our state-of-the-art plating systems, global delivery capabilities, and engineering excellence ensure that every ENIG board meets your expectations—and then some.

Contact our engineering team to get a free ENIG specification review or a fast quote for your project today.

Industry Category