Mastering the HDI PCB Manufacturing Process

By:PCBBUY 06/26/2025 17:10

Why Understanding the HDI PCB Manufacturing Process Matters?

As electronics become increasingly compact and powerful, High-Density Interconnect (HDI) PCBs have emerged as the backbone of advanced technology. Whether you are building next-gen smartphones, IoT devices, or aerospace applications, understanding the HDI PCB manufacturing process is critical to achieving both performance and reliability.

PCBBUY, a leading global PCB manufacturer, is proud to offer cutting-edge HDI PCB solutions tailored to meet the most demanding requirements. In this guide, we outline the full spectrum of PCBBUY's HDI capabilities, step-by-step processes, and the engineering standards we maintain to ensure superior quality.

1. HDI PCB Material Selection

|

Item |

Standard |

Remarks |

|

Material |

FR-4 |

TG135–TG170, halogen-free and CTI materials available upon request |

At PCBBUY, we use industry-proven materials like FR-4 for standard HDI builds, while also offering high-Tg, halogen-free options for high-performance applications. Customized dielectric materials are also available based on impedance or CTI needs.

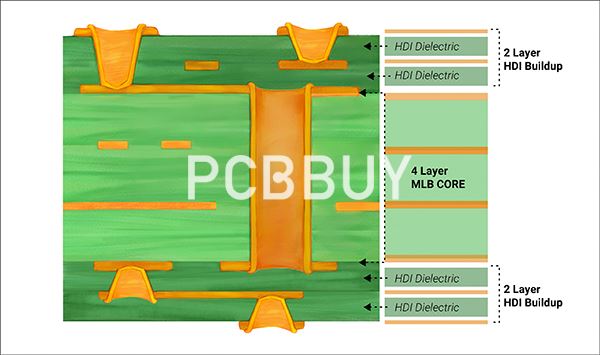

2. HDI Layer Count and Stack-Up Options

|

Item |

Standard |

Remarks |

|

Number of Layers |

1st Order: 4-10 layers2nd Stage: 6-10 layers |

Custom stack-ups available |

From basic 1+N+1 to more advanced 2+N+2 constructions, PCBBUY supports multi-layer HDI PCB builds. Our engineers help you optimize layer configurations for signal integrity, cost, and thermal reliability.

3. Advanced Construction Types

|

Item |

Standard |

Remarks |

|

Construction Type |

1st order: 1+N+1, 1+1+N+1 +12nd order: 2+N+2, 1+2+N+2+1 |

Electroplated via filling available |

Our HDI stack-ups are engineered for high-density interconnects using buried and blind vias. For finer vias (≤0.3mm), we use electroplating filling processes to ensure signal continuity and mechanical reliability.

4. Trace Width Capabilities

|

Item |

Standard |

Remarks |

|

Trace Width |

2/2mil (min) |

Ideal for HDI/BGA and fine-pitch ICs |

PCBBUY leverages advanced imaging and etching technology to achieve minimum 2mil line/space designs. This enables complex routing for high-speed and RF circuits in HDI designs.

5. Blind Via Technology

|

Item |

Standard |

Remarks |

|

Blind Via |

Mechanical ≥0.15mmLaser ≥0.075mm |

Specification review required |

Our blind via drilling capabilities include high-precision laser and mechanical processes. All via geometries are reviewed and validated before fabrication to ensure manufacturability and reliability.

6. Hole Size and Registration

|

Item |

Standard |

Remarks |

|

Hole Size |

Min unilateral ≥3mil |

Custom drills possible on request |

With advanced CNC and laser drills, PCBBUY achieves micro-drilling tolerances ideal for stacked via and via-in-pad structures.

7. Hole Copper Thickness

|

Item |

Standard |

Remarks |

|

Hole Copper |

>18μm (mechanical)>13μm (laser) |

Review required |

Ensuring sufficient copper thickness in vias is crucial for conductivity and reliability. PCBBUY uses tightly controlled plating parameters to ensure IPC standards are met.

8. Via Electroplating Process

|

Item |

Standard |

Remarks |

|

Via Electroplating |

Depth: 0.05mm~0.1mmTolerance: ±15% |

Full via copper fill ensures metallization |

Using advanced electroplating systems, we fill microvias with copper to guarantee structural strength and thermal reliability. This is especially important for stacked or staggered vias in multi-order HDI designs.

Why Choose PCBBUY for HDI PCB Manufacturing?

-

Customized HDI Stack-Ups: We support all mainstream and specialized configurations.

-

Precision Laser Drilling: For clean microvias down to 0.075mm.

-

LDI & Fine-Line Imaging: Accurate 2/2mil trace widths.

-

Advanced Plating Lines: Ensure copper fill, reliability, and consistent via quality.

-

Global Delivery & Support: From prototyping to mass production.

Conclusion

Understanding the HDI PCB manufacturing process allows engineers and product managers to make smarter design and sourcing decisions. With PCBBUY's proven manufacturing expertise and a commitment to advanced technology, we’re here to bring your HDI designs to life with speed, precision, and reliability.

Industry Category