PCB Solder Mask Colors Guide for Global Buyers

By:PCBBUY 11/20/2025 10:46

Solder mask color selection is an important part of PCB fabrication parameters. While its primary function is protection, the color formulation directly affects exposure resolution, AOI detectability, thermal behavior, and long-term material stability.

This document provides a technical overview of pcb solder mask colors, referencing PCBBUY’s production capabilities and process controls.

At PCBBUY, we handle thousands of boards in different solder mask colors every month, so we’ve seen how choosing the right color can make production simpler—or more complicated. This guide walks you through the key things you should know before choosing a solder mask color for your PCB project.

What PCB Solder Mask Colors Actually Do?

Solder mask is a protective coating that sits on top of the PCB surface. It prevents oxidation, controls solder flow during assembly, and gives the board a clean, uniform look.

While all colors share the same basic function, different pigments can influence:

-

heat absorption

-

resolution during exposure

-

how AOI (Automated Optical Inspection) detects pads

-

long-term color stability

-

visibility of tracks and pads

This is why understanding pcb solder mask colors matters for both engineering and manufacturing.

The Most Popular PCB Solder Mask Colors

Green: The Industry Standard

Green is the most balanced solder mask color for nearly all applications.

It offers:

-

excellent exposure resolution

-

high contrast with copper pads

-

stable performance under high temperatures

Most high-density boards still prefer green. At PCBBUY, more than 70% of production uses premium Taiyo green solder mask for maximum consistency.

Black: Premium Look, Higher Requirements

Black looks sleek, especially for consumer electronics or premium gadgets.

But it has some challenges:

-

absorbs more heat

-

lower visibility during inspection

-

prone to showing scratches

PCBBUY uses an enhanced black mask formula to reduce white marks and improve surface hardness, making it suitable even for mass production.

White: Best for LED Applications

White solder mask is commonly used in:

-

LED light bars

-

display panels

-

lighting modules

It provides strong light reflection. However, white can reduce the visibility of fine traces. Our production team uses high-clarity imaging processes to ensure stable resolution for white-mask PCBs.

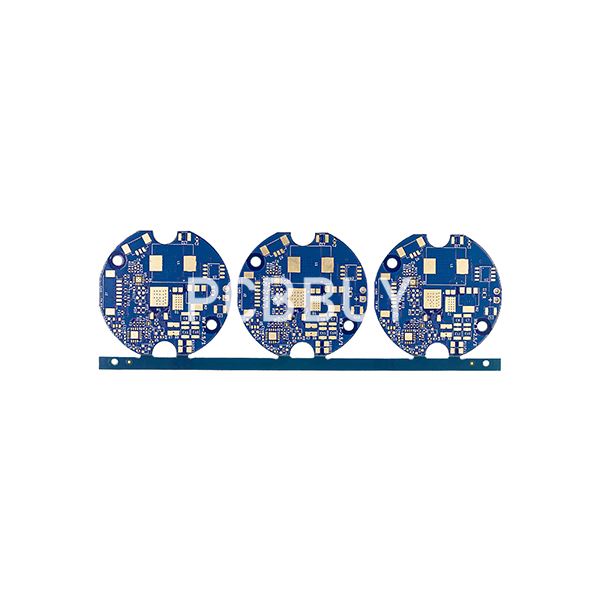

Blue: Clean, High-Tech Appearance

Blue is popular for high-end prototypes or brands that want a unique visual identity.

Its advantages:

-

good AOI contrast

-

aesthetic appearance

-

stable performance during reflow

PCBBUY keeps strict controls on blue mask color uniformity to avoid uneven tones.

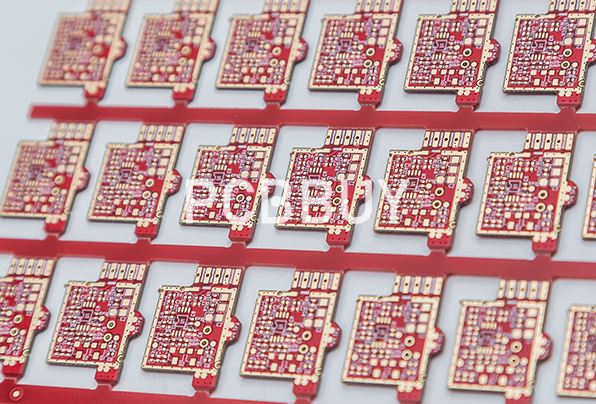

Red, Yellow, and Custom Colors

For educational boards, promotional products, or custom branding, colored masks like red or yellow are common choices.

PCBBUY also supports:

-

purple

-

matte black

-

matte green

-

customized Pantone color matching

If a brand wants its PCB to stand out, custom colors are one of the easiest ways.

How Different Solder Mask Colors Influence Manufacturing?

1. Resolution & Fine-Pitch Traces

Not every color performs the same during imaging. Green offers the best resolution; black and white are slightly weaker.

To ensure precise line definition, PCBBUY uses:

-

LDI (Laser Direct Imaging)

-

25µm resolution control

-

fine-pitch optimization settings

This guarantees consistent quality across all colors.

2. Heat Resistance

Dark colors absorb more heat during reflow soldering. PCBBUY compensates for this by adjusting pre-bake and reflow profiles when needed.

3. AOI (Automated Optical Inspection)

Some colors lower contrast between pads and solder mask. To solve this, PCBBUY uses AOI contrast enhancement algorithms customized for each color type.

PCBBUY’s Capabilities in Multicolor Solder Mask Production

-

Advanced automatic coating lines

-

Laser direct imaging for high precision

-

Taiyo & KuangCheng high-performance solder mask inks

-

Strict color uniformity inspection

-

Support for both prototype & mass production

-

Custom color development for branding projects

With 10+ years of experience in PCB manufacturing, PCBBUY can meet diverse color and performance requirements.

Engineering Recommendations for Choosing Solder Mask Colors

|

Application Type |

Recommended Color |

Notes |

|

HDI / Fine Pitch |

Green |

Best resolution & AOI compatibility |

|

Consumer Electronics |

Black / Blue |

Consider AOI adjustments |

|

LED / Lighting |

White |

High reflectivity needed |

|

Branding / Education |

Red / Yellow / Custom |

Custom Pantone supported |

How to Choose the Right Solder Mask Color?

For technical performance → Choose green

Best for fine-pitch, high-density, and industrial-grade electronics.

For aesthetics or branding → Black / Blue / Red

Choose based on visibility and product identity.

For lighting applications → White

Best reflectivity for LED modules.

For prototypes or custom builds → Any color

PCBBUY supports custom Pantone color matching.

Conclusion

Choosing the right solder mask color is more than a visual decision—it affects manufacturing, inspection, and long-term reliability. With PCBBUY’s advanced solder mask technology and wide color options, global buyers can get boards that look good and perform even better.

FAQ

Q1: Does solder mask color affect PCB cost?

Green is the most economical. Special colors may add 5–15% cost depending on ink type.

Q2: Can PCBBUY produce custom Pantone-matched colors?

Yes, our factory supports custom color development for branding or special projects.

Q3: Which solder mask color is best for fine-pitch PCB designs?

Green has the best imaging resolution and inspection contrast.

Industry Category