PCB Testing Techniques Ensuring Reliability with PCBBUY

By:PCBBUY 08/27/2025 16:04

Introduction to PCB Testing Techniques

Printed Circuit Boards (PCBs) are the backbone of modern electronics, powering everything from smartphones and automotive systems to medical devices and 5G networks. To guarantee product reliability and performance, pcb testing techniques play a critical role in manufacturing.

At PCBBUY, we combine state-of-the-art testing equipment with strict quality management systems to ensure that every PCB meets international standards. This article explores the most common pcb testing techniques, while showcasing how PCBBUY’s advanced capabilities set us apart in the global PCB manufacturing industry.

Importance of PCB Testing in Electronics Manufacturing

High-quality PCBs are essential for the stable operation of electronic devices. Defects in a circuit board can lead to product malfunction, costly recalls, and even safety issues. By applying robust pcb testing techniques, manufacturers can:

-

Verify electrical continuity and insulation resistance.

-

Detect surface and internal defects before shipment.

-

Reduce failure rates and repair costs.

-

Meet international certifications such as ISO, UL, and IPC standards.

At PCBBUY, testing is not just a final step—it is integrated into every stage of our production process, from raw material inspection to final delivery.

Common PCB Testing Techniques

Visual Inspection in PCB Testing Techniques

Visual inspection is the most fundamental form of PCB testing. Using magnification tools or microscopes, operators can quickly identify issues such as scratches, solder splashes, or misalignments. While this method is effective for small-batch or prototype boards, it cannot cover high-volume production.

👉 PCBBUY integrates visual inspection into the early manufacturing stage to catch visible defects before advanced testing begins.

Automated Optical Inspection (AOI) in PCB Testing Techniques

AOI uses high-resolution cameras to scan the PCB surface, comparing it to design files to detect open circuits, shorts, or misaligned components. This technique is fast, accurate, and suitable for large-scale production.

👉 PCBBUY employs high-speed AOI systems that can identify micron-level defects, ensuring the precision of fine-pitch designs in HDI and multilayer PCBs.

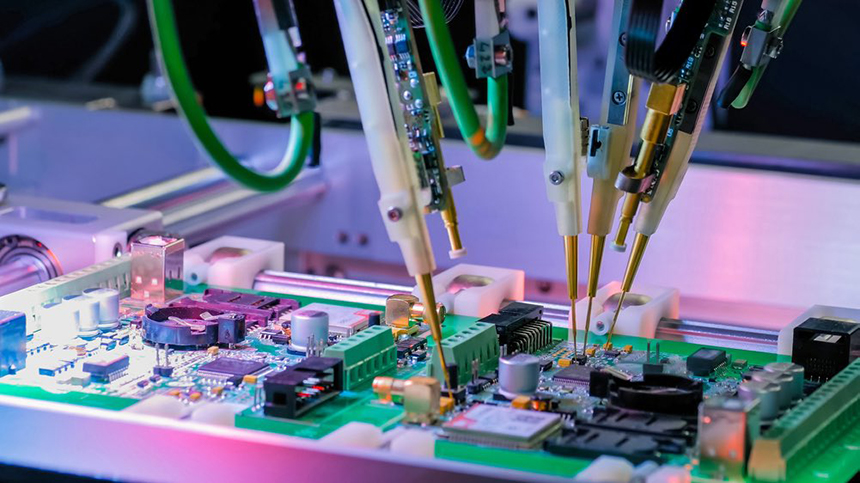

Flying Probe Testing in PCB Testing Techniques

Flying probe testing uses movable probes to contact PCB pads and vias without requiring expensive fixtures. It is ideal for prototypes and small production runs. The method checks for opens, shorts, and component values with high precision.

👉 PCBBUY leverages flying probe testing for rapid prototyping and small-batch orders, offering customers flexible testing solutions with short turnaround times.

In-Circuit Testing (ICT) in PCB Testing Techniques

ICT relies on a “bed-of-nails” fixture to quickly test large volumes of PCBs. It can measure resistance, capacitance, and verify solder joint integrity. While setup costs are higher, ICT is efficient for mass production.

👉 PCBBUY provides customized ICT fixture solutions, ensuring fast and accurate testing for clients with high-volume needs.

Functional Testing in PCB Testing Techniques

Functional testing simulates the actual operating conditions of a PCB, verifying that it performs as expected in real-world environments. This step is crucial for mission-critical industries such as automotive, aerospace, and medical devices.

👉 PCBBUY offers tailor-made functional testing, ensuring that our customers’products meet both design specifications and regulatory requirements.

Advanced PCB Testing Techniques at PCBBUY

Beyond the standard methods, PCBBUY invests in advanced testing technologies to meet the demands of high-density and high-frequency PCBs:

-

X-ray Inspection: Detects hidden solder defects in BGA, CSP, and buried via structures.

-

Micro-section Analysis: Provides cross-sectional views to evaluate copper plating, layer adhesion, and via quality.

-

Thermal Stress Testing: Assesses PCB durability under extreme temperature cycles.

-

High-Voltage (Hi-Pot) Testing: Measures insulation resistance and dielectric breakdown.

-

Impedance Testing: Ensures precise impedance control for high-speed communication boards.

By combining these advanced pcb testing techniques, PCBBUY guarantees that our PCBs are not only defect-free but also optimized for performance.

PCBBUY’s Advantages in PCB Testing Techniques

What sets PCBBUY apart from other manufacturers is our integrated testing workflow:

-

Full-process control: From incoming material inspection to 100% final testing.

-

Cutting-edge equipment: AOI, X-ray, flying probe, ICT, impedance analyzers.

-

Certifications: Compliance with ISO9001, UL, RoHS, IPC Class 2 and Class 3 standards.

-

Flexibility: Testing support for both prototypes and mass production.

-

Industry applications: Telecom, automotive, consumer electronics, industrial control, and healthcare.

This comprehensive approach allows PCBBUY to deliver reliable PCBs trusted by global clients.

Challenges in PCB Testing and PCBBUY’s Solutions

As PCB designs become more complex, testing also faces challenges such as:

-

Detecting hidden defects in microvias and BGAs.

-

Balancing testing cost with efficiency.

-

Reducing lead times for high-volume ICT fixtures.

👉 PCBBUY addresses these challenges by investing in 3D X-ray technology, automating AOI processes, and optimizing fixture design for cost efficiency.

Future Trends in PCB Testing Techniques

The future of PCB testing will be shaped by:

-

AI-driven defect detection for faster and more accurate analysis.

-

5G and high-frequency testing for next-generation communication boards.

-

Non-destructive inspection techniques to preserve valuable prototypes.

-

Digital twin integration for simulation-based validation.

PCBBUY continuously upgrades our equipment and R&D efforts to stay ahead of these industry trends, ensuring our clients always benefit from the most advanced pcb testing techniques available.

Conclusion

Reliable PCBs are the foundation of modern electronics, and robust pcb testing techniques are the key to achieving that reliability. By combining traditional methods with advanced testing technologies, PCBBUY ensures that every PCB we manufacture meets the highest standards of quality and performance. Whether you need prototypes, small batches, or mass production, PCBBUY offers comprehensive testing solutions tailored to your requirements.

👉 Contact PCBBUY today to learn how our advanced PCB testing and manufacturing capabilities can support your next project.

FAQ on PCB Testing Techniques

Q1: What is the difference between AOI and X-ray testing?

AOI inspects surface defects using cameras, while X-ray testing detects hidden internal defects such as BGA solder voids.

Q2: Why is functional testing important for PCBs?

It verifies that the PCB performs correctly in real operating conditions, ensuring product reliability.

Q3: How does PCBBUY ensure PCB testing accuracy?

We use advanced AOI, X-ray, ICT, and flying probe systems, combined with strict quality standards.

Q4: Can PCBBUY provide testing reports for certification?

Yes, we provide detailed test reports aligned with ISO, IPC, and UL requirements.

Q5: Which industries benefit most from advanced PCB testing?

Industries such as telecommunications, automotive, aerospace, medical devices, and industrial automation rely heavily on advanced PCB testing.

Industry Category