Understand Design Calculations of PCB Copper Trace Resistance Calculator

By:PCBBUY 12/30/2025 14:17

Introduction

Copper trace resistance plays a critical role in PCB electrical performance, especially in power distribution and high-current applications. As designs become more compact and current densities increase, many engineers rely on a pcb copper trace resistance calculator during the design phase.

However, calculated resistance values are only accurate when manufacturing variables are properly controlled. Understanding the relationship between design calculations and actual PCB fabrication is essential for reliable results.

What Is a PCB Copper Trace Resistance Calculator?

A PCB copper trace resistance calculator is a design tool used to estimate the electrical resistance of a copper trace based on physical parameters such as length, width, and thickness.

These calculators provide quick reference values during routing and power integrity analysis.

While useful, calculators assume ideal conditions and do not account for all manufacturing variations.

Key Parameters Used in Copper Trace Resistance Calculation

Trace Length

Electrical resistance increases linearly with trace length.

Longer routing paths result in higher resistance and greater voltage drop, particularly in power circuits.

Trace Width

Wider traces reduce resistance by increasing cross-sectional area.

However, achievable trace width is limited by PCB fabrication capability and etching tolerance.

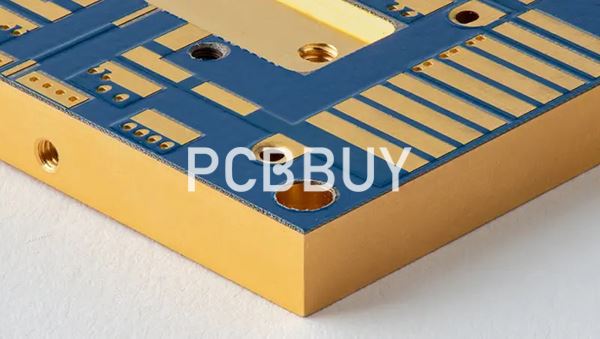

Copper Thickness

Copper thickness is a major factor in resistance calculation.

Standard copper weights such as 1 oz or 2 oz represent nominal values, but finished copper thickness may vary due to plating and process control.

Copper Material and Temperature

Copper resistivity changes with temperature.

Most pcb copper trace resistance calculator tools assume room temperature, which may not reflect real operating conditions.

Why Calculated Resistance Often Differs from Actual PCB Performance?

Etching Tolerance and Line Width Variation

During etching, trace width may deviate slightly from the design value.

These small variations can significantly impact resistance in fine-line designs.

Copper Plating Uniformity

Electroplating increases copper thickness, especially in vias and holes.

Uneven plating can affect trace cross-section and resistance consistency.

Surface Finish and Process Effects

Surface finishes and multiple processing steps may slightly alter the effective copper thickness.

These effects are usually small but should be considered in precision designs.

Manufacturing Challenges Related to Copper Trace Resistance

Managing copper trace resistance is a common pcb manufacturing challenge, particularly for:

-

High-current PCBs

-

Fine-line and high-density designs

-

Multilayer boards with power planes

-

Applications requiring low voltage drop

Manufacturing capability directly determines how closely the final PCB matches calculated resistance values.

How Manufacturing Capability Improves Resistance Accuracy?

Controlled Etching Processes

Precise etching control helps maintain consistent trace width across the panel.

Line width compensation is often applied to match design intent.

Copper Thickness Control and Measurement

Stable plating processes and thickness monitoring ensure uniform copper distribution.

This is essential for resistance-sensitive applications.

Process Monitoring and Quality Inspection

In-process inspection and statistical process control help reduce variation between production batches.

PCBBUY’s Approach to Copper Trace Resistance Control

PCBBUY focuses on engineering-driven PCB manufacturing to ensure predictable electrical performance.

By controlling etching accuracy, copper plating uniformity, and overall process stability, PCBBUY helps bridge the gap between theoretical calculation and real-world PCB performance.

Key strengths include:

-

Experience with fine-line and high-current PCB manufacturing

-

Control of finished copper thickness for export-quality PCBs

-

Engineering support for resistance- and current-sensitive designs

-

Stable production from prototype to mass manufacturing

Design Tips When Using a PCB Copper Trace Resistance Calculator

To improve design reliability, engineers should:

-

Add safety margins for manufacturing tolerance

-

Clearly specify copper thickness requirements

-

Consider operating temperature and current load

-

Engage the PCB manufacturer early for DFM review

A pcb copper trace resistance calculator should be used as a reference, not as the only decision-making tool.

Calculator vs Manufacturing Reality

Resistance calculators are valuable design tools, but they cannot replace manufacturing validation. Actual PCB performance depends on material selection, process control, and inspection standards. Collaboration between design and manufacturing teams ensures calculated resistance values align with finished PCB results.

Conclusion

Copper trace resistance is influenced by both design parameters and manufacturing quality.

While a pcb copper trace resistance calculator provides a useful starting point, manufacturing capability ultimately determines real-world performance.

By combining engineering expertise and process control, PCBBUY supports reliable PCB production for resistance-sensitive applications.

FAQ

What is a PCB copper trace resistance calculator?

It is a design tool used to estimate the electrical resistance of PCB copper traces based on length, width, and thickness.

How accurate are PCB copper trace resistance calculators?

Calculators provide theoretical estimates. Actual resistance depends on manufacturing tolerance, copper thickness variation, and temperature.

Does copper thickness change after PCB fabrication?

Yes. Copper plating and process variations can affect the final copper thickness compared to nominal design values.

Why does actual PCB resistance differ from calculated resistance?

Differences are caused by etching tolerance, plating uniformity, temperature effects, and manufacturing variability.

Can PCBBUY support low-resistance or high-current PCB designs?

Yes. PCBBUY provides controlled etching, copper thickness monitoring, and engineering support for resistance-sensitive PCB applications.

Industry Category