Understanding PCB Via Aspect Ratio

By:PCBBUY 08/25/2025 15:29

Introduction to PCB Via Aspect Ratio

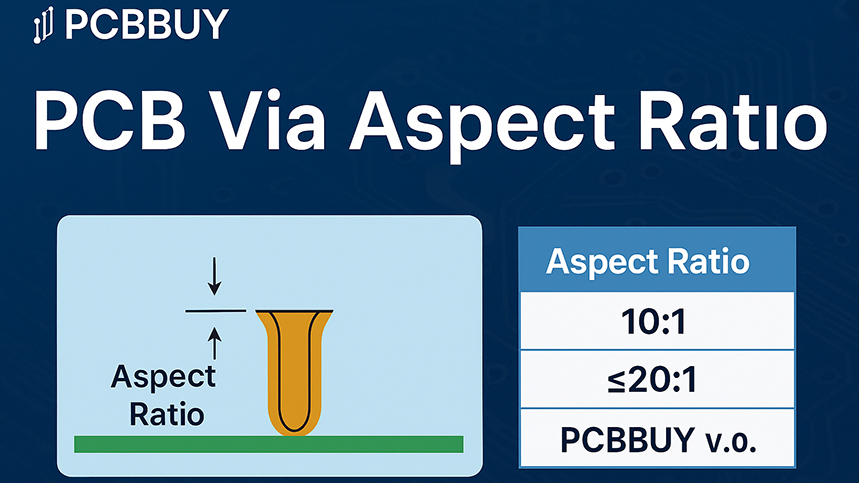

In the world of printed circuit boards (PCBs), the design of vias plays a crucial role in ensuring both functionality and reliability. Among all the parameters that define via performance, PCB via aspect ratio is one of the most important. Aspect ratio refers to the proportion between the thickness of the PCB and the diameter of the via drilled into it.

At PCBBUY, we understand that achieving high aspect ratios requires advanced drilling, plating, and inspection technologies. Our manufacturing capabilities allow us to handle challenging via designs, providing reliable solutions for high-density and high-performance electronic applications.

What Is PCB Via Aspect Ratio?

The PCB via aspect ratio is defined as:

Aspect Ratio = PCB Thickness ÷ Via Diameter

For example, if a PCB has a thickness of 1.6 mm and a drilled via diameter of 0.2 mm, the aspect ratio would be 8:1. This calculation illustrates the relationship between board thickness and hole size, helping engineers evaluate manufacturability and plating reliability.

At PCBBUY, our standard aspect ratio capability is 10:1, and with advanced process customization, we can achieve up to 20:1 depending on specific project requirements.

Why PCB Via Aspect Ratio Matters

The aspect ratio of a via is not just a mathematical value—it directly impacts PCB performance and reliability.

-

Copper Plating Uniformity: Higher aspect ratios make it harder for plating solutions to reach the inner walls of the via, leading to uneven copper thickness.

-

Electrical Reliability: Insufficient plating in deep vias can cause increased resistance or even open circuits under stress.

-

Mechanical Strength: Vias with poor plating quality may crack during thermal cycling, especially in automotive or aerospace applications.

-

Design Flexibility: A controlled aspect ratio allows for smaller via diameters, supporting high-density interconnects (HDI) and miniaturization.

Industry Standards for PCB Via Aspect Ratio

According to IPC and industry best practices:

|

PCB Type |

Typical Aspect Ratio |

Advanced Aspect Ratio |

|

Standard Through-Hole PCB |

6:1 – 8:1 |

10:1 |

|

HDI Blind/Buried Vias |

1:1 – 1.5:1 |

2:1 |

|

Advanced Multilayer PCBs |

10:1 |

Up to 20:1 (PCBBUY) |

PCBBUY’s manufacturing capability not only meets IPC standards but also provides customization for high-end applications. With our ≤20:1 aspect ratio capability, we are equipped to handle some of the most challenging PCB designs in the market.

PCB Via Aspect Ratio Manufacturing Process at PCBBUY

1. Precision Drilling

-

High-speed CNC drilling machines achieve micron-level accuracy.

-

Laser drilling is used for microvias and HDI boards, supporting aspect ratios as low as 1:1 for blind vias.

2. Copper Plating and Hole Wall Treatment

-

Uniform plating distribution is achieved with advanced chemical baths and pulse plating techniques.

-

Optimized pre-treatment ensures smooth hole walls and reliable copper adhesion.

3. Inspection and Quality Control

-

Cross-section analysis verifies plating thickness across via depth.

-

X-ray inspection detects hidden voids and defects in buried vias.

-

TDR (Time Domain Reflectometry) ensures impedance consistency in high-speed PCBs.

4. Capability Highlights

-

Standard aspect ratio: 10:1

-

Customized aspect ratio: up to 20:1

-

Microvia capability: ≤75 µm laser-drilled vias for HDI boards

PCB Via Aspect Ratio in Advanced Applications

The importance of via aspect ratio becomes more pronounced in high-performance industries:

-

HDI PCB: Required for smartphones, tablets, and IoT devices where miniaturization and high density are critical.

-

High-Speed PCBs: Stable aspect ratios ensure signal integrity in 5G, data centers, and telecom applications.

-

Automotive Electronics: Reliable vias withstand vibration, high temperatures, and thermal cycles.

-

Aerospace & Defense: Extreme reliability required for mission-critical systems.

PCBBUY has extensive experience in serving these industries with robust via aspect ratio management.

PCBBUY’s Advantage in PCB Via Aspect Ratio Manufacturing

-

High-end drilling technology: Capable of handling microvias and deep vias with extreme accuracy.

-

Advanced plating systems: Ensures reliable copper coverage even at high aspect ratios.

-

Strict inspection standards: AOI, X-ray, and cross-section analysis guarantee via integrity.

-

Customized solutions: From standard 10:1 to customized ≤20:1 aspect ratios for specialized applications.

With these capabilities, PCBBUY stands as a trusted partner for companies that demand precision and reliability in their PCB manufacturing.

Conclusion

The PCB via aspect ratio is a fundamental parameter in PCB design and manufacturing that directly affects electrical performance, reliability, and product lifetime. While many manufacturers can achieve a standard 6:1 or 8:1 ratio, PCBBUY’s advanced capabilities allow us to consistently deliver 10:1 aspect ratios and even customized solutions up to 20:1.

If you are looking for a reliable partner with advanced via technology, PCBBUY provides the expertise, equipment, and quality assurance to meet your most demanding requirements.

Contact PCBBUY today to discuss your project needs and experience the difference in advanced PCB manufacturing.

Industry Category