What Are the Classifications and Production Technologies of PCB CCL?

By:PCBBUY 04/11/2024 15:21

Copper-clad laminate (CCL) and its manufacturing method Copper-clad laminate (CCL) is a substrate for the production of PCB, which in addition to supporting various components, can also achieve electrical connection or electrical insulation between them.

The PCB manufacturing process is to impregnate glass fiber fabric, glass fiber felt, paper and other reinforced materials with epoxy resin, phenolic resin and other adhesives, dry at the appropriate temperature to the semi-curing stage, to obtain pre-impregnated materials (referred to as impregnated rubber), and then they are laminated with copper foil according to the process requirements, heating and pressurizing on the laminate machine to obtain the required Copper clad laminate(CCL).

What Are the Basic of ccl?

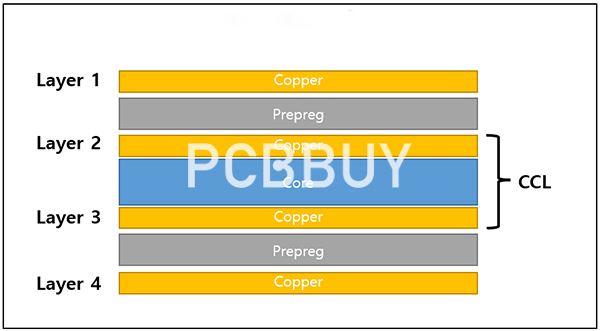

CCL provides the starting point for rigid PCB fabrication. The basic construction consists of:

·Central insulating core layer

·Copper foil laminated to one or both sides

·The core is pre-impregnated (prepreg) with adhesive resin

How to Classify CCL in Different Standard?

Classification and type of Copper clad laminate(CCL) Copper clad laminate(CCL) consists of four parts: copper foil, reinforcing material, binder and inorganic filler. Copper clad laminate(CCL)s are usually classified by reinforcement material type, adhesive type, substrate characteristics and application.

Classification by Reinforcement Material Category

The most commonly used reinforcing materials for Copper-clad laminate (CCL)s are non-alkali (the mass fraction of alkali metal oxides does not exceed 0.5%) glass fiber products (such as glass fabric, glass felt) or paper (such as wood pulp paper, bleached wood pulp paper, cotton wool paper). Therefore, Copper-clad laminate (CCL)s can be divided into two categories: glass fabric base and paper base.

Classification by Adhesive Type

The adhesive used in the foil coating board mainly includes phenolic, epoxy, polyester, polyimide, polytetrafluoroethylene, etc. Therefore, the foil coating board is also divided into phenolic foil, epoxy foil, polyester foil, polyimide foil and polytetrafluoroethylene foil.

Classification by Substrate Characteristics and Applications

According to the burning degree of the substrate in the flame and after leaving the fire source, it can be divided into general type foil board and self-extinguishing type foil board. According to the bending degree of the substrate can be divided into rigid foil board and flexible foil board: according to the working temperature and working environmental conditions of the substrate can be divided into heat resistant foil board, radiation resistant foil board, high frequency foil board and so on. In addition, there are foil boards used in special occasions, such as prefabricated inner foil boards, metal base foil boards, and according to the types of foil can be divided into copper foil boards, nickel foil boards, silver foil boards, aluminum foil boards, copper foil boards, beryllium copper foil boards.

Commonly Used Foil-covered Board Models

According to the provisions of GB/ T4721-1992, Copper clad laminate(CCL)s are generally represented by a combination of five English letters. The first letter C stands for copper foil. The second, three or two letters indicate the adhesive resin selected for the substrate, for example: PF means phenolic; EP means epoxy: UP means unsaturated polyester: SI means silicone: TF means polytetrafluoron: PI means polyimide: BT means bismaleimide triazine. The fourth and five letters indicate the reinforcing material used in the substrate, for example: CP indicates cellulose fiber paper; GC means alkali-free glass fiber fabric; GM stands for alkali-free glass fiber felt; AC stands for aromatic polyamide fiber fabric; AM stands for aromatic polyamide fiber felt.

If the inner core of the substrate coated with foil is cellulose paper as the reinforced material, and the two surfaces are affixed with alkali-free glass fabric, G can be added after CP.

The two digits on the right of the short horizontal line in the model indicate the product number of the same type but different performance. For example, the number of copper-clad phenolic paper laminates is 01 to 20. The number of copper-clad epoxy paper laminates is 21 to 30. Copper clad epoxy glass fabric laminate numbered 31~40: copper clad epoxy synthetic fiber fabric or felt laminate numbered 41~50; Copper-clad polyester glass fiber fabric or felt laminate numbered 51~60; High temperature clad copper foil laminates numbered 61~70; High frequency Copper-clad laminate (CCL)s are numbered 71~80.

If the letter F is added after the product number, it means that the coated foil is flame retardant.

Method for Manufacturing Copper Clad Foil Laminate

The manufacture of Copper clad laminate(CCL) mainly consists of three steps: preparation of resin solution, dipping of reinforcement material and pressing molding.

The main raw material for manufacturing Copper-clad laminate (CCL)s

The main raw materials of Copper-clad laminate (CCL) are resin, impregnated paper, alkali-free glass fabric and copper box.

Resin

The resin used for Copper-clad laminate (CCL) includes phenolic resin, epoxy resin, polyester resin, polyimide resin, etc., of which phenolic resin and epoxy resin are the largest.

Phenolic resin is a kind of resin formed by condensation of phenols and aldehydes in acidic or alkaline medium. Among them, the main raw materials of paper-based coated foil are resin polycondensation of phenol and formaldehyde in alkaline medium. In the manufacture of paper-based foil board, in order to obtain various boards with excellent properties, it is often necessary to modify phenolic resin, and strictly control the content of free phenol and volatile matter in the resin, so as to ensure that the sheet will not be stratified and foaming under thermal shock.

Epoxy resin is the main raw material of glass fabric cladding board, it has excellent bonding properties and electrical and physical properties. More commonly used are E-20, E-44, E-51 and self-extinguishing E, -20, E.25. In order to improve the transparency of the foil-coated substrate in order to check the graphic defects in the printed circuit board production, the epoxy resin should have a lighter color.

Impregnated Paper

Commonly used impregnated paper are lint paper, wood pulp paper and bleached wood pulp paper. Lint paper is made of short fiber cotton fiber, which is characterized by better penetration of resin, and the blanking and electrical properties of the produced sheet are also better. Wood pulp paper is mainly made of wood fiber, generally lower price than cotton paper, and higher mechanical strength, the use of bleached wood pulp paper can improve the appearance of the board.

In order to improve the properties of sheet, the thickness deviation, standard weight, breaking strength and water absorption of impregnated paper need to be guaranteed.

Alkali Free Glass Fabric

Alkali-free glass fabric is a reinforced material of glass fabric substrate coated foil board, and quartz glass fabric can be used for special high-frequency applications.

The IEC standard stipulates that the alkali metal oxide (Na, O) content (mass fraction) of non-alkali glass fabric is not more than 1%, JIS standard R3413-1978 stipulates no more than 0.8%, Soviet standard stipulates no more than 0.5%, and China's standard JC/ T170-2012 stipulates no more than 0.8%. In order to meet the needs of universal, thin and multi-layer PCB, the models of glass fabric for foil coating have been serialized abroad. Its thickness ranges from 0.025 to 0.234mm. In order to improve the machining performance of epoxy glass fabric coated foil board and in addition to low board cost, non-woven glass fiber fabric (also known as glass felt) has been developed in recent years.

Copper Foil

The foil of the foil board can be copper, nickel, aluminum and other metal foils. However, from the conductivity of metal foil, weld ability, elongation, adhesion ability to the substrate and price, in addition to special uses, copper foil is the most suitable.

Copper foil can be divided into calendared copper foil and electrolytic copper foil. Rolled copper foil is mainly used in flexible PCB and some other special purposes. Electrolytic copper foil is widely used in the production of foil-covered boards. For the purity of copper, IEC-249-34 and our national standards stipulate that it shall not be less than 99.8%(mass fraction).

At present, the thickness of copper foil for PCB is mostly 35μm and 18μm. With the refinement of printed circuit board circuits, thinner copper foils such as 12μm, 9μm, and even 3μm have been commercialized. However, for the printed circuit board for automotive electronics that needs to carry current, the thickness requirement for copper foil is thicker, such as 70μm, and even 300μm copper foil has also been marketed.

In order to improve the bonding strength of copper foil to the substrate, black or brown copper foil is usually used (that is, after oxidation treatment, a layer of copper oxide or cuprous oxide is generated on the surface of copper foil, which improves the bonding strength of copper foil and substrate due to polarity) or coarser copper foil (using electrochemical methods to generate a coarser layer on the surface of copper foil, increasing the surface area of copper foil). Due to the anchoring effect of the coarsening layer on the substrate, the bonding strength of copper foil and substrate is increased). In order to avoid moving to the substrate due to the copper oxide powder falling off, the treatment method of the copper foil surface is also constantly improving.

For example, TW type copper foil is board with a thin layer of zinc on the coarsening surface of copper foil, and the surface of copper foil is gray; TC type copper foil is board with a thin layer of copper-zinc alloy on the coarser surface of copper foil, and the surface of copper foil is golden yellow. After special treatment, the thermal discoloration resistance, oxidation resistance and cyanide ability of copper foil in printed circuit board manufacturing can be improved accordingly.

The surface of the copper foil should be smooth and clean, without obvious wrinkles, oxidation spots, scratches, pitting, pits and stains. The porosity of 305g/m² and above copper foil requires no more than 8 penetration points in an area of 300mmx300mm; The total pore area of copper foil on an area of 0.5m does not exceed the area of a circle with a diameter of 0.125mm. The porosity and pore size of copper foils below 305g/m² shall be agreed by the supply and demand parties. The weight and thickness per unit area of copper foil must comply with the requirements in Table below.

|

Mass per unit |

Thickness |

||||

|

Nominal value(g/m²) |

Deviation(%) |

Nominal value/μm |

Deviation/μm |

||

|

Precision board |

Ordinary board |

Precision board |

Ordinary board |

||

|

152 |

±5 |

±10 |

18 |

±2.5 |

±5 |

|

230 |

±5 |

±10 |

25 |

±2.5 |

±5 |

|

305 |

±5 |

±10 |

35 |

±2.5 |

±5 |

|

610 |

±5 |

±10 |

70 |

±2.5 |

±5 |

|

915 |

±5 |

±10 |

105 |

±2.5 |

±5 |

1. Copper foil with a thickness of 50μm is a transition product and is not used as a recommended specification.

2. For reference only.

Before the copper foil is put into use, the sample is taken for pressing test if necessary. Pressing tests can show its peeling strength and general surface quality.

Production Technology of Copper-clad Laminate (CCL)

The production process of Copper clad laminate(CCL) is as follows:

Resin synthesis and adhesive solution preparation → reinforced material dipping and drying → material cutting and inspection → material and copper pin lamination → hot pressing → cutting → inspection and packaging.

The synthesis and preparation of the resin solution are carried out in the reactor. Most of the phenolic resins used in paper-based box boards are synthesized by foil factories.

The production of glass fabric-based coated foil board is to dissolve the epoxy resin provided by the raw material factory and the curing agent in the acetone or dimethylformamide, ethylene glycol methyl ether, and stir it to become a uniform resin solution. The resin solution can be used for dipping after curing for 8~24h.

Gluing is done on the gluing machine. Dipping machine divided into horizontal and vertical two kinds. Horizontal dipping machine is mainly used for impregnating paper, vertical dipping machine is mainly used for impregnating glass fabric with higher strength. Resin impregnated paper or glass fabric, through the extrusion roller into the drying channel after drying, cut into a certain size, pass the inspection reserve.

According to the requirements of the product design, the copper foil and the impregnated paper or glass fabric are laminated, placed in the middle of two stainless steel boards with release film or release agent, and the laminated sheet together with the steel board is pressed in the hydraulic press.

Qualified foil-covered boards shall be packaged. A layer of low-sulfur insulation paper should be placed between every two double-sided foil boards, and then packed in polyethylene plastic bags or covered with moisture-proof paper. In the process of transportation and storage, the foil-covered board should be placed flat away from the ground and prevent rain, high temperature, direct sunlight and mechanical damage.

The temperature of the foil-covered warehouse should not exceed 35 ° C, the relative humidity should not be greater than 75%, and there is no corrosive gas. The storage period of the foil-covered board is one year from the date of discharge, and the qualified person can still be used after the expiration of the period according to the technical requirements.

Copper Clad Laminate(CCL) Quality Control

Each batch of raw materials such as paper, glass fabric, resin, copper foil, dye and solvent should be inspected before production in order to produce a consistent quality foil-coated board. Only after passing the inspection can it be put into use, and it should be recorded in detail for verification.

The prepared resin liquid should continue to be stirred during use to make the resin liquid concentration uniform. The reinforcement material should have enough time to pass through the dipping tank to ensure the complete penetration of the resin to the reinforcement material to prevent defects such as lack of glue and delamination of the substrate. The impregnated material should be stored in a warehouse with a relative humidity of 30% to 50%, a maximum temperature of not more than 21 ° C and no catalytic effect (such as no ultraviolet irradiation and radiation environment).

When the board is forming, on the basis of ensuring the complete curing of the substrate, the molding temperature should not be too high to avoid the oxidation of the copper foil surface and the degradation of the polymer material. Excessive release agent should not be applied on the stainless steel board, so as not to pollute the surface of the foil-covered board. Anyone who touches the copper foil should wear clean gloves to ensure that there are no fingerprints and stains on the surface of the copper foil.

Reference

He Wei, PCB Basic Electrical Information Science and Technoloy, China Machine Press,20-25

Industry Category