BGA 4 Layer PCB Manufacturing with Precision, Quality, and Advanced Capabilities

By:PCBBUY 08/14/2025 15:09

Introduction to BGA 4 Layer PCB

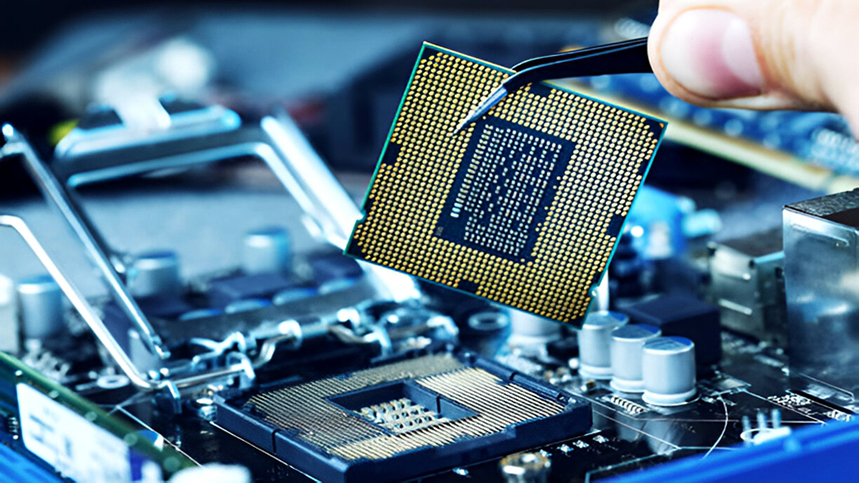

Ball Grid Array (BGA) is a high-density surface mount packaging technology widely used in modern electronics, enabling superior electrical performance and space efficiency. In many designs, the BGA 4 layer PCB configuration is preferred because it balances complexity, performance, and cost-effectiveness.

At PCBBUY, we specialize in manufacturing high-quality BGA 4 layer PCBs with precise control over pad size, via technology, and layer stack-up. Our advanced facilities can achieve BGA pads as small as 0.25 mm, making us an ideal partner for high-density, fine-pitch applications.

Key Features of BGA 4 Layer PCB

A standard BGA 4 layer PCB from PCBBUY typically features:

-

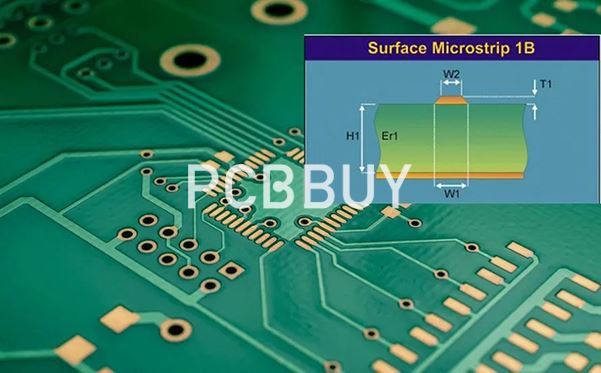

Layer Stack-up: Optimized for signal integrity and power delivery, often in the configuration:

-

Top Signal Layer

-

Ground Plane

-

Power Plane

-

Bottom Signal Layer

-

Smallest BGA Pad Size: 0.25 mm minimum pad diameter, enabling ultra-fine pitch assembly.

-

High Routing Density: Capability to handle 0.1 mm line/space for fine-pitch BGA devices.

-

Material Options: FR4 high-Tg, low Dk/Df laminates for high-speed signal performance.

-

Surface Finishes: ENIG, ENEPIG, OSP — all suitable for high-reliability BGA soldering.

BGA Soldering Challenges and PCB Design Considerations

Designing for BGA 4 layer PCBs requires precise attention to detail:

-

Fine Pitch Accommodation: For devices with pitch as low as 0.4 mm, via-in-pad and microvia technology are often necessary.

-

Via Technology: Blind and buried vias enable breakout routing without sacrificing signal quality.

-

Solder Mask Definition: PCBBUY applies SMD-defined pads to prevent solder bridging and ensure proper ball wetting.

-

Thermal Management: Balanced copper design and controlled via filling improve heat dissipation.

By integrating via-in-pad plating and precise solder mask alignment, PCBBUY ensures excellent solder joint reliability, even for the most demanding BGA designs.

Manufacturing Process for BGA 4 Layer PCB at PCBBUY

We follow a rigorous manufacturing process to ensure high yield and performance:

-

Layer Stack-up & Lamination — Multi-stage lamination with tight layer-to-layer registration control.

-

High-Precision Drilling — Laser drilling for microvias, mechanical drilling for through-holes with ±0.05 mm tolerance.

-

Copper Plating & Via Filling — Ensures flat pad surfaces for BGA soldering and consistent copper thickness.

-

Solder Mask Application — High-resolution imaging to guarantee mask alignment within ±0.025 mm.

-

Surface Finish — Applying ENIG or ENEPIG for superior solderability and oxidation resistance.

-

Electrical Testing — 100% E-test to verify connectivity and impedance accuracy.

Quality Control and Testing for BGA 4 Layer PCB

-

X-ray Inspection: Detects internal solder joint alignment and voids.

-

TDR (Time Domain Reflectometry) Testing: Ensures impedance compliance within ±10% tolerance.

-

Automated Optical Inspection (AOI): Detects trace width variations and solder mask defects.

Every BGA 4 layer PCB from PCBBUY undergoes full functional and dimensional inspection to guarantee performance.

Applications of BGA 4 Layer PCB

Our BGA 4 layer PCB solutions are widely used in:

-

Smartphones and tablets

-

Networking and telecommunication devices

-

Industrial control systems

-

Medical diagnostic and imaging equipment

-

High-performance computing modules

Why Choose PCBBUY for Your BGA 4 Layer PCB Projects

-

0.25 mm smallest pad capability for ultra-fine pitch BGAs

-

0.1 mm minimum trace/space for high-density designs

-

ISO, UL, and RoHS certified production processes

-

Fast prototype turnaround — as quick as 24 hours for urgent projects

-

Experienced engineering support for design optimization and cost reduction

Conclusion

The BGA 4 layer PCB is a critical foundation for modern, high-performance electronics. At PCBBUY, we combine cutting-edge manufacturing technology, stringent quality control, and skilled engineering expertise to deliver PCBs that meet the highest standards in precision and reliability.

Whether your design involves high-speed signals, ultra-fine pitch BGAs, or complex stack-ups, PCBBUY has the capability to turn your concept into reality — on time and within specification.

Contact PCBBUY today to get your custom BGA 4 layer PCB quote.

Industry Category