PCB Press Fit Hole Calculator Guide Ensures Precision in Manufacturing

By:PCBBUY 11/20/2025 11:33

Press-fit interconnection technology relies on controlled interference between a compliant-pin structure and a plated through-hole (PTH). Achieving reliable mechanical retention and electrical stability requires a precise dimensional relationship, which is typically evaluated using a press fit hole calculator. This article provides a technical overview of how press-fit hole dimensions are determined and how PCBBUY maintains strict tolerance control in production.

At PCBBUY, precise hole tolerance control has always been one of our core strengths. In this guide, we explain how press-fit holes work, how calculators determine the proper dimensions, and how PCBBUY guarantees consistent quality from prototype to mass production.

What Is a Press-Fit Hole and Why the Press Fit Hole Calculator Matters?

A press-fit hole is a plated through-hole (PTH) designed to hold a compliant or solid press-fit pin. The fit must create just the right amount of interference so the pin is firmly retained without damaging the PCB.

Why is a press fit hole calculator important?

Because even tiny deviations—only a few microns—can affect mechanical strength, retention force, and long-term reliability. A calculator helps engineers determine the hole size based on pin diameter, plating thickness, and tolerance requirements.

Key Factors Considered in a Press Fit Hole Calculator

A good calculator typically evaluates:

-

Pin diameter (nominal & tolerance)

-

Final hole size

-

Copper plating thickness inside the barrel

-

Surface finish (ENIG, Immersion Tin, OSP, Tin-Lead)

-

Interference fit range recommended by IPC

-

Material elasticity of the PCB

These parameters determine whether the PCB can withstand mechanical insertion without cracking or delamination.

How Press Fit Hole Sizes Are Determined?

The final hole dimension is influenced by:

-

Drilling accuracy

-

Copper plating growth during PTH

-

Surface finish thickness

-

Material expansion under heat

A calculator typically outputs:

-

Recommended drill size

-

Final plated diameter

-

Allowable tolerance

-

Expected retention force

This information guides engineers to select the optimal combination of drill bit and plating spec.

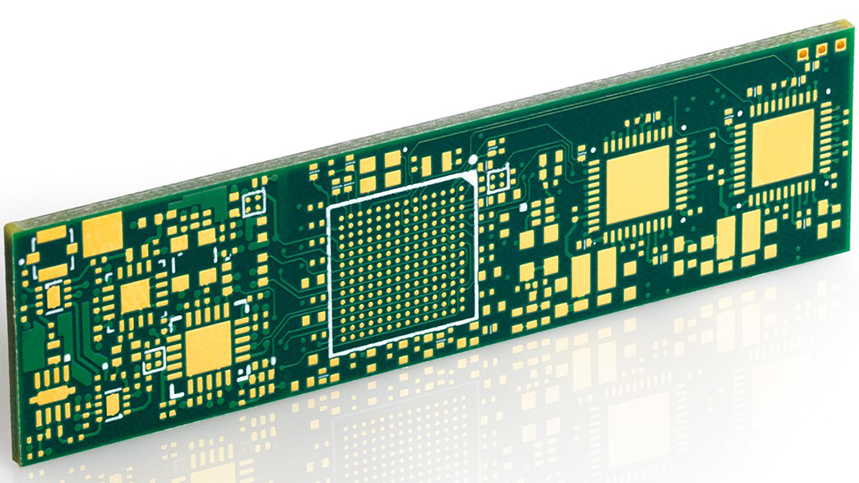

PCBBUY’s Capabilities in Press-Fit Technology

PCBBUY has strong experience in manufacturing press-fit PCBs for automotive, industrial, and telecom applications. Our capabilities include:

-

High-precision CNC drilling with ±0.03 mm consistency

-

Strict plating thickness control, ensuring accurate final hole sizes

-

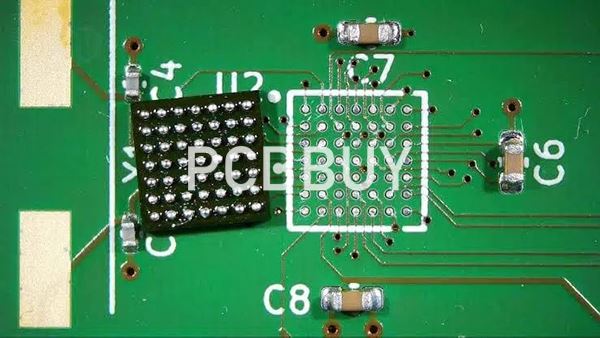

Full microsection inspection to verify barrel thickness and concentricity

-

Advanced hole-size measurement using AOI + microscope metrology

-

Support for ENIG, Immersion Tin, Tin-Lead finishes used for press-fit

-

Engineering consultation based on thousands of delivered press-fit projects

Our manufacturing team adjusts drill size, plating parameters, and hole compensation to ensure the perfect interference fit for each customer’s connector type.

How to Use a Press Fit Hole Calculator?

-

Input the pin diameter and tolerance.

-

Select the desired interference fit (usually 0.05–0.12 mm).

-

Enter plating thickness and surface finish.

-

The calculator outputs:

-

Recommended drill bit

-

Expected finished hole size

-

Fit classification

-

Retention force prediction

If you are unsure about any parameter, PCBBUY engineers can help review your connector datasheet and recommend the ideal values.

Common Press-Fit Problems & How PCBBUY Prevents Them

Typical issues include:

-

Hole cracking

-

Too-tight interference

-

Weak insertion retention

-

Copper barrel fracture

-

Pin alignment deviation

PCBBUY prevents these with:

-

Controlled plating growth curves

-

Microsection analysis for every batch

-

Statistical Process Control (SPC)

-

Continuous drill compensation feedback

This ensures a stable and highly reliable press-fit structure.

Why Choose PCBBUY for Press-Fit PCBs?

-

Advanced drilling + plating accuracy

-

Engineering support for pressing calculations

-

Consistent mass production stability

-

Proven experience across automotive and telecom industries

-

Fast production lead time with guaranteed tolerance control

If your project requires accurate press-fit holes, PCBBUY is fully equipped to deliver the quality and precision you need.

FAQ

Q1: How much interference is recommended?

Typically between 0.05–0.12 mm, depending on pin type.

Q2: Which surface finish is best for press-fit?

Immersion Tin and Tin-Lead are commonly preferred; ENIG is also used depending on the pin design.

Q3: Can PCBBUY help optimize my hole size?

Yes. Provide your connector datasheet and we will adjust drill size and plating spec accordingly.

Q4: What materials are suitable for press-fit PCBs?

FR4 high-Tg materials are commonly used due to better mechanical strength.

Industry Category